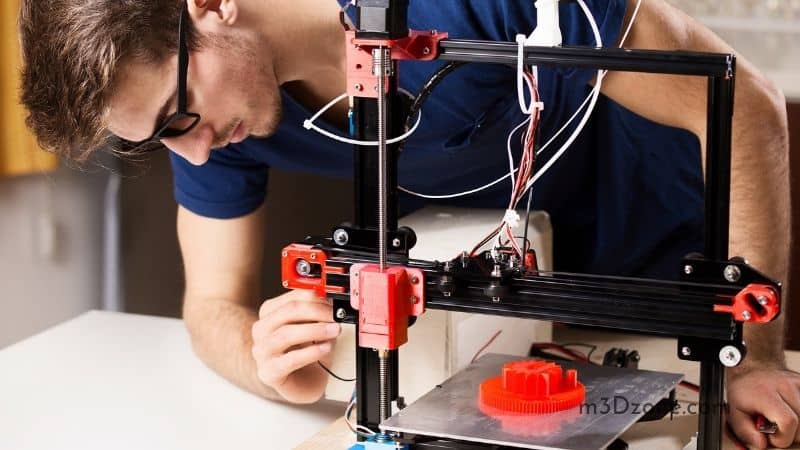

A 3D printer that is not cooperating can be frustrating. The problems can range from a messed thermoplastic to having a complex extruder assembly or simple issues like a dirty nozzle.

As an Amazon Associate, I earn from qualifying purchases. If you make a purchase after clicking on a link I may earn a small commission at no extra cost to you.

There are different ways of cleaning a 3D printer nozzle. You start by brushing the nozzle, then heat it and use a wire to remove the stuck dirt. Alternatively, you can soak the nozzle in acetone to help in the cleaning process. All you need is to ensure you follow the guideline to ensure you clean it well.

Quick Navigation

When operating a 3D printer, you must learn how to clean the nozzle, as it should be done often if you want it to work efficiently. In this article, you will learn easy ways to clean a nozzle to make your work easy.

How Do You Clean a 3D Nozzle?

The method you choose to clean the 3D nozzle depends on the severity of the dirt. Below are tips for cleaning a 3D printer nozzle.

-

Start by Brushing the Outside of the Nozzle

The first step is brushing the outside of the clogged nozzle as it will help remove the residue that is stuck from the outside. Ensure you use the right brush, which in this case, a wire brush is the best for the job. It will remove the stubborn residues from the melted material. Use a brass wire brush with the brass thread. The brass wire brush is to prevent the nozzle from tearing or getting damaged.

If all the blockings get out, then you don’t need to go to another step, as the aim was to remove the clogs on the nozzles.

But it’s good to note this method only cleans the nozzle end. For that reason, it may not solve the clogging problem. And this is where you go to the next step.

-

3D Printer Nozzle Cleaning With a Pin

If the clog is not badly built up, you need to remove the melted filament using a pin. Also, a small needle can do the work. Start by heating the nozzle to a point where the nozzle softens but not to the melting temperatures.

Use a heating gun to manage the temperature, or you can use a hot end assembly. After that, push the soft materials out of the nozzle using the pin or needle’s tip. An alternative is using an acupuncture needle to remove the ABS filament build-up from the printer head.

How Do You Unclog a 3D Printer Nozzle?

The 3D printer nozzle cleaning method you use to unclog the nozzle depends on the amount of clog on the nozzle. If the clog is a small amount, then you can clean it up with a probe.

Use a thin wire but avoid scratching the nozzle’s inner part as it will interfere with how it functions.

A guitar string is perfect for that work as it’s rigid, and hence it won’t scratch the inner part. If you are looking for a durable material to unclog the nozzle, then a brass wire is perfect, but you need to be careful when using it.

How to Clean a Blocked 3D Printer Extruder Nozzle

Start by unloading the filament. Look for the “unload” option on the printer menu, select the option and wait for it to heat up before removing the filaments. After that, pull out the filament slowly to avoid any damage.

Then, soak the nozzle in acetone for around 15 minutes and ensure all parts of the nozzle are fully submerged in it. Use a soft cloth to clean and dry the nozzle after 15 minutes. A paper towel can as well be used.

Acetone is a product used in removing nail polish and is available in the drugstore. It helps to loosen the filaments, and that way, they break down and come out.

At this point, use a heat gun to heat the nozzle for around one minute. The gun should be pointing straight up as it heats. Also, use a plier to hold the nozzle above the heating element.

The nozzle should heat up completely, so keep turning it around so it can heat evenly. This process will help the remaining filaments to loosen and come out.

Use a needle or a pin to push the clog out of the nozzle. Holding the nozzle tight with the pliers, poke the needle or pin into the nozzle. Clean the side by scraping the side to remove all the residue.

After cleaning, put in a fresh new filament. Do so by pressing and holding the extruder option. When you do so, the command pushes the fresh filament, which in return pushes the unwanted melted materials that are clogged on the nozzle.

Always ensure you use the type of filament in your nozzle. An example, if you use ABS filaments, don’t replace the filament with the PLA filaments when cleaning.

How Do I Know if My Printer Nozzle Is Clogged?

The first way to know your printer is clogged is when the prints are low quality as they are faded and have lines in them. Also, you can get a blank page when you print. Apart from that, white lines running across the page are also a sign of a clogged nozzle.

When you notice broken lines on your print or a grid pattern, then it is a sign that your 3D nozzle is clogged, and you should clean it.

When there is some missing color on the print and some track marks, smear marks are signs of a clogged tip that needs cleaning.

The other signs of a clogged tip are when the filaments don’t exclude uniformly. Apart from that, when you notice the tip is excluding extremely thin filaments, or nothing is coming out of the nozzle.

How Often Should You Clean Your 3D Printer Nozzle?

Cloggs on extruders and nozzles are caused when there are leftovers of filament which get stuck after changing the filament. For this reason, you should clean up the tip every time you switch the filament.

As it’s hard to remove all the materials on the tip after removing the filament, you can change the filament. To avoid blocking the nozzle, always make sure you clean the leftover. You can do so by pushing the materials using more filament.

When there is dirt or dust on the filament, it burns on the nozzle’s hot end, and with time, the burnt materials will accumulate and clog the tip. For that reason, you need to ensure the filament is always clean.

When purchasing filament from the manufacturer, it is clean, and you can use them directly. But to maintain them in a clean state, you need to store them in an air-tight bag. The best place to store the filament is in a vacuum bag together with packets of the desiccant.

You might like: How do you lower electricity costs for your 3D printer?

Easy Ways to Clean Your 3D Printer Extruder Nozzle

-

Buy Cleaning Filament

One of the things people do to solve dust particles and other unwanted material or products problem is buying cleaning filament. Through your browser look for a site that sells cleaning filament at a fair price. Technology has made life easy as one can access information and people can now compare the prices of cleaning filament easily.

Cleaning a 3D printer extruder nozzle clogging is at times uncomplicated unless there are major melted materials stuck inside. And even then, you can still unclog and clean the tip all by yourself.

Clean the 3D printer nozzles by heating the leftover filament to its melting point. Once it is past the printing temperatures, it pushes it through to push the blockage out. The filament will come out smoothly, but if it doesn’t, do not force it; try another method.

-

Use the Nozzle Unclogger

If the above methods don’t work, then try using the nozzle unclogger, which in most cases comes with your printer in the nozzle cleaning kit. A nozzle clogger is a small wire inserted in a heated tip to remove the melted materials.

All you need is once you insert the wire, you wiggle it all around and then push the wire as fast as you can to remove all the materials causing the blockage.

At this point, if the unclogger works, the filaments can not extrude easily after you remove the wire.

-

Use a Heating Gun

But if it is still not working, heat the nozzle using a blow dryer or a heat gun. Be keen when using a heat gun as it can overheat the metal and cause it to wrap.

After heating the 3D printer’s tip, don’t touch it as you will get burnt. Allow it to cool first.

At this point, the clogging material is melted, and the nozzle should be unblocked and clean.

-

Cold Pulling Method

If the above methods don’t work, then insert the nozzle’s filaments by using your hands. The method is known as cold pulling. Heat the 3D printer’s tip for around 250 °C.

Leave it for around five minutes cooling it down back to its room temperature. Once the nozzle heat has reduced, you can go with nylon or ABS to solve the clogging problem through the cold pulling method.

Push the filament into the tip using your bare hands. The filament will be heated to its melting temperature.

The clogged material will also melt and flow through the extruder together with the nylon filament or any other filament that may have been on the build platform.

After a few minutes, heat the 3D printer’s tip again, but this time around 130 °C, it softens the filament instead of melting it. To finally solve the clogging problem, pull out the unwanted PLA or ABS filaments from the end.

What Do You Do in Case of the Filament Is Stripped Away?

When pressure builds up in the nozzle, it can cause the filament to get stripped away, caused by the hob of the extruder. This causes two problems now, a clogged nozzle and an extruder gear.

When this happens, pull out the filament to see where the filament has been ground away.

Solve the issue by cleaning the hob of the extruded as, in most cases, they are filled with plastic. If they are not cleaned, they don’t grab the filament and can’t extrude them at the right printing speed.

To access the hob gear, you will need to disassemble the extruder assembly. Before disassembling it, you need to ensure you know how to return it in the right way to avoid causing more problems. Also, it’s good to note once you disassemble the extruder, your warranty becomes invalid.

Decide if the whole disassembling is needed. To clean the hob, if you decide to disassemble, all you need is a small pointed tool and put it in to remove the plastic materials. Even the regular toothpick will clean the hob efficiently.

Conclusion

Every material or machine that is used regularly needs maintenance to serve you in the right way. For a 3D printer, cleaning the nozzle regularly will save you from getting a blockage that can stop or affect your work quality.

Utilize the information in this article to boost your 3D printer nozzle cleaning skills. When cleaning, ensure you use the right tool and follow the right guidelines to avoid causing more harm to the printer and affect the quality it produces.

Recommended Reading

Casting vs 3D Printing. What to Choose?

Casting vs 3D printing. 3D metal printing gives you full control over the casting process, which is not the case with traditional metal casting.

PVA Filament. What Is It and What Is It Used For?

PVA filament is a biodegradable polymer that remains sensitive to moisture. Comes as a support material and its chemical properties make it soluble.

3D Print Stringing. 5 Easy Ways to Fix It & Prevent It!

So, what is 3d print stringing? Stringing occurs when filaments leak through your 3D printer nozzle in places where they shouldn't. Fixing stringing is easy.