What do you want to print? Which is the cheapest and most effective 3D printer that will satisfy your needs? Most people often wonder how many types of 3D printing are out there.

Others wonder why there is more than one type of 3D printer. Did you know you can 3D print a house these days? Well, your specific 3D printing needs to determine the type of 3D printer you will use.

Different types of 3D printers are available to meet the needs of different users. Depending on your 3D printing needs, you can use any 3D printer with the following 3D printing technologies: Fused deposition modeling, stereolithography(SLA), digital light processing, selective laser sintering, selective laser melting, and laminated object manufacturing, or digital beam melting.

Quick Navigation

- Why Do We Have Many Types of 3D Printers?

- 10 Types of 3D Printing Technologies

- 1. (FDM) Fused Deposition Modeling

- 2. (SLA) Stereolithography

- 3. Digital Light Processing (DLP)

- 4. (SLS) Selective Laser Sintering

- 5. Selective Laser Melting (SLM) 3D Printing Technology

- 6. Material Jetting (MJ)

- 7. Laminated Object Manufacturing (LOM)

- 8. Binder Jetting (BJ)

- 9. Electron Beam Melting (EBM)

- 10. Drop on Demand (DOD)

- Wrapping Up

Read through this comprehensive guide on the types of 3D printers and how to use each.

Why Do We Have Many Types of 3D Printers?

Before we dive into each 3D printing method, let’s first understand the reasons behind having these different types. Note, that each method is beneficial in creating a distinct 3D design.

The speed of printing is one of the most incredible upsides of using 3D printing technologies. People who use traditional manufacturing processes often take longer durations to produce simple objects. This is primarily because the objects’ shipping components take a lot of time to assemble.

If these people turn to additive manufacturing processes, they will produce the same objects in hours. Various types of 3D printers have the power to turn whichever CAD file you have into desirable objects fast.

With these production speeds, manufacturers can make more money through the rapid production of valuable products.

With standards being set by the economy, manufacturers are forced to produce products following strict criteria. For instance, some dimensions are followed when making a teacup. If you manufacture a teacup that is not in the size most people are used to, chances are it will not sell as much.

Similarly, if you want a teacup in a unique size, you might spend months or even years looking for one. 3D printing technology comes in to help you customize teacups and other objects in sizes, shapes, and designs of your choosing. All you have to do is make a digital design with the specifications of your choice.

Printer cost is another important reason for having different types of 3D printers. The price of buying each printer differs depending on its type and model. Once you invest in 3D printing technology, you no longer have to struggle with injection molding or otter machines. You make all 3D models you want using your desktop printer conveniently.

3D print quality is first-class if you use high-quality printing material. You get to enjoy the diverse capabilities of these devices as you create unusual objects.

Keep in mind that 3D printing is easy: both adults and children can operate any 3D printer type comfortably. Once you have developed the digital 3D model you are going to use, you only need to set your 3D printer then command it to begin printing.

10 Types of 3D Printing Technologies

Here are the ten distinct types of 3D printers we’ll discuss in detail.

- Fused deposition modeling (FDM)

- Stereolithography(SLA)

- Digital Light Processing(DLP)

- Selective Laser Sintering (SLS)

- Selective laser melting (SLM)

- Material Jetting (MJ)

- Laminated objects manufacturing (LOM)

- Binder Jetting (BJ)

- EBM

- Drop on Demand (DOD)

1. (FDM) Fused Deposition Modeling

In 3D printing, fused deposition modeling (FDM) printing technology is among the top recognized and preferred printing types. FDM technology is often referred to as Fused Filament Fabrication (FFF.)

The origin of FDM printing technology is in Stratasys, where Scott Crump developed it. Scott went ahead and implemented the use of FDM technology in 1980. After Scott, other manufacturers made attempts to replicate and possibly improve the functionality of this printer.

FDM 3D printers are now helping people all over the world in creating operational prototypes. With these, you can create prototypes of any product you wish to introduce in the market.

You are probably wondering, how do these printers work? FDM 3D printers extrude plastic filament in one layer simultaneously, helping you create a 3D object from the bottom.

The 3D printing process in these 3D printers involves temperatures rising to the melting point of the thermoplastic filament you use. Once the filament has melted, it will be extruded through the 3D printer’s nozzle.

Related: How to Clean a 3D Printer Nozzle

Melted filament lands on a printing bed or a build platform following the pattern you created your digital model in.

FDM technology utilizes high-caliber thermoplastic, meaning you can print material components to be used in various engineering fields. FDM prints are strong, and you can mold them to give you a surface finish that meets your needs.

These FDM printers have programs that precisely program how your printer will extrude layers of thermoplastic filament after the CAD models have been sliced accordingly.

Thermoplastic is not the only material that FDM 3D printers extrude. They also extrude support material, which is beneficial in making support structures.

FDM technology printers, like any other desktop 3D printing method, will help create a computer-aided design. You, therefore, need to have slicer software running on your computer during the 3D printing processes.

Slicer software translates your model’s dimensions, ensuring the printer’s nozzle makes movements that create an object with accurate measurements.

In an FDM 3D printer, you extrude a thermoplastic layer that binds with the previous layer melting and hardening it afterward. Once one layer is finished, your object’s base lowers to make room for printing another layer. This printing process continues until you have complete 3D objects.

2. (SLA) Stereolithography

An SLA 3D printer is the oldest printer that utilizes additive manufacturing printing processes. An SLA machine printing process involves exposing layer after photopolymer resin to UV light in a UV-laser beam.

The photopolymer resin in your SLA 3D printer will harden following the pattern you had made in your digital model.

Are you worried about your SLA 3D printers creating 3D objects that are out of shape? Worry no more. Stereolithography gives you objects with distinctive shapes since the SLA 3D printers build objects one layer at a time.

When you are done with your 3D printing process in stereolithography, you need to rinse the 3D object in a solvent. This helps your object in completing its curing process to ensure it is long-lasting.

3. Digital Light Processing (DLP)

DLP 3D printing technology shares some similarities with stereolithography (SLA.) Nonetheless, there is a difference in the way DLP and SLA 3D printers work.

DLP makes use of a digital light projector. This projector flashes one image of every 3D printing layer once. If you are printing more prominent parts, the digital light projector will flash multiple times.

In digital images, layers making up an image or model are composed of square pixels. DLP technology is not different; it has a digital projector that has a digital screen that forms layers from small rectangular blocks.

Exposing a complete printing layer once gives DLP 3D printers an advantage over SLA printers. You will find that your SLA printers will trace your printing layer’s cross-section using one point of a laser, which slows down 3D printing processes.

The advantage of using DLP printing technology is its printing speed.

Digital light processing 3D printers use micro-mirrors to control light and are usually faster than SLA printers. This means you can make more 3D prints in the DLP machine in one day than you can make in stereolithography.

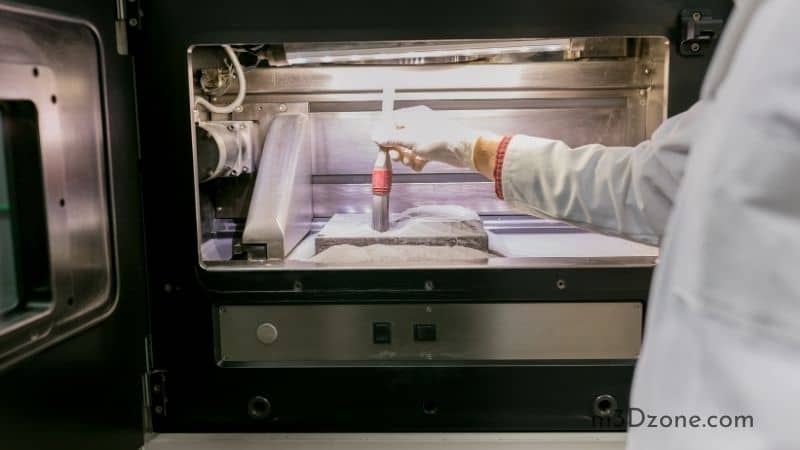

4. (SLS) Selective Laser Sintering

In the diverse 3D printing technologies, we also have selective laser sintering (SLS). An SLS 3D printer makes extraordinary 3D designs by sintering tiny polymer powder particles using an intense laser to form a solid object.

Whenever you are printing with a selective laser sintering (SLS) 3D printer, you don’t need support structures since the unfused powder supports each layer. You can therefore use SLS 3D printing technologies in complex geometries.

Since you make objects by sintering small polymer powder particles, SLS printing gives you substantial parts of any structure or object. These SLS printed parts contain mechanical properties that make them even better suited than parts manufactured through injection molding.

Most people who use SLS printing technology often use nylon as their printing materials. This is because nylon is flexible, meaning you can make objects of any size easily. It is also light giving you the advantage of making objects that are easy to carry.

Nylon is also stable when exposed to various conditions such as heat, sudden impact, chemicals, and wetness. The 3D objects you make with these 3D printers last longer than those made with some other desktop printers.

The price of buying a 3D model made using printers that use SLS printing technology is relatively low. This is because these printers are highly productive with a low cost of producing any part or object.

The unique features of selective laser sintering make it best applied in making functional prototypes. SLS also comes in handy in custom manufacturing and assembling of end-use parts.

5. Selective Laser Melting (SLM) 3D Printing Technology

Like SLA printers, SLM makes 3D object parts using high-powered laser beams. SLM 3D printers’ printing processes involve metal powder being fused after being heated to its melting points by laser beams.

Consider this perspective; you have your metallic powdered material, the laser beam will heat it with precision giving you layers of filament that form a structure. The result is a magnificent 3D object that encompasses all the features of your digital design.

The logic behind SLM printing is like that of traditional welding. When the laser beam is directed towards your metallic powder printing materials, it will weld the particles to give you a complete layer.

You will then keep printing one layer after another until you have a complete 3D object. There is no fear of getting objects that are out of shape since your SLM 3D printer lowers the object in the printing process once each layer is complete.

6. Material Jetting (MJ)

The way a regular desktop printer works is similar to how material jetting 3D printers work. What differentiates these two printers is that a material jetting printer will print multiple layers of material to form an object. Inkjet printers, on the other hand, only print one layer of ink.

Uniqueness in making 3D objects using these printers comes from photopolymer droplets solidified by UV light. This happens after the droplets have been jetted out in hundreds by the printer’s print head.

If you are a fun-loving person, you will enjoy watching as your MJ 3D printer lowers a fully solidified layer until a complete 3D object is created. You can involve your kids in the printing process as they learn 3D printing skills.

MJ 3Dprinting is being preferred by a majority of people today. This is because, unlike SLA, FDM, or the other printing types, MJ can print several 3D objects in one line without reducing the printing speed. If you are in a field that requires the rapid production of objects, this is a superb 3D printer to use.

You only need to align the models correctly and command your 3D printer to begin its printing process. For instance, if you are producing a specific jewelry design, arrange your models in the order you would like to print them, and within no time, you have your jewelry pieces ready.

However, you will need to remove the support material you use in making these 3D figures in the post-processing stage of production.

7. Laminated Object Manufacturing (LOM)

If you have been typing, “how does a LOM 3D printer work?” on search engines, your search ends now. These printers use heat and pressure simultaneously in laminating various layers of plastic material to form 3D figures.

Due to this combined pressure and heat in printing materials, LOM is often used in rapid prototyping. One can produce multiple prototypes fast without much hassle.

You have the advantage of utilizing the printer’s computer-guided laser in cutting your 3D figures in the shapes you want. The printer’s build platform lowers upon full printing of a single to create room for another layer.

Here is a step by step explanation of how LOM 3D printers work:

First, using a heated roller, a printing sheet will adhere to a substrate. A laser will then trace the predetermined measurements of the prototype you are manufacturing.

Third, the laser will cross the non-part areas facilitating more efficient waste extraction. The build platform is lowered in the fourth step to give room for printing a separate layer.

The fifth step is rolling a new printing sheet and repeating the above process until all layers of your 3D object are complete.

8. Binder Jetting (BJ)

If you want to make parts of an object using sand, a BJ 3D printer is what you need. These devices have reduced construction costs by a considerable margin.

For instance, if you want to construct a house using gypsum technology, you will get 3D-printed gypsum materials at a low price. All you have to do is contact an engineer with BJ 3D printing skills.

Whenever you make full-color 3D printed models, it will be best to use a combination of plaster-based powder and a liquid binding agent.

Ensure you remove the 3D parts you print out from the unbonded powder once they have fully solidified. Now clean the newly created parts and expose them to an infiltrant material. The exposure will enhance the 3D object’s mechanical properties.

If you are not content with the vibrance of the object you have just created, you are free to add a coating of your choice.

9. Electron Beam Melting (EBM)

Starting the EBM printing process is not different from SLA or any other printing technology. You must make a 3D model or CAD file before moving to the physical printing of 3D models.

There is a similarity between EBM printing technology and SLM printing technology. They both use powder bed fusion techniques.

The difference between EBM 3D printing technology and SLM technology is on the type of beam and space used. You see, in SLM technology, there has to be either an inert or a noble gas plus a high-powered laser. EMB technology, on the other hand, demands a vacuum and an electron beam.

Since the EBM 3D printing process uses an electron beam, it is effective in making metal parts. If you use this type of printer, you can create as many metal parts as you need inexpensively.

No matter how complex geometries get, making 3D print parts with EBM printing technology is always convenient. This is because EBM technology gives you freedom of design. You will end up with 3D parts that are quite strong for use in a wide range of fields.

EBM 3D printers are highly efficient when it comes to utilizing raw materials. They give you a platform to make durable 3D parts that you can sell and make good cash.

10. Drop on Demand (DOD)

Unlike most 3D printing types like SLA, DOD 3D printers use two injects to make 3D-printed objects. The function of one of the inkjets is to deposit wax-like build material.

Your DOD printer’s second inject jet deposits dissolvable support material to strike a balance in the composition of your printing materials.

A DOD 3D printer is similar to an SLA printer since it also jets material following the pattern you create your 3D model in. It also creates one layer after the other to give you a finished 3D model.

Wrapping Up

With every passing day, people worldwide embrace 3D printing technologies and the different types of 3D printers that come with them. Your 3D printing needs are the ones that determine the type of 3D printer you will use.

Nonetheless, consider how each 3D printer works before you buy it. The materials used in different 3D printing technology types differ depending on the specific type of 3D printer and the desired final product.

Recommended Reading

3D Printer Calibration. How to Calibrate 3D Printers

Does your 3D printer calibration affect the print quality of the finished print? Check out our easy guide on how to correctly calibrate your 3D printers...

Best 3D Printer Build Surface

So what is the best 3D printer build surface? Each one has its merits and limitations: for a super-smooth build surface pick a glass build; also try BuildTak.

What Is 3D Printing?

In simple words, 3D Printing is the process of making 3D models using 3D printing devices. With an HQ 3D printer, you will be able to create 3D models rapidly.