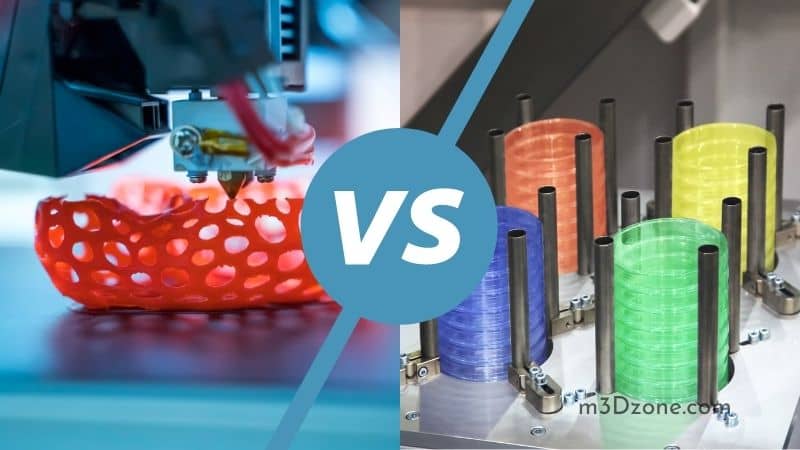

What manufacturing method will give me the best results? Between 3D printing and injection molding, which is more cost-effective? These are some of the questions bound to come to your mind when you think of 3D models.

Well, both manufacturing methods have their distinct manufacturing processes that yield promising results.

When deciding which manufacturing method to use in making 3D objects, 3D printing and injection molding are great options to explore. The injection molding process involves adding molten material into a mold cavity.

Quick Navigation

The molten material cools down and assumes the shape of the cavity. 3D printing, on the other hand, involves printing one layer of filament at a time on a build platform until you have a complete 3D object. To help you understand these manufacturing methods better, we have prepared this comprehensive guide.

What is the Difference Between Injection Molding and 3D Printing?

Both manufacturing processes are meant to help people create exquisite 3D objects without much hassle. With either device, prototype development is straightforward.

You can also create a spare part of any object. Despite these and other numerous similarities that 3D printing technologies and injection molding share, there are a few differences.

The first distinction is that 3D printing technologies use an additive manufacturing process.

You create objects by adding one layer of filament after another, following a predetermined pattern. 3D printers give you the advantage of being able to watch as each layer is built. This comes in handy when you are developing a new conceptual design.

In injection molding processes, you must have molds that you will pour your liquified molten build material.

Once you have injected the molten material into the mold, you have no choice but to wait for it to cool down before seeing the results completely. When the object is ready, you can eject it carefully to ensure you don’t break off some of its parts.

It would be best if you made the mold’s cavity in the shape you want the object you create to be in. each detail of your object needs to be captured by the object’s inverse. Otherwise, you will be left with an object that misses important details or an undesired element challenging to correct.

Injection molding is done using an injection molding machine. The machine is a bit expensive, but it facilitates the complete product development cycle. The product development cycle involves the loading of molding material, the cooling process, and finally, the ejection of complete designs.

In most cases, people customize their molds. Before they customize the mold to use in injection molding, it is important to first consider the manufacturing model’s specifications. Doing so helps you determine whether you will use aluminum, steel, or another type of metal.

Now, as you customize your mold to facilitate the injection molding processes, make sure you create it in two halves. If you create one mold, you will have a challenging time when ejecting the completed model. Halves molds, on the other hand, are easy to eject from since they are already split.

You may be wondering, now that I have two halves of mold parts, how will I load the molten material? Well, the design of mold parts gives room for runners. Runners are special hollow points that enable you to load molten material into your injection molding machine easily.

The 3D printing processes are the opposite of the injection molding processes. For a 3D printing project, you need a 3D printer or a 3D pen. Let’s focus on 3D printing using a 3D printer for now.

3D printing technologies demand that you develop a digital model of the 3D object you intend to create. For this process, you need a computer and 3D modeling software.

Develop the shape and other physical characteristics of your 3D project, including dimensions. It would be best to load the model to your 3D printer in a CAD file though you can still use any other compatible digital file.

This next part is somewhat magical. Your printer will build the object from the bottom-most layer, one at a time, as you watch. Note that the dimensions must be translated to the real-life measurements, rest you end up with bigger or smaller object parts than desired.

When the printing process is done, allow the plastic filament layers to cool before you can touch or move your 3D object.

Related: Can You 3D Print Silicone?

3D Printing VS Injection Molding Facts

-

Injection Molding vs 3D Production Volume

In the comparison of injection molding vs. 3D printing, production volumes come up as a major difference. An injection molding machine is better when it comes to producing high-volume objects. If you have multiple 3D manufacturing projects, injection molding is your solution. You will produce numerous units or parts of objects at a low cost per unit.

On the other hand, using 3D printing technologies gives you lower production volumes. If you don’t have rapid prototyping needs, 3D printing technology will give you satisfactory results. However, for a high-volume prototyping process, it is best to invest in injection molding tooling.

-

3D Printer and Injection Molding Modification

One of the things you cannot do when using injection molding is modifying already created mold. If you are not pleased with the shape of the units you have created, you have to edit these units’ designs once they are complete, then recast the mold. This makes injection molding unfavorable for prototyping testing.

3D Printing, on the other hand, utilizes computer technology in the place of mold. Whenever you are not comfortable with design, a 3D printer will accommodate any changes you make to ensure you produce satisfactory product quality.

You might like: What Is 3D Printing Used For?

-

Time Consumption

If you are looking at the time involved in per part creation, injection molding consumes the least amount of time. This, however, is based on assuming the custom-made mold was already created.

If you have included the time spent in customizing the mold from your metal type of choice, 3D printed parts will take less time. The size of the pieces you are making also determines how much time will be spent. Bigger parts naturally consume more time. You choose to set the price of an object based on the production cost per 3D part.

Is 3D Printing Cheaper Than Injection Molding?

Buying an injection machine is a bit tricky due to its price. For this reason, only a few dedicated stores sell these machines since they require a considerable upfront payment. Nonetheless, once an individual has purchased an injection molding machine, they get several productive years of using the machine.

If you cannot afford to buy your machine, don’t worry. There is still a more cost-effective option. Use injection machine providers to complete the tasks you are hired to do. Once you close manufacturing project deals, you will use your provider’s machines to produce parts of the units you are creating.

Consider the price of a 3D printing device before you draw your conclusion. The different types of 3D printers are relatively cheap compared to injection molding machines. Filament and a few other printing resources, such as cleaning filaments, are all you need to begin the additive manufacturing process.

Is 3D Printing Injection Molding?

The short answer is no. 3D is a method of making 3D-printed objects, and injection molding is a method of manufacturing injection-molded objects.

It would help if you had an injection molder in injection molding, which costs thousands of dollars. 3D printers, on the other hand, are less expensive but have a lower volume production.

The manufacturing of 3D printed objects is additive manufacturing, while injection molding uses injection molds to create an appealing product design.

How Long Does an Injection Mold Last?

How long an injection mold lasts depends on factors such as turnaround durations in making different parts.

With a faster turnaround, you will have way more production runs, creating more object parts. Eventually, a mold with a faster turnaround will last shorter than once used to produce more parts.

Conclusion

It doesn’t matter which article or blog you read; the bottom line is that injection molding and 3D printing share some similarities and differences in some aspects. You can create products of any size depending on your preferences.

However, if you want bigger production volumes, injection modeling is the most appropriate manufacturing method.

Recommended Reading

Stepper Motor Cooling. 4 Easy Ways to Do It!

Stepper motor cooling guide. When it comes to cooling your stepper motors, you have two main options: active cooling and passive cooling. Let's see more!

3D Printer Not Extruding Enough?

Is your 3D printer not extruding and you don't know why? Let's dive into it and find out what the problem could be.

Easy Guide to Start with Non-Planar 3D Printing

Non-planar 3D printing is a relatively new technology that produces smooth surfaces on nonplanar surfaces. Let's find out more inside!