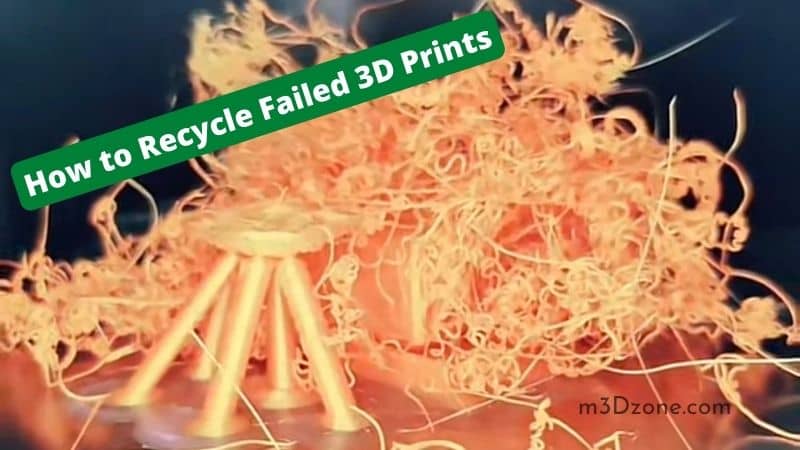

3D prints tend to fail during printing, especially when testing a new filament.

You could also produce waste 3D prints when adjusting your machine or during an ordinary accident. Whichever the case, you’ll always have some failed 3D filaments. So let’s see how to recycle failed 3D prints in the most easy ways.

Quick Navigation

So, what do you do with the heap of waste prints in your workshop’s junkyard? Do you throw them away like any other trash? It feels wrong, and your hands will definitely shy away from doing this!

Thankfully, there’re tons of recycling ideas to help you make gold out of rubbish. This article takes you through these tactics and much more.

What Is a Filament Recycler?

3D prints recycler is a typical recycler that smashes failed prints into small pieces, melts them down, and pushes the liquid plastic through an outlet. The hot liquid is then allowed to cool and curved to form a roll.

When using your filament recycler, it’s essential to note the following:

- Mixing different types of filaments may result in undesirable printing results.

- Using plastics with different chemical compositions may yield substandard results. Hence, you need to have clean and separated filaments.

Since not all machines can handle shredding and extrusion, you may have to buy two machines for your 3D prints recycling.

Can You Recycle Failed 3D Prints or Do You Need a New Filament?

Yes. You can recycle failed 3D prints. However, some 3D printed plastics recycling methods are different from the standard plastics like water bottles – because they have different recycling qualities.

PLA and ABS are the types of 3D printer filaments that can’t be recycled, typically with other domestic items. Therefore, you need to send them to special facilities for recycling. Below are the various ways in which you can repurpose your 3D prints.

Create Something Neat

Combining two or more prints to form something new is one of the easiest ways of recycling your failed prints. This method is straightforward as all you need are simple supplies like tape or glue. For example, you may have soothing like low-poly Darth Vader or Yoda bust.

The good thing about this strategy is that you use what you have. You can also create a new, multicolored object by combining different colored prints.

Make ABS Juice, Slurry, Glue

This method applies exclusively to the Acrylonitrile Butadiene Styrene (ABS) filament. You can use acidic liquids to melt ABS prints because it’s oil-based.

By dissolving an ABS scrap in acetone, you may produce three different liquids with slightly different uses – ABS juice (stick parts to the bed), ABS slurry (filling small holes between 3D parts), and ABS Glue (welds or sticks two parts).

DIY Recycled Filament Machine

Recycling machines allow you to turn your failed prints into a brand new filament ready to reuse with the help of a recycling workflow known as a filament extruder.

There are three steps in filament extruding: smashing the failed prints, melting and extruding, and coiling the extrusion onto a new wheel.

Local Recycling (Plastic Waste)

PLA is environmentally friendly as it’s known for being biodegradable. However, the process may take decades if perfect conditions aren’t in place.

Although PLA degradation doesn’t release dangerous substances, a local recycling facility may avoid taking it – it’s tedious to sort it from other plastics.

For that reason, you can compost it at home or in an industrial facility. All that composting is done to speed up the natural decomposing process. The home option may take longer, but you’re doing your best to avoid disposing of your plastic waste.

What to Do With Failed Prints?

Repurpose Your Failed 3d Prints

Start by blending your leftover filament strands. Where you have large pieces, put them on a strong surface, wrap them with a towel, and crush them with a hammer to produce small chunks.

Next, put your ground-up filament pieces on shaped non-stick pans or a baking tray, and place them in a toaster oven or an oven until a melting point. The appropriate temperature for ABS is about 220℃ and 180-200℃ for PLA a filament extrusion process.

If your pan is too large, use a food-safe resin to cover the molten plastic to form a cutting board. Alternatively, you could grid your melted plastic to your preferred shapes. For example, you can have keychains, cardboard mats, or customized items.

Can You Reuse Failed Resin Prints?

You can reuse failed resin prints. However, it’s advisable not to pour the leftover into the original container to avoid contamination of unused resin. If you have to pour it back, remove the large pigments by filtering the consumed resin properly.

3D Printing Filament Recycling

Here, we look at the 3D recycling process for failed filaments.

Step 1: Shred your failed 3D straps into small pieces. Get a new or a second-hand shredder from nearby workshops or use a document or hand-cranked shredders or blender scissors. To produce the best results, have uniform straps.

Step 2: Dry your material in a self-built dry box.

Step 3: Extruding is the most essential step. You need an extruder workspace. This is how you can create one using the Precious Plastic Blueprint.

Step 4: The hot plastic produced by the extruder need to cool down. You can do so using water or air, but the air is the best choice – use a tower ventilator as water cooling is messy especially, for material less than 3kg.

Step 5: Once your extrusion gets cool, wind it onto a spool. Here you’ll need a filament wider with a guider, a pulling unit, and a turning spool axis. When purchasing or building one, the important factor is that filaments must remain on tension to avoid loose spools.

Making 3D Printer Filament From Plastic Bottles

You can create 3D printer filaments from plastic bottles. Nonetheless, you can only do so out of PET bottles.

You’ll require a special system that lets you extrude the plastic straps from your bottles. PETBOT is a perfect example. Below are a few steps to follow in converting your bottles into usable filament.

- Remove any external caps or seal and clean your bottles properly

- Vacuum seal the bottles and reduce their sizes by heating

- After cooling the bottles, use a pair of scissors or a saw to cut them into small chunks

- Shred the pieces into tiny pieces

- Put the pieces under 160°C temperature for 4 hours

- Feed the PET into a filament extruder

- Test your extrusion at different temperatures and nozzle diameters for great PET results.

Conclusion

There are several recycling strategies to help you deal with your failed print. Even if the process may seem tedious, it can save money in the long run.

Unlike in other manufacturing processes, in 3D printing, you don’t have to worry about damaged support materials.

With this resourceful article, you’ve no reason to keep mountains of failed 3D printed parts in your dustbin. Be environment-friendly by creating high-quality models with minimal or no waste.

Recommended Reading

3D Printer Maintenance. The Ultimate Checklist!

3D printer maintenance services ensure that the printer runs well and performs as intended. No more failed prints and enhance the 3D prints quality.

HIPS Filament. Guide for 3D Printing with HIPS.

HIPS filament, a supreme 3D printing support material, provides many opportunities for professionals and 3D printing enthusiasts. Read more!

What Is 3D Printing Gcode? Commands, Files, and More!

What exactly is 3D printing Gcode? The G-code is a programming language for instructing the functioning of 3D printers. Let's dive into it!