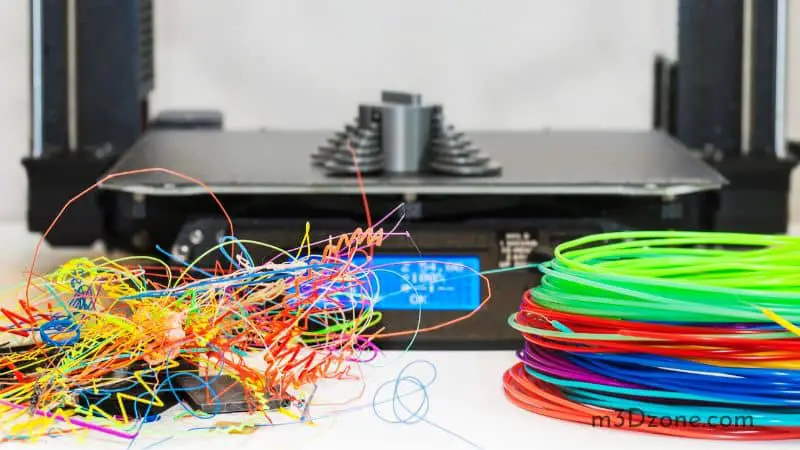

A knotted filament spool can be so annoying! Imagine the surprise of a tangled filament spool while you’re in the middle of printing. It can cause a print to fail if it happens often.

It occurs regardless of its size, but if you store the filament correctly, you need not fear untangling the whole spool to fix the problem.

We’ll discuss the causes of a knotted filament, how to untangle them, and how to prevent such problems.

Quick Navigation

Untangle 3D Printer Filament (Knotted Spool/Tangled Filament Spool)

You can untangle a 3D printer filament by unmounting the filament spool and bringing it close to the entrance of the feeder. Then, pull your slack back to create a bigger loop for the whole spools to pass.

You can resume printing by putting the filament spool back on the holder when everything is finally straight.

A filament can have knots quickly or, at times, take its time before it tangles in your printer. When it happens, it locks the spool preventing more filaments, and your printer becomes damaged beyond repair.

In all this, it may seem as if you’ve lost your printer, but I’m telling you you can save your printer.

You only have to pause your printer and unload and reload it. But the most recommended solution to this is to untangle filament as the printer is still printing.

First, you need to raise several turns and include the knot in the spool to get the tangled spool.

You have to raise it more times because if you do it a few times and can only see three paths from the tangle, you haven’t caught the knot yet.

Therefore more winding needs to be removed until you can only see one path from the spool. Rewind your spool filament under tension, and undo the tangle when you reach its peak.

Another way is to remove the spool and move it a little closer to the feeder entrance of the 3D printer, leaving some space to work.

You can pull the slack back through the knot and create just enough slack to pull the filament spools through.

Causes of Tangling Problem

Carelessness

The belief that cross-winding cannot cause knotting when you spool the filament is invalid. It’s impossible to spool filament vertically and cause it to wind.

If you don’t keep your filaments tightly wound and secure at the end of the filament, and you have a loose filament, the spool will unwind itself slightly.

The whole spool will push under another winding. In the end, you have a tangled spool. The bad thing about it is that you’ll not realize the tangled filament immediately.

Users in the years have talked about this, debating that the tangling must start with manufacturers. But to be honest, even if you are cautious about all this during printing, it is possible to still coil on its own.

Incorrect Storage

Leaving loose ends of the spool freely without securing them or not in your printer will cause them to tangle.

Proper storage will involve not leaving your filament spools with children, animals, or ignorant adults. Again store your filaments away from the sun as most are not UV resistant.

Exposure to the sun can cause damage over time.

Related: Storage solutions for 3D filament

Loose and Tight Spool Holders

Some filaments are stiff and may jump off your spool and wrap around the spool holders.

It will not cause a knot, of course, but when it entangles itself on the holder, the result will be an unmoving holder, which will stop providing materials at the hot end.

Damage can also happen from too tight spool holders that cause friction to the filaments, and in the end, they are unable to move freely, causing problems like poor adhesion clogs, not to mention jams.

Prevention

When you’ve opened your spool, the essential thing you first do is fasten the filament end. Check the guide holes on the spool while securing it with a universal filament clip or tape.

Most spool holders are tight or loose, and filaments may jump off the spool by themselves. To prevent this, you can use rubber bushing or something with less friction when spools spin faster.

Also, you can use a clip-on filament holder (filament clips) with arms to prevent the filament from getting over the top of your spool.

DIY Spool Filament Holder

How Do You Make a Filament Spool Holder?

There are many ways to make a filament spool holder for any sized spool, but today we’ll discuss the easiest and cheapest way you can make your own.

Requirements:

- a filament box

- a rod

- a pair of scissors

First, cut off the top of the box and then halfway down the box on one side. The filament vertically fits from the top, and the front should be able to let the filament through.

Second, on the side, have some slots to fit a rod that will hold up your spool. It should be a few inches down the box but not too low to avoid friction.

Your rod can be pencils, cardboard tubes, steel rods, PVC pipe, etc. Anything wide and long enough should work perfectly.

We advise you to use steel rods, and that will be all you need to make your perfect filament spool holder.

FAQ’s

How Do I Untangle My 3D Filament?

The moment you have found where the filament tangle is, push the coils on the surface until your knot is visible. Then, hold the knot and pull it out of the tangle.

Repeat this for all the knots and stop when you have untangled them.

How Do You Get a Stuck Filament Out of a 3D Printer?

You need to follow the guide from the manufacturer. Heat your extruder, then unload the filament on the printer. When it’s unloading, pull on the filaments.

Why Does My Filament Keep Getting Jammed?

It usually happens when your filament extruder cannot push the filament through the hot end, and in turn, the extruder grinds it until it’s too thin to reach the gear that advances it.

How Do You Rewind a Filament?

Mount both of your spools in a stable place. Then take a loose filament end of the initially spooled one and attach it to the center of the new spool.

Slowly spin the fresh spool for the filament to wrap on the entire spool, and don’t forget to untangle the new filament.

Wrap Up

We often find ourselves in deep problems of tangled spools because we ignore some tiny signs, and they end up causing us some significant impacts.

We hope that our article on how to untangle 3D printer filament has been helpful to you. Don’t let filament tangling be the reason why you’re not using your 3D printer. Happy printing!

Recommended Reading

How to Clean a 3D Printer Nozzle?

How to clean a 3D printer nozzle? Different ways: brushing the nozzle, then heat it and use a wire to remove the dirt. Or, you can soak the nozzle in acetone.

What Is SLA 3D Printing?

SLA 3D printing is a printing technique that uses the UV laser beam and prints one layer after another. The UV laser moves from one point to another producing..

How to Prevent PLA Warping. Useful Tips & FAQ’s.

Is PLA warping weighing down your 3D prints and destroying all the effort you put into? This post will help you identify the causes and how to overcome them.