Have you tried printing a 3D print but every time you are halfway your printer stops? Experiences like this one frustrate people to the extent of thinking their 3D printers have serious problems.

The problem may be serious to some extent, but once you figure out the issue, fixing it will be easy.

Your 3D printer stops mid-print for several reasons, including overheating, insufficient printing filament, or clogged nozzles.

At other times, your printer may be using broken filament, inappropriate retraction settings. In the case of overheating problems, have an additional cooling fan to facilitate easier cooling.

Quick Navigation

Read through this article to find out why your 3D printer stops extruding mid-print. You will also learn how to fix each problem.

Why Does My 3D Printer Stop Printing Mid-page?

Why does your 3D printer stop whenever you are in the middle of a 3D printing project? Here are the issues to look out for.

-

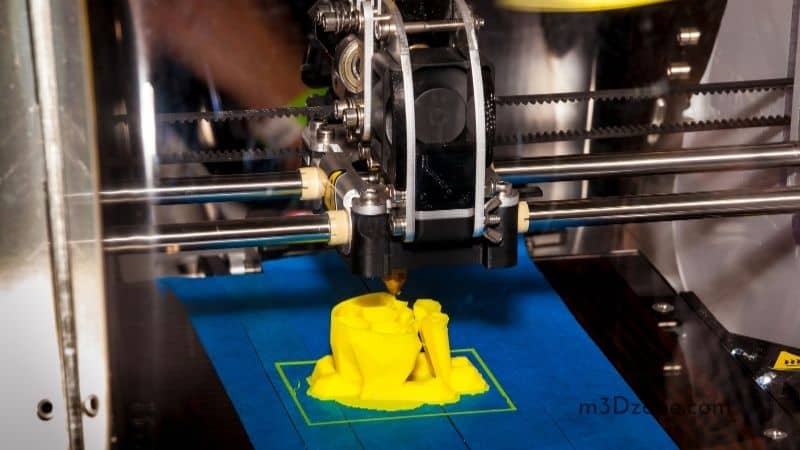

Printing Filament in Bad Conditions

The first thing you should do when your printer stops extruding before you complete a 3D print is to check your filament condition.

When you store or handle the material used for printing inappropriately, it will break. Mishandling also affects some filament properties, which weaken it making it unfit for use in 3D printers.

If you now use these compromised filaments, you may experience problems while printing, including your printer stopping mid-print.

Ensure you check the spool you are using for any breakages. It would be best if you also tried to pull the filament in your printer through its nozzle. If it comes off through the end easily, then it is loose, which could be the problem. Remove the entire loaded bunch and replace it with fresh filament before beginning another 3D print-making project.

If you don’t want to face issues related to mishandling of filament, ensure you store the box with your filaments appropriately. Be sure to double-check the filament you are getting from your vendor since, at times, you may buy compromised materials.

Provide an environment with controlled light and humidity conditions. It would help if you also regulated the amount of heat your filament is being exposed to. If the heat is too much, your filament will break easily if slightly mishandled.

-

Insufficient 3D Printing Filament

3D printing consumes more filament than most people expect. Whenever your print speed is high, you will extrude more filament. If you continually extrude high volumes of filament, you will need to refill frequently.

Before you conclude that your 3D printer is stopping mid-print because of low filament levels, first double-check.

If you find that the printing material is low, buy a new filament spool and load it into your printer. Now restart the printer and carry on with your 3D printing using a fresh spool.

-

How to Avoid Running Out of Filament in the Middle of Printing

To avoid insufficient filament issues arising in the future, turn on indicators in your 3D printing software. These indicators will alert you when the content is low, giving you a chance to add enough filament.

You should also make sure your extrusion is not way too much. Excessive extrusion often results in a bigger layer height than needed. When you have an appropriate extrusion, you will save filament, allowing you to finish a 3D print without running low on the filament.

Something else you can do to avoid such issues is investing in a modern slicer. Most of these slicers display the projected material needed to complete your project. If you dint have enough material, it would be best to buy a new spool and load it into your printer.

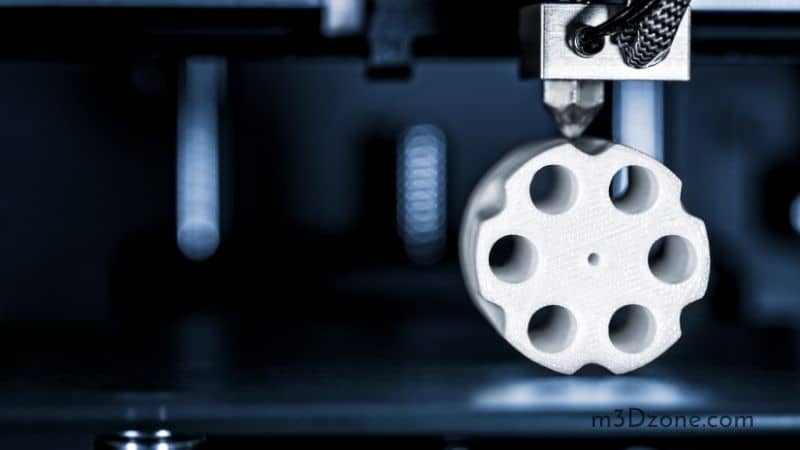

Clogged 3D Printer Nozzle

People who print numerous 3D prints often switch between different types of filaments. If you are one of these people, then your 3D printer may stop mid-print.

Switching between filament types is not wrong. However, you need to ensure you clean your 3D printer nozzle before using a different filament type.

Allow me to explain. If you are loading filament into your 3D printer manually, some pieces will get stuck. Similarly, pulling material from the printer is likely to leave some pieces stuck. A problem will arise when these pieces increase, causing a jam.

Whenever you experience clogged nozzle issues often, it would be best to reduce the retraction settings. Also, reduce your print speed settings. If the problem persists, add more heat by raising the temperature, which melts the clogging filaments.

-

How Do You Unclog a 3D Printer Nozzle?

The good news is, your printer is not broken. Be warned, however, that you need to be careful when unclogging the nozzle to avoid damaging it. Therefore, the question becomes, how will you safely remove the clog from the printer’s nozzle?

The first way of unclogging a 3D printer nozzle is by using a needle. A pin works, too, as long as you handle it with care.

Here, you must first ensure there is enough heat to melt the clog. You, therefore, must heat the nozzle to the filament’s printing temperature. Remember, PLA filament and other filaments have different melting points. This demands that you set the temperatures according to the specific filament you use.

The next step involves you holding the hot nozzle with an appropriate tool. If you touch the hot nozzle without protection, you will get burnt. Finally, dip the needle or pin through the nozzle. Twist it around to facilitate faster removal of the clog blocking the nozzle.

The other most common solution to a clogged 3D printer nozzle is cold or automatic pulling. In this method, you are required to take apart the hot part in your 3D printer to give you a more clear sight of the nozzle’s interior.

-

How Do I Prevent My 3D Printer Nozzle From Clogging?

Dust particles sometimes land on the inner side of your 3D printer nozzle. When combined with other unwanted things such as broken filament, a clog will form, stopping your 3D printer from creating a print mid-page. The most effective way of keeping these materials off your printer is proper maintenance.

Frequently switching between filaments will become an issue if you don’t regularly clean your printer’s nozzle. Using a brush, a needle, or cold pulling will do the trick.

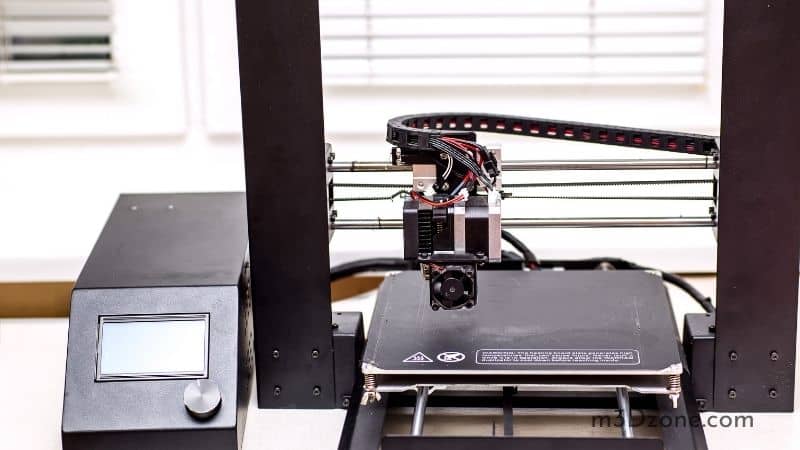

Overheating

Overheating is one of the most overlooked issues by most 3D printer users. When the temperature is too high, your 3D printer will stop before you are done making 3D prints.

Some manufacturers have realized this issue and have reacted by adding a thermal cutoff to this printing device. Whenever your printing device is beginning to overheat, the thermal cutoff will shut it down.

If you suspect that your printer has stopped mid-print due to overheating, check it out. One of the things you will do is unplug it from the power supply. You will then carefully touch the extruder to see if it’s excessively hot.

If the extruder is too hot, power it off for a while to give it enough time to cool down. Using a cooling fan hastens the cooling process, which helps you get back to your project quicker.

How Do I Increase My 3D Printer Tolerance?

When your 3D printer stops extruding mid-print often, it may eventually stop working completely. Your first response to this issue should be checking for loose wire connections. If you are not sure how the wire should be connected, do a menu search or contact the manufacturer.

Something else you can do to increase your 3D printer’s tolerance is to develop simple designs. When you are creating a too complicated print, your printing device may stop before you are done. Therefore, be sure to keep designs simple if you are not making prints that must have a complex design.

Another way to of increasing your printer’s tolerance is by adding a feature that facilitates faster cooling. The best feature for this job is a cooling fan. When the temperature gets dangerously high, a cooling fan will cool the printer preventing further damage.

When the temperatures are too high, the heat will melt your filament above the heatsink. Consequently, a clog will be formed in the extruder. Here is how you resolve this issue.

- First, open the extruder body enclosure to give you an unblocked view of the interior. Now adhere one generic heatsink to the printer’s extruder motor. For this step, you will need epoxy or any other adhesive that is thermally conductive.

- The second step is installing a fan that will be cooling the extruder motor. If this does not solve your issue, upgrade the extruder motor to moons motor. You are also free to upgrade the motor drivers.

Wrong Print Bed Distance

When the bed is too close or too far from the extruder, then the print will miss the first layer, or the filament may not stick to the bed when you are creating a model.

All 3D printers use stepper extruder motors on their axis positioning. At this point, they accurately place the print head together with the build surface. On the other hand, they meter the filament at its extrude to the hot end.

The stepper extruder motor controls the speed and accurately controls the axis by stepping and not seeing the naked eyes as rotating. It makes a repeated movement with fixed increments, which makes it seem like the motor is rotating.

The motor determines the step’s size, and the power of the steps is from the stepper extruder motor driver. To ensure your printer works and steps efficiently, you need to ensure that the stepper extruder motor driver is working in optimum conditions.

There are two different ways in which you can troubleshoot the problem or prevent it. Go to your setting and control the Z-axis on the setting. By doing so, you offset the Z-axis to a positive value or even a negative value.

Whether positive or negative will be determined by raising the nozzle higher and away from the bed. That way, you help the print to stick on the bed and respectively.

Conclusion

There are multiple reasons why your Prusa or any other printers may stop mid-print. An error will occur if there is a loose wire connection as a result of overheating.

One of the ways to monitor your printing progress is through Octoprint. You can even do a test print to know your progress, which will help you determine whether there is a need to add more filaments.

Recommended Reading

3D Printer Maintenance. The Ultimate Checklist!

3D printer maintenance services ensure that the printer runs well and performs as intended. No more failed prints and enhance the 3D prints quality.

Why Is It Important to Have a Filament Runout Sensor?

The problem is a lot of printers do not recognize when filament runs out. This is where the filament runout sensor comes into play. Let's find out more!

SLS vs FDM 3D Printing Comparison. Which to Choose & Why?

SLS vs FDM 3d printing comparison. FDM uses the extruder hot end to deposit layer by layer while SLS uses a laser beam to heat powdered nylon. See more!