A 3D printer operator is a competent individual with technical and creative skills in additive manufacturing. They use computer-aided (CAD) software to develop designs to be 3D printed into finished works.

Quick Navigation

Did you know there are way more career opportunities as a 3D printer operator than you might realize? How about 35% of all the jobs posted for engineering in September 2014 require 3D printing and additive manufacturing industry skills?

And these numbers keep steadily rising because it’s an area people are still sleeping on.

How Do I Become a 3D Printer Technician?

3D printing involves using CAD software to develop objects in layers. So, as part of the team manufacturing products, one of your primary responsibilities will be creating the daily routine for the 3D printers.

You’ll examine customers’ designs to determine if they can get 3D printed. You may also provide input on how to make the process smooth. Other activities may be performing post-processing tasks like sandblasting or polishing and working with production personnel to introduce new job processes.

Being a 3D printing technician, you may also aid in maintenance activities like repairing and cleaning the machines. You may also collaborate with your product management team to develop the product, including updating the design processes.

Required Education

You’ll typically require a bachelor’s degree. Employers look for a degree in engineering, computer science, software development, and fine arts. Some level of experience in production or manufacturing is a bonus.

College courses in relevant fields like creative design and model making are also eligible.

Required Skills

High mechanical ability is a vital skill if you want to be a 3D printing technician. You should understand how all 3D printer parts work, be knowledgeable in 3D modeling, coding, materials science, and more. You should exhibit strong attention to detail to ensure objects get finished correctly.

Being able to communicate effectively is necessary. Moreover, you will require excellent organizational abilities to manage all aspects of 3D printing processes effectively.

Is 3D Printing a Good Career?

Like any other job, if you have a real desire for 3D printing jobs and want to develop your creative and technical skills, then being a 3D printer operator is a great idea.

There are many things, technologies, and skills you can learn from like-minded individuals within your workplace, like software developers, 3D designers, and more.

Additionally, it provides many substantial benefits to society. From more affordable health care to reducing environmental degradation and ensuring manufacturing efficiency, there is a lot that 3D printing technology offers.

With a conducive working environment, being a part of these crucial global changes is very fulfilling.

What Professions Use 3D Printing?

With people looking for more straightforward and reliable ways to get goods, many are seeking services from the additive manufacturing industry. There are many 3D printing applications, from product design to designing medical equipment, architectural visualization, plus more. Here is an in-depth look into some of the top ones:

-

Aerospace

Aerospace parts must withstand chemicals and extreme temperatures while getting subjected to continuous loading and remain as light as possible. Component failures often cause the entire system’s failures. Since precision is critical for aircraft, aerospace engineers use 3D printing inspection tools to economize on costs for small parts.

-

Automotive

The automotive sector is utilizing additive manufacturing, with many companies using 3D printers. Everything from racing cars to sub manufacturers relies on 3D printing technology. The most common printed parts are fixtures, prototypes, and cradles, which require sturdiness and durability.

-

Manufacturing

Companies create custom, low-volume tools and fixtures at more affordable prices than the norm, giving engineers and designers more time to concentrate on revenue-generating parts. Small manufacturers have similar merits with 3D printers as giant manufacturers to enhance and accelerate processing while reducing downtime.

Companies also can exploit more creative ventures while saving on time and labor costs. Metal fabrication companies approach 3D printing using additive manufacturing, saving them lots of revenue.

-

Robotics

Parts like sensor mounts and grippers are expensive to construct, so they should get custom-designed for various uses. Robotics engineers use 3D printers for end-use parts and end-of-arm tooling, from gripping fingers to the entire components to minimize the final object’s weight. This way, they ensure tools move faster and can carry heavier goods.

Instead of paying chunks of cash for non-customized designs, Markforged 3D printers permit robotics industries to design and make light, yet complex parts such as end-of-arm tools at a lower cost than the usual price.

-

Education

With the 3D printing industry growing, institutions want to ensure they remain on the cutting edge of this technology for education and research purposes.

From professors making objects for educational tools to portray lesson plans to Ph.D. students using them for research, 3D printers serve a series of colleges’ functions.

For educators, understanding 3D modeling and printing techniques is invaluable.

-

Legal Professionals

With the increasing accessibility of 3D printing technologies, infringers can make, market, and sell items that infringe copyrights, patents, and valuable brands easily. New business models are likely to emerge where customer products and their constituents can get copied, juxtaposed, modified, and reproduced almost anywhere.

Because of this, IP enforcement lawsuits and actions and increased infringement monitoring are becoming more commonplace.

-

Construction Industry

The construction industry currently has six main 3D printing applications. These differ both in maturity and character. This technology aids in constructing printed molds, buildings, bridges, architectural models, building parts, and interior designing.

How Do You Work a 3D Printer?

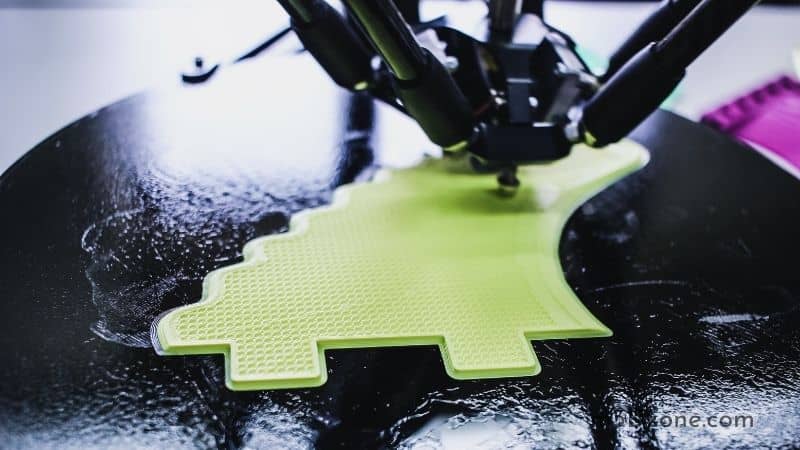

You start with object design on your computer. Connect the computer to your 3D printer, click ‘print’ and then wait for it to complete. The 3D printing process is like making loaves of sliced bread but in a reverse manner.

Imagine making individual slices of bread then sticking them together to form whole loaves rather than beginning with the entire loaves then slicing them.

3D printing processes combine many little pieces to come up with the finished objects from the base-upwards, piece by piece. The individual layers glue together to create a solid. Every layer can have high complexity.

These machines can make moving components like wheels and hinges as bits of one object. You can print an entire bike with the saddle, frame, brakes, pedals, wheels, and chain fully assembled without needing tools. All you need to do is leave gaps in the sections required.

What Is a 3D Printer Operator?

3D printer operators are proficient individuals who specialize in additive manufacturing. They majorly use (CAD) computer-aided design to map and develop objects getting manufactured in a layer after layer sequence. This is a relatively new job whose demand is slowly on the rise.

The roles of a 3D printer operator might be more complicated than you think. There are multiple diverse classifications and duties that can make one a 3D printer operator, not to mention various niche skills.

What Skills Are Required for 3D Printing Employment?

If you want a 3D printing job, the best method to achieve this is having some good experience with 3D printing techniques and processes and knowing the most widely used software.

A company may also require applicants to have experience with software like Netfabb and Rhino 3D, useful in 3D modeling. You should cooperate reasonably with other people and follow detailed instructions if you want to thrive in 3D printing jobs.

Some common skills all people in the 3D printing industry require to include:

- Keen interest in details

- High mechanical ability- get to know how each component works

- Good communication skills

- Excellent organizational abilities

How Do I Become a 3D Printer Operator?

The best approach to becoming a 3D printer operator is by attaining the first-hand experience with 3D printing machines. Most jobs need at least a year’s experience in 3D printing, plus some knowledge of the software involved.

Bachelor’s degrees in relevant fields like general science and engineering will help show your ability to acclimatize quickly to the 3D printing industry.

There are several kinds of 3D printing, like SLA, FFF/FDM, SLM, DMLS, and so on. Therefore, familiarizing yourself with the different methods found in the additive manufacturing industry will indicate your willingness to understand new 3D printing methods.

If you’ve done various projects and independently solved problematic situations in your way, this showcases your technical capabilities and how valuable you will be in future projects.

It’s always good to contact multiple 3D printing companies and find out which skills they are after. With the 3D printing industry being relatively new, there is a shortage of operators, so they will likely help and gladly answer your questions.

There are various 3D printing courses you can engage in and numerous forums to aid people daily on whichever questions are bagging them. Reddit, for instance, has a wide range of 3D printing enthusiasts with lots of valuable information and designs you can try to print or admire.

Final Thoughts

There are so many opportunities available in this industry. You can enjoy these jobs as project engineers, application engineers, software engineers, software developers, 3D designers, model makers, etc.

The 3D printing community has lots of people who want their colleagues to succeed, so it is a great industry to join. Once you show a desire to excel and commitment to the 3D printing industry, it’s easier to transition into a successful 3D printer operator.

Recommended Reading

How to Clean a 3D Printer Nozzle?

How to clean a 3D printer nozzle? Different ways: brushing the nozzle, then heat it and use a wire to remove the dirt. Or, you can soak the nozzle in acetone.

Top 8 Best 3D Printer Software for Mac Users (FREE Included)

You like 3D printing and have a Mac. What 3D printer software for Mac do you use? Let us guide you and show our top 8 picks. Some are free some not.

Can You Leave Loaded Filament in 3D Printer?

Yes, you can leave filament in 3D printer! Most 3D printing enthusiasts tend to leave commodity filaments in the extruder between 3D printing sessions.