3D printers, just like other mechanical devices, need routine maintenance practices for the best performance.

As an Amazon Associate, I earn from qualifying purchases. If you make a purchase after clicking on a link I may earn a small commission at no extra cost to you.

If not maintained properly, they may start producing squeaking and grinding sounds from the screw and the bearings. This will affect the quality of the printouts.

Quick Navigation

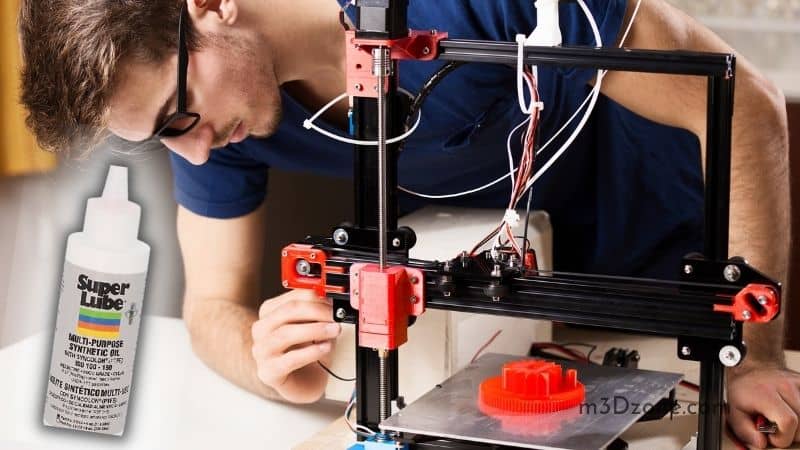

3D printer maintenance doesn’t involve cleaning and tightening nuts and belts only; you’re supposed to lubricate movable parts and metallic joints as well.

For example, you may experience ripples while printing on your 3D printer due to uncontrolled rod movement. To fix this issue, you need to lubricate the threaded rods to reduce friction when it moves.

However, when applying lubricant to the various parts of your 3D printer, you need to know which lubricant works best for the given part and how to apply it.

Other things you need to know are the parts of the 3D printer you should lubricate, the properties of a good lubricant, and when and how often you need to lubricate your 3D printer.

Regular and well-practiced lubrication will improve the 3D printer’s durability and quality of the printouts.

Lubricate 3D Printer. Why Lubricating Is Important!

Lubricants serve the general purpose of reducing friction in moving parts. This is important in ensuring the parts move smoothly, reducing wear and tear, and thus improving the parts’ lifespan.

Usually, the lubricated parts are metallic, but with the specialty lubricants, plastic components can also be lubricated.

Lubricants also reduce the corrosion of metallic parts by acting as a barrier between the metal and air. Corrosion affects the coherence of metallic components reducing their efficiency.

The print head of the 3D printer moves frequently and needs to be lubricated for high efficiency. Connected to it are the rails, pulleys, and belts, which, to move smoothly, need to be lubricated. The print head moves in both x, y, and z axes.

What Parts of a 3D Printer Need to Be Lubricated?

All moving parts within the 3D Printer need to be lubricated. However, there are some parts that you need to put more emphasis on; they need regular lubrication.

The first parts are the X, Y, and Z-axis. These axes direct the print head to move and determine the hot end of the nozzle when printing.

The X and Y axes move horizontally, while the Z-axis moves vertically. By doing so, they are constantly moved from one position to another.

Applying a lubricant ensures smooth movement with no wear and tear.

The second part of being lubricated is the guide rail. The guide rail supports the Z-axis and has bearings made of either metal or plastic on metal.

The threaded steel rods and lead screws also need to be lubricated. Lubricating them ensures smooth movement within the 3D Printer.

You may not need to lubricate the stepper motors as they’re brushless; they don’t have brushes, so there is no need for repair or replacement.

Properties of a Good Lubricant

When choosing the lubricant to use in your 3D Printer, you should consider the following properties:

- Thermal stability: The lubricant you choose for your 3D Printer should not have its chemical composition broken down, lose its mechanical stability, or should not be oxidized when exposed to heat. This is because the lubricant will be exposed to intense heat in the 3D printer. If any of these happen, the lubricant will not be effective.

- Mechanical stability: The lubricant should be stable mechanically to withstand heat and friction force.

- Corrosion resistance: The lubricant should be able to protect the metallic parts by forming a film that eliminates oxidation.

- Consistency: The lubricant should have consistent properties. The National Lubricant Grease Institute measures this.

The lubricant should also have the ability to resist deterioration when exposed to high temperatures and withstand huge weights.

You should consider using lighter lubricants for your 3D printer.

This is because light lubricants allow for smooth movements of parts. On the other side, a heavy lubricant inhibits movements of parts despite creating a thicker layer for corrosion protection and its ability to withstand huge loads.

Choosing Between Oil or Grease Lubricants

You can use either oil or grease for lubrication. However, oil is a lighter lubricant compared to grease. It allows for smooth movements and is also easy to apply.

But, when exposed to heavy loads, the oil lubricant can’t withstand it. In such scenarios, it would be best to go for grease lubricants.

Therefore, the best lubricant for your 3D printer will be light but strong enough to withstand heavy loads.

Types of 3D Printer Best Lubricants

1. Polytetrafluoroethylene (PTFE) Lubricant

PTFE-based lubricants are primarily used to lubricate threaded rods for the X, Y or Z-axes. They are found in grease, olive oil, and dry solvent forms.

PTFE has a low drag coefficient (surface friction of a compound) and can be used for metal-on-metal and plastic-on-metal contacts. The PTFE has several brands of lubricants:

a) Super Lube Lubricant

The most common brand of a PTFE-based lubricant is the Super Lube. It’s an ISO-grade synthetic lubricant and has a wide range of applications.

The Super Lube adequately adheres to the surfaces it is applied to and prevents corrosion and wear due to friction.

b) White Lithium Grease

Another brand of PTFE lubricant is the Lithium Grease lubricant. It’s also called white lithium grease.

The lithium grease is made of lithium soap, oil, and additives mixture and is ideal for lubricating guide rails and rods of 3D printers. The lithium grease provides extra viscosity that makes the lubricant strong for heavy loads.

2. Graphite Powder Lubricant

A graphite powder lubricant can repel dust particles and dirt and remains intact when applied. The graphite in the lubricant gives it these properties. It’s more superior and expensive than other lubricants and is similar to Teflon lubricant.

The graphite powder lubricant does not have oil; instead, it has a volatile solvent that evaporates when the lubricant is applied to the 3D part.

A thin lubricating dry graphite film resembling a black primer is left behind and has conductivity properties. You should, therefore, avoid using this lubricant near active electronics as they short out components. Avoid using the aerosol version near the 3D printer.

Graphite powder lubricant is ideal for metal-to-metal applications, especially lead screws. It is not the favorite for plastic components as they are too abrasive.

3. 3-in-one Multi-purpose Oil

3-In-One Multi-Purpose Oil has an immediate effect on noise reduction in moving parts.

It’s used in the manufacturing process of 3D printers. Unlike other lubricants, 3-In-One Multi-Purpose Oil has no odor.

It can also be used to lubricate the linear bearings on your 3D Printer. It improves the durability of components of the 3D Printer.

4. Silicone Lubricant

Silicone lubricant is ideal for use in treadmill belts. They can be applied in metal-to-plastic components, plastic, and rubber.

You should note that the silicone lubricants are not meant to be applied in metal-to-metal parts of the 3D.

Ensure you know the parts of your 3D printer well before using this lubricant.

5. Teflon Dry Lubricant

Teflon lubricant (check at Amazon) is best when lubricating lead screws. It has a thin coating that repels dirt, lowers friction, and prevents corrosion. It is similar to silicone, only that it doesn’t leave a sticky residue on the surface it is applied.

It is found in both liquid form and aerosol cans. The can evaporates to leave a dry Teflon lubricating powder.

The powder form has a low friction coefficient.

The Teflon dry lubricant is non-toxic and therefore safe for use, although it’s non-biodegradable.

6. Molybdenum Disulphide Lubricant

Molybdenum Disulphide Lubricant (MolyD) is similar to graphite lubes. It is meant to be used in metal-to-metal contacts only.

Do not use it in plastic components as they have solid additives (graphite) that may compromise the structural composure of the plastics.

The molybdenum disulfide lubricant does not have conductivity properties; therefore, it’s safe to use near electronics.

7. Tungsten DiSulphide (WS2) Lubricant

NASA invented tungsten disulfide lubricant for the best lubrication for their spaceships.

It has a lower drag coefficient than the Polytetrafluoroethylene lubricant.

How to Lubricate Your 3D Printer

The lubrication process is the same for all the lubricants you may use for your 3D Printer. Here’s what you should do:

- Begin by cleaning all the 3D Printer moving parts to be lubricated. Clean the guide rail, rods, and belts. When cleaning, use rubbing alcohol and paper towels. If you want to clean the threaded rod, be sure to have a toothbrush and rubbing alcohol. After finishing cleaning, wait for the parts to dry before proceeding. Do not use Acetone because it’s corrosive and will damage plastic parts of the 3D Printer.

- Spray the lubricant on the surface of the part at equal distances, let’s say 5 inches intervals. Apply a small amount the first time.

- Use a rubber glove (check at Amazon) to spread the lubricant. Do not use bare hands as the lubricant may have toxic elements.

- Use the 3D printer’s motor controls to move the lubricated parts. You can also move the parts manually. Nudge the nozzle along the axes several times to spread the lubricant evenly and distribute them to all the crannies and nooks.

- Ensure you do not apply excess lubricant. Too much lubricant inhibits the movement of components, thus straining the motor. Using paper towels, wipe out excess lubricants.

- The final step is to rerun the printer to its default axes.

How Often Should I Lubricate My 3D Printer?

Knowing how often to lubricate your 3D is very important. The frequency at which you lubricate your 3D printer may vary depending on several factors, like the type of lubricant you’re using and the temperature at which you run your 3D printer.

When do I need to lubricate my 3D printer? If you hear a squeaking sound from the rods when the print head moves on them, then the 3D printer needs to be lubricated.

You may also experience resistance to movement or an increase in temperature conditions in the 3D printer.

Whenever this happens, you should pause printing and lubricate the 3D printer before proceeding because an unlubricated printer will produce low-quality printouts.

You should also be keen on the place you put your 3D printer. If the 3D printer is in a dusty surrounding, the dust particles may stick on the lubricants applied to the 3D printer reducing their effectiveness.

In such a case, you’ll need to clean up and lubricate the parts again.

How often you lubricate your 3D printer may also depend on how frequently you use it. If you use your 3D printer more often, you might need to lubricate it more.

Otherwise, lubrication exercise once every month is a good way to go.

Also, ensure to liaise with your 3D printer manufacturer or the lubricant manufacturer to determine how often you need to lubricate the 3D printer.

However, you are supposed to be keen on the performance of your 3D Printer to determine the most appropriate times it needs lubrication.

Final Thoughts

The 3D printer has a lot of moving parts. In the process, friction builds up when moving parts are in contact.

Just like any other machine, the 3D printer’s parts may wear out or tear. Lubricating the moving parts, metallic parts, rubbers, and plastic has proven to be the main solution to these issues, if not parts replacement.

The 3D printer also works under high temperatures. The moving parts grinding on each other causes friction that produces a lot of heat. The produced heat is directed to the stepper motors, making them take in more heat than required, leading to damage.

Having the right knowledge on the types of lubricants, when you need to apply them, and how often you are supposed to apply the lubricant is all you need to keep your 3D Printer going.

Follow a routine lubrication exercise as part of your maintenance practice for quality printouts and longer 3D printer life.

Recommended Reading

3D Print Warping. Easy Fixes and Ways to Prevent It!

What is 3D print warping? Warping lies as one of the most common problems you may encounter in 3D printing and very frustrating. Luckily, some measures will help...

Easy Guide to Start with Non-Planar 3D Printing

Non-planar 3D printing is a relatively new technology that produces smooth surfaces on nonplanar surfaces. Let's find out more inside!

How Much Filament Is Used in 3D Printing?

Larger 3D figures consume more printing filament than smaller models. The type or brand of printer you are using also determines how much filament you will use.