Are you a 3D printing enthusiast seeking the highest level of print quality? Or could you be frustrated with poor finished 3D object surfaces?

Better still, are you looking for a technology that will guarantee you a faster printing speed? Look no further than the UV-curing 3D printing.

As an Amazon Associate, I earn from qualifying purchases. If you make a purchase after clicking on a link I may earn a small commission at no extra cost to you.

Stereolithography (SLA) is the earliest 3D printing technology that uses UV curing resin to create printed parts. UV 3D printing helps you achieve faster and better quality prints.

What Is UV 3D Printing Technology?

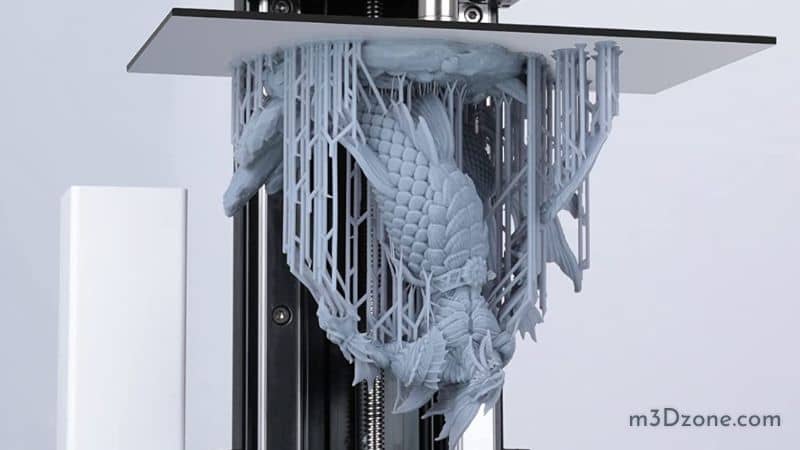

SLA printers use UV resin to create 3D printed parts. A galvanometer guides laser beams to hit the resin tank. Then the laser cures that part of the resin exposed to it.

Next, the elevator then raises the build platform by a layer. Thus, the light source cures the subsequent layer. The printer repeats the process until it completes printing the part.

Basic Guide

Stereolithography (SLA)

What Is SLA Technology?

Stereolithography is a 3D printing technology that uses computer pre-programmed CAD software to move laser beams. The UV light source helps cure the print part exposed to it.

Industrialists predominately use SLA printers to create concept models, complex prints with intricate geometry, and rapid prototyping.

What are the advantages of SLA 3D Printing?

- Stereolithography (SLA) 3D printing provides the following benefits;

- Quality surface finish

- Can print complex patterns with intricate geometries

- Best suited for miniatures

- Fast print time or short cure time

- Provides a wide selection of materials choice

- Compact design

What are the disadvantages of SLA 3D Printing?

- Not environmental friendly

- Post curing required

- The laser & transparent displays are fragile

How Does An SLA Printer Work?

An SLA 3D printer uses a high-powered laser to cure or harden the liquid resin. Such resins are contained in a resin tank. The quick curing process enabled by the UV light in the build plate helps create 3D objects with desired mechanical properties.

The SLA process or the resin 3D printing converts UV curing resin into solid 3D plastics. The conversion from resin to solid shape happens in a layer-by-layer fashion through photopolymerization.

Digital Light Processing (DLP)

Digital Light Processing (DLP) is a three-dimensional printing technology that printers manufacture photopolymer 3D prints. Notably, DL P remains quite similar to the SLA but retains a significant difference.

While SLA uses a laser beam to trace a layer to harden, DLP uses a projected source to cure an entire layer at once. Also, DLP 3Dprints parts or objects layer by layer.

Applications of DLP 3D Printing

DLP 3D prints incredibly intricate resin design items such as:

- Jewelry

- Toys

- Molds

- Figurines

- Items with fine details

Advantages of DLP 3D Printing

- High laying accuracy levels

- Short print time due to high print speed

- Wide range of application areas

- Lower printer costs

Disadvantages of DLP 3D Printing

- Post-processing needed

- Liquid resin is wet, sticky, and hazardous

- Resin has a distinct unpleasant chemical smell

- High costs

- Insecurity of consumable materials

What is LCD/MSLA in 3D Printing?

- LCD stands for Liquid Crystal Display. In the 3D printing circles, you can call it Masked Stereolithography (SLA). It is one of the three resin 3D printing or Vat polymerization technologies.

- LCD screen works by using a light source to project layer-by-layer print images on the build platform to create a 3D printed part.

Applications of LCD/MSLA 3D Printing

- Dental

- Jewelry

- Engineering

Advantages of LCD/MSLA 3D Printing

- Use cheap resin

- Inexpensive machines

- Higher accuracy levels

- Excellent equipment craft

- WiFi module enables machine print wireless or offline

- Fine details

- Smooth surface

- Fast speed

- Support won’t damage the surface much

Disadvantages of LCD/MSLA 3D Printing

- Small building volume

- Post-processing is a must

- Curing continues past printing

What is Material Jetting in 3D Printing?

- Material jetting is an inkjet printing process that uses the printer head to deposit liquid UV resin material onto the build plate layer by layer to create 3D models. Additionally, it uses UV light to harden the material, thus solidifying them to create 3D models.

- More importantly, material jetting combines the excellent details of resin 3D printing with the exceptional speed of FDM printers to create parts and prototypes.

- It is important to note that there are no material jetting printers for hobbyists. Only industrial material jetting printers are available for professionals in different industries.

Applications of Material Jetting in 3D Printing

- Biocompatible dental molds

- Rapid factory tooling

- Rapid industrial prototyping

- Manufacturing industrial jigs and fixtures

- Medical anatomical models

- Jewelry

- Artistic purposes

Advantages of Material Jetting in 3D Printing

- Printed on multi-material

- Print multi-color

Disadvantages of Material Jetting in 3D Printing

- Small build volume

- Requires print media

- Requires post-processing

Best 3D Printer UV Resin

You use plastic filament in 3D printing, such as FDM printing. Likewise, you use liquid resin in resin 3D printing to create printed models.

Liquid resin is a mixture of various chemicals and additives that determine the mechanical and chemical properties of the resin.

So, just as the plastic filament quality determines 3D print quality in FDM processes, liquid resin quality fully accounts for the final object print quality in resin 3D printing.

Here is a list of some of the best three printer UV resins:

-

Siraya Tech Fast

Siraya Tech Company produces the Siraya tech liquid resin. The Siraya tech brand of resin remains one of the best resins you can find for your resin 3D printing.

It smoothens out any layer lines that may appear on the printed part. Also, it is perfect for creating hallow prints. The resin allows the printed object to strengthen without turning brittle.

More importantly, it provides the advantage of printing and curing faster.

-

Anycubic Plant-Based Resin

The Anycubic plant-based resin is a popular resin that has a lower odor. Additionally, it doesn’t get as thick when subjected to cooler temperatures as with standard resin.

More fundamentally, it is an affordable liquid resin good enough for most applications. It is easy to print with and offers beautiful model clarity.

-

Phrozen Onyx Rigid Pro 410

It is used for producing objects with minute details. Also, it is rigid but not brittle.

Phrozen Onyx Rigid Pro 410 is a tough and durable resin with great flexibility. The flexibility enables it to achieve dimensional stability. Thus, it is suitable for drops in the tiles as they can’t easily shatter into pieces upon such drops.

FAQ

What Is a UV 3D Printer?

A UV 3D printer is a printing technology that uses liquid resin and light to produce solid 3D printed parts.

How Does the UV 3D Printer Work?

It uses a UV laser light that applies the object’s shape to the surface of a photopolymer tank. The resin solidifies to form a 3D print. This process is done repeatedly until the whole 3D model is complete.

Do 3D Printers Use UV Light?

Yes! Digital Lighting Processing (DLP) 3D printers use UV light to print 3D models. The 3D model is sent to the printer using CAD software.

The printer projects the model image onto the Vat of the liquid. The liquid solidifies where the light hits, and the object is cured layer by layer, forming a 3d printed part.

What Is 3D Printing in UV Resin?

It is a 3D printing technology in which liquid resin is stored in a container. The print resin is not injected through the nozzle, as with filament3D printing.

A UV light source then hits the part of the resin exposed to it, resulting in the hardening of that layer. The process is repeated layer upon layer until the 3D model actualizes.

Conclusion

Resin 3D printing has improved the 3D print quality in a big way. Professionals and enthusiasts embraced it for its fast printing speed, wide range of application areas, and lower printing costs.

Significantly, you’ll find numerous resin types in the market for your resin 3D printing. The choice depends on your individual print needs.

Recommended Reading

HIPS Filament vs PLA, PETG, ABS

In this article we take a closer look at HIPS filament vs PLA, PETG, ABS. HIPS filament provides one most effective soluble support materials and affordable.

How to Dry PETG Filament?

How to dry PETG? To dry your PETG plastic filament, you need to put it in a convection oven or a dehydrator. Follow the instructions in this article.

Top 8 Best 3D Printer Software for Mac Users (FREE Included)

You like 3D printing and have a Mac. What 3D printer software for Mac do you use? Let us guide you and show our top 8 picks. Some are free some not.