Some 3D printer problems are easy to detect as they happen right before our eyes, but some issues build up undetected until they create so much damage.

Such issues may cause significant damage to your 3D printer before you notice, such as blocking the nozzle.

Quick Navigation

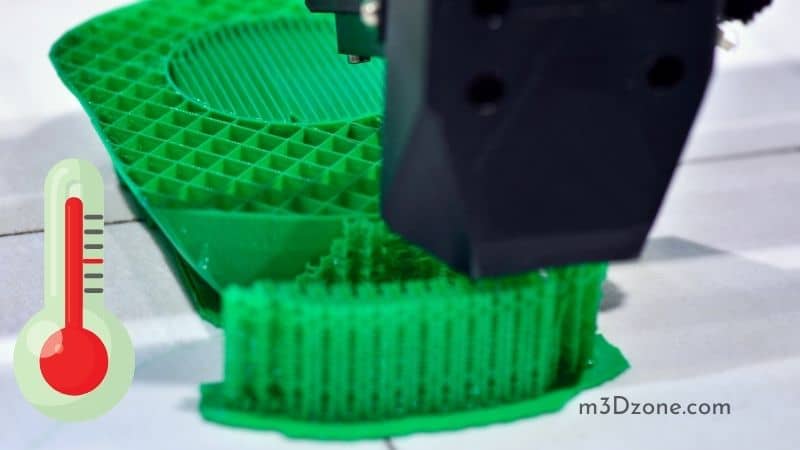

A good example is the heat creep in the 3D printer.

A heat creep is not easy to detect until they create much damage, which is irreversible.

In the 3D printer, there is a heater cartridge affixed to the heater block. When the heater cartridge heats up, the heater block also heats up before the heat disperses out.

It goes through the thermal barrier tube, melting the filament in the process. The filament expands as it moves through the tube and melts in the heater block.

The molten filament is then ejected from the nozzle end. On cooling the extruder, the heat in the thermal barrier tube rises.

When the heat creeps in the tube, the filament within swells almost immediately. The Polylactic Acid (PLA) sticks on the walls causing a thermal barrier.

It helps to have some tips to help you prevent such troubles, and this article highlights some of them.

What Is Heat Creep?

What exactly is heat creep? It sounds like a foreign concept until you know the hot assembly composition of the 3D printer and how these parts work and coordinate with each other.

To set off, the hot end is where the filament melts before being ejected from the nozzle. It is found next to the extruder assembly.

The heating block is found above the nozzle and is the region that produces heat to melt the filament. Next to it is the temperature sensor. It detects the filament temperature and determines the amount of power directed to the heating block.

The next part is the heat sink. It’s found between the heating block and the extruder assembly, thus separating them. Some of its properties are electrical conductivity and the integration of a cooling fan.

The heat sink is responsible for driving excess heat from the filament to the exterior environment. Excess heat can damage components of the extruder assembly if not driven off.

A heat creep occurs when heat produced at the heating block travels upward so that the filament melts in excess out of intended bounds. As a result, the filament swells rapidly, which can result in extrusion issues.

What Causes Heat Creep 3D Printing?

Heat creeps in 3D printers can happen anytime, without your knowledge. One of the essential things you need to know if you could fix this issue is probably what causes the heat creep.

There are several causes to this trouble, mainly arising from the hot end of the nozzle, the nature of filament heating, and the PTFE lining.

These issues should be addressed urgently because they can lead to heat creep within no time, lowering the quality of your printouts.

Here are some of the most common causes:

-

Too Hot

High temperatures in the heat block cause the excess heat to escape to undesired parts within the 3D printer, causing heat creep.

-

Hot End Design

Different hot ends have different capacities to withstand heat. A hot end made of metal tends to allow heat to move quickly within the hot end assembly if other factors cause too much heat build-up.

-

Filament Staying at the Hot End for a Prolonged Period

When the filament is left at the hot end for a longer time, it melts before reaching the melt zone. This leads to a heat creep in the 3D printer.

-

Malfunctioning Hot End Cooling Fan

The hot end fan is supposed to cool and drive excess heat from the hot end and the heat sink assemblies.

A malfunctioning fan will be insufficient in driving off the excess heat generated at the heat block. The heat will thus move the hot end upwards, causing the filament to melt before reaching the melt zone.

Heat creep can also result from other factors within the 3D printer, such as printing at a very low printing speed, having a dusty heat sink, and high retraction length.

Tips to Help You Address Your 3D Printer Heat Creep Issues

Dealing with heat creep issues in a 3D printer is not only about fixing the problems at hand; you’re also supposed to be well-versed with tricks on avoiding or preventing these issues in the future.

The first step is to identify the problem and the source of the problem. You’ll want to confirm if the issue is heat creep, if not any other.

Ensure to match the PTFE tube with the nozzle. If you suspect the problem might be with the nozzle, replace it. If the problem you’re having doesn’t go away, then the issue is heat creep.

Here are some tips to help you when dealing with heat creep:

- Adjust the 3D printer settings one by one. Going through the settings one after another makes it easy to identify the exact problem and where it is coming from. Avoid configuring multiple hardware or slicer settings at ago.

- Lower your retraction settings. The retraction settings determine the filament amount ejected out from the nozzle when the printhead moves. High retraction length causes the hot filament to move past the melt zone, causing heat to transmit through the assembly. Lower the retraction settings if that is the issue.

- Cut the PTFE tube ending more often. This practice ensures the Teflon tube ending remains unburnt to ensure a perfect fit between the nozzle and the PTFE tube. This will help prevent heat creep from occurring.

- Clean the hot end assembly. Always ensure the hot assembly is dirt and dust-free. Clean the hot end after every few prints. Particles in the hot end assembly not only result in heat creep but also cause other issues. When cleaning, use a damp clean your hot end assembly, use a damp or a rubbing alcohol cloth piece to clean both the interior and the exterior of the hot end components while they are at normal printing temperature. However, when cleaning the nozzle, use a nozzle needle to remove particles from it.

- Your filament should be of high quality. A high-quality filament with a tolerance of at least below +/- 0.05 mm has a consistent diameter and prevents the hot end from jamming.

- Use a PTFE tube of good quality. The PTFE tube is supposed to insulate the filament inside the tube. A high-quality PTFE tube will adequately protect the filament in place. The PTFE tube should also be of good temperature resistance.

- Always shut down your 3D printer after printing. Turning off the printer ensures the hot end assembly cools down after finishing printing. But before you shut down the Printer, make sure the hot end stops heating first.

- Clean the hot end fan: Dirt particles in the fan can lower its speed, reducing its cooling efficiency. Clean the fan regularly with a rubbing alcohol cloth.

- Remove filament when you finish printing. Failing to remove the filament from the hot end causes it to melt above the melt zone. So, we recommend you remove them after you’re done printing.

How to Fix Heat Creep in Your 3D Printer

Reduce the Printing Temperature

High print temperatures from too much heat from the heat bed cause heat creep in the 3D printer. To lower the temperature, change the filament settings or the slicer.

Keep the temperature just high enough to melt the filament.

Increase Fan Speed

If you have a cooling fan at the hot end, you need to increase its speed, but consider installing it around the heat sink if you don’t have one.

The fan speed should be enough to cool the filament to ensure it only melts at the melt zone. Have the fan at 100% speed to eliminate the heat creep, then lower the speed to a convenient level.

Some of the fans you should consider are Noctua and CUI devices fans, but Noctua is the best bet if you want a silent fan.

Replace the Heat Block End

All-metal hot ends encourage heat creep build-up if there is excess heat production. The metal can also conduct heat through it.

You may need to replace this hot end with a PTFE-lined hot end to eliminate the heat creep.

A PTFE-lined hot end has a removable PTFE tube that provides better insulation to the filament. The tube also maintains the temperature at which the filament melts until when the filament reaches the melt zone.

Provided your 3D printer print settings are correct, high-quality hot ends should not give rise to heat creep issues.

Increase Printing Speed

The filament at the nozzle does travel at high speed. As far as this is concerned, having your 3D printer printing at a lower speed can be inconsistent between the ejected filament and the filament within the extrusion system. This imbalance can give rise to heat creep.

Increase the printer’s printing speed to help have a consistent filament flow. Be sure to check if the printing speed is correctly calibrated as incorrect print speed can result in issues to the 3D printer.

A speed tower is an excellent solution to calibrating the printing speed. It allows you to calibrate different printing speeds on a similar print to determine the speed effect on the print quality.

Final Thought

A heat creep in your 3D printer is one of the most challenging problems you will likely encounter when 3D printing. The problem is not easy to detect until it creates more irreversible severe issues.

Always check the hot end assembly and address any detected issue immediately before it causes more significant damage.

The heat creep issue is mainly associated with high printing temperatures. Be sure to follow the tips we’ve highlighted in this article to help prevent heat creep from occurring.

Recommended Reading

What Is a Good 3D Printing Speed?

For slow 3D printers, use 40mm per second to 80mm per second 3D printing speeds. Mid-speed printers work best with 100 mm/s. Fast-speed 3D printers use 150mm/s.

What Is PCTG Filament? Is It Better Than PETG?

What is PCTG filament? And why is it believed to be a fine filament to most of the famous 3D printing filaments, PETG included?

How Long Do PLA Prints Last?

How long do PLA prints last? PLA material lasts a while under normal circumstances. Yes, PLA 3D printed objects degrade over time, just like any other machine.