Sometimes, you may fail to get the best result from your 3D printer. The final print may turn out with rough edges because of the filament used or how you handle the 3D printing process.

As an Amazon Associate, I earn from qualifying purchases. If you make a purchase after clicking on a link I may earn a small commission at no extra cost to you.

Polyvinyl Alcohol (PVA) filament comes in as a support material that helps alleviate the challenge of final poor quality 3D prints.

Quick Navigation

It is a biodegradable polymer that remains sensitive to moisture. Interestingly, this same quality makes it a great support filament for 3D printing.

After printing a 3D model, you need to submerge it in water, and because PVA easily dissolves in water, it will dissolve, leaving the desired object in great shape.

This article explores issues surrounding PVA, which remains a reliable 3D printing support filament. It serves as a resource to 3D printing enthusiasts keen on improving their print quality.

What Is PVA Filament?

Polyvinyl Alcohol (PVA) filament, a biodegradable polymer that remains sensitive to moisture, supports 3D printing material. Its chemical properties make it soluble, meaning it easily dissolves in water.

The fact that it’s a water-soluble material makes it a suitable support material for ensuring you get high-quality 3D print objects.

PVA is created in a chemical process that polymerizes vinyl acetate to form polyvinyl acetate. Then, you hydrolyze polyvinyl acetate to form the PVA filament.

Advantages of the PVA Filament

- Water-soluble support material

- Low toxicity

- It’s a colorless and odorless filament material

- No extra hardware needed for its application

Disadvantages of the PVA Filament

- Sensitive to moisture

- Use of airtight container needed

- Leaving printer nozzle hot when not extruding increases chances of clogging

- Costly

Best PVA Filament Brands

-

The eSun PVA Filaments

eSun PVA filament brand, manufactured in Shenzhen, China, remains one of the best PVA filament brands worldwide. Also, it comes in 500 grams spools and only in 1.75mm.

It’s an expensive filament brand though highly influential in the application.

Features

- Printer nozzle temp: between 190-220 degrees celsius

- Filament size: 500 grams

- Filament diameter: 1.75mm

- Colour: natural

-

PolyDissolve S1 Filament

PolyDissolve S1, manufactured in Shanghai, China, stands out as a famous filament brand in the 3D printing industry.

The brand offers a wide range of colors for you. PVA filament support structures make it possible for use as a support material for other plastics such as PVB, PLA, and PLA+.

It comes in 750 grams spools together with a weighing scale meant to help track the weight of filament left unused.

Features

- The temperature of nozzle: 215-225 degrees celsius

- Filament size: 750 grams

- Filament diameter: 1.75 to 2.85mm

- Color: natural

-

Ultimaker Filament

Ultimaker filament, manufactured in Holland, can be used in any FDM 3D printer that supports filaments with a diameter of 2.85mm.

Additionally, Ultimaker PVA brands work best with Nylon and CPE filaments. The manufacturers insist that it’s 100% biodegradable.

Comparatively, the Ultimaker filament proves to be the least moisture-sensitive among the brands.

Features

- Nozzle Temp:215-225 degrees celsius

- Filament Size: 350 and 750 grams

- Filament Diameter:2.85mm

- Color: Natural

-

GizmoDorks Filaments

GizmoDorks filaments manufactured in the US are designed to work as a support material for the PLA filament.

The brand offers the 500 grams filaments in two different diameter specifications. The filaments come in 1.75mm and 2.85mm diameters.

More importantly, the GizmoDork filaments degrade and easily clog at 200 degrees celsius. Also, when it blocks, you won’t be able to unclog it by adjusting the nozzle temperature like other filament brands.

Features

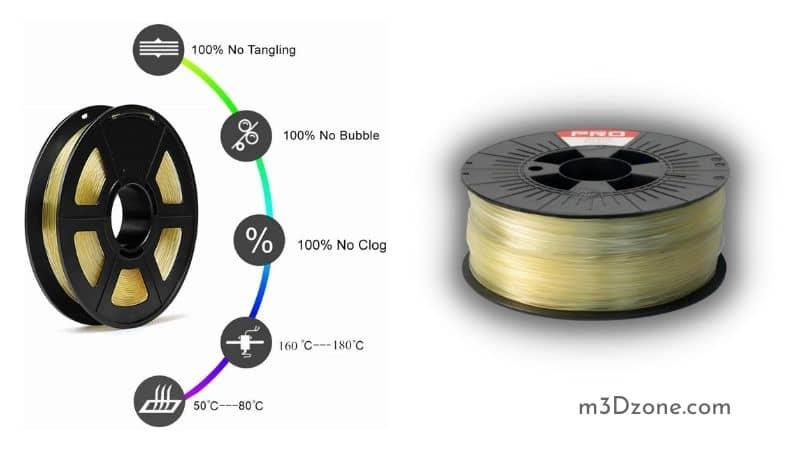

- Nozzle Temp:160-190 degrees celsius

- Filament Size: 500 grams

- Filament Diameter: 1.75mm-2.85mm

- Color: Natural

How Does PVA Filament Work?

PVA, being a water-soluble filament material, readily dissolves when put in water. Also, PVA supports 3D printing that uses PLA filament and not Nylon.

More importantly, PVA works well in a bed temperature of 45 to 60 degrees Celsius and should not be left to sit at temperatures of 200 degrees celsius. At 200 degrees celsius, PVA filaments degrade and cause irreversible jams.

What Is PVA Used for in 3D Printing?

PVA revolutionized the 3D printing process in a big way. PVA enables the printing of 3D models with a clear and almost perfect surface finish.

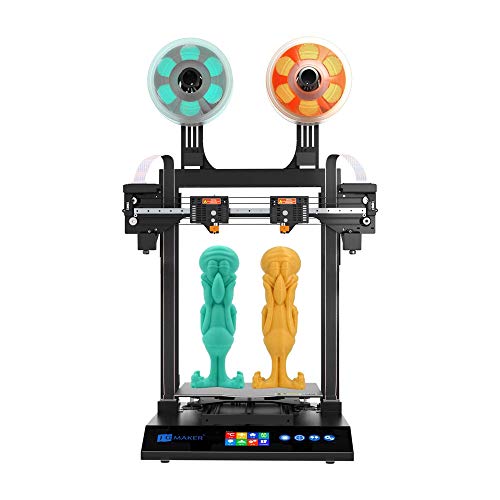

Additionally, PVA works to support other materials in 3D printing. To achieve the PVA support goal, you will need a dual extruder 3D printer.

Always use PVA filament with PLA plastic as they both print at a similar temperature making PVA a perfect support material for PLA.

The dissolvable qualities of the PVA make it helpful in supporting models with intricate details such as internal cavities and overhangs.

Furthermore, It can be challenging to reach the inside of the cavities or parts of the model overhangs. Thus, PVA filament support functions help as later, the PVA filaments completely dissolve in water and ooze shield. It leaves behind a model with a fantastic finish devoid of scars or damaged edges.

What Is the Difference Between PLA and PVA?

PVA remains a support filament material for 3Dprinting using PLA filament. However, as a PVA customer and a 3D printing hobbyist, you may still need to know the difference between the two filaments.

Attributes of PLA Filaments

- Starch-based filament (corn and plants)

- Environmental friendly filament

- Made from renewable resources

- Biodegrades if disposed of well

- Cheaper compared to ABS

Attributes of PVA Filaments

- A water-soluble plastic material

- Supports complex FDM 3D prints

- Works under low humidity

- Expensive as it costs twice as much as ABS

How to Dissolve PVA Filament? How Long Does It Take?

To dissolve PVA, you need to submerge the 3D printed object in the water, and it will start to dissolve slowly. To quicken up the dissolving process, you may use the following techniques;

a) Use Warm Water

Warm water slows down the PVA dissolving process time. Also, when using the PVA build materials, you need to use water that is less than 35 degrees celsius.

Otherwise, if you use hotter water than 35 degrees celsius, say 50 degrees celsius, it will affect the print quality adversely.

b) Stirring

You may use running water to dissolve PVA more quickly. You may dissolve PVA in under three hours. However, it will depend on the type of support material you use.

c) Use Pliers

You may opt to use your pliers (check at Amazon) to help you quicken the PVA dissolving time. First, place your 3D object in water for about 10 minutes. Then, take it out and use pliers to remove the bulk of the PVA support.

It would help if you remained extra cautious as you removed the PVA filament using pliers. You need to ensure you work slowly on it, do not touch or scrub the main 3D object.

After that, you may return the 3D object to the water so that only the remaining PVA support will need to dissolve.

Finally, it would help if you rinsed your object to get the final high-quality object.

PVA Filament Temperature

The optimal PVA filament temperature varies to the type of 3D printer in question. Also, the PVA filament temperature will vary between the types of filament brands available.

Generally, manufacturers page the PVA filament temperature at between 215 and 225 degrees celsius.

However, to get the optimal PVA filament temperature suitable for your printer, set your nozzle temperature precisely in the middle point of the manufacturer’s suggested temperature range settings.

For instance, for a range of 215-225 degrees celsius, start at 220 degrees celsius. Now, depending on the support structure quality, you may adjust your temperatures with a plus or minus 2 degrees celsius.

Is PVA Filament Expensive?

Yes, most PVA filament materials are expensive compared to the other 3D printer plastic filaments such as the PLA, ABS, TPU, and CPE.

The prices of the PVA filaments depend on the quality and the filament brand type. However, you may generally find good-quality PVA plastic filaments starting from at least $40.

Conclusion

To most 3D printing professionals and hobbyists, the discovery of the PVA filament proved a masterstroke in enhancing the final 3D print quality.

You may wonder what to do to achieve a perfect surface finish considering that some 3D objects have cavities inside that can not be easily reached.

The PVA filament comes as a support material that enables you to clear out these unreachable object areas.

After completing the 3D printing process, you only need to submerge the object in the water. The soluble properties of the PVA filament will allow it to dissolve, leaving behind a high-quality print object.

Recommended Reading

3D Printer Calibration. How to Calibrate 3D Printers

Does your 3D printer calibration affect the print quality of the finished print? Check out our easy guide on how to correctly calibrate your 3D printers...

Can You 3D Print Rubber? Is Rubber 3D Printing Possible?

Can you 3D print rubber? Yes. it is possible to create 3D print parts using rubber-like materials. Most rubber parts suit flexible production...

What Is a Resin 3D Printer?

So, what is a 3D resin printer? A resin 3D printer is a machine that uses light to convert models to prints. By directing UV light onto resins ...