To understand the difference and the similarities, you need to understand each machine.

A laser cutter works by cutting away material to create an object. It is a subtractive process machine. On the other hand, a 3D printer works through an additive process where objects are created by adding layers, and that way, a 3D model is created.

Quick Navigation

3D printers and laser cutter machines are tools used by creative people. With these two, one can teach and improve their creative skills. The devices are all cutting-edge, which is where the comparison comes.

Both devices depend on software to create the desired object. Some models have software and screens in them. That way, the user operates them directly without the need for a computer. Also, some models may need computers so that they can direct the devices.

In this article, you will read all information there is on 3D printers and laser cutters. You will understand their differences, benefits, and how to combine them to work together.

What Is the Difference Between a Laser Cutter and a 3D Printer?

These two devices are different from each other in a couple of ways. The main difference is the subtractive manufacturing process. It creates designs and objects by cutting materials into the shape designed in the software.

A 3D printer is an additive manufacturing process where it makes its designs by adding up layers of materials and creating a design.

Related: 3D Printing vs Injection Molding

Are 3D Printers a Waste of Money?

Let’s dive into why some people think that 3D printers are a waste of money and should not be bought.

-

Why 3D Printers Are Worthy Investments in 3D Printing?

With 3D printing, anything is possible as long as you can imagine it and make a software model used to create the actual object. 3D printers have helped solve real-life problems like body organs used in the human body when the human one fails.

Apart from that, it has increased speed in producing objects that could have taken ages to create. It has also helped cut the cost of production and, in return, increase the profit in which producers make.

Years back, printers were expensive, and most individuals could not afford them. Now you can get a good quality 3D printer at roughly $250-$300 only, maybe even cheaper.

Operating a 3D printing device may take time to master, but you get to learn a lot with time. It even helps improve creativity because with 3D printing, if you can imagine something for a project, you can create it.

The cost involved in running 3D printing is the basic replacement, and they aren’t expensive.

So many businesses can run with 3D printing, especially when you are a creator, as you can come up with your design and sell them to people and end up making a lot of money.

-

Why a 3D Printer Isn’t a Good Investment

If, in any case, you don’t enjoy technology or trying new things, then a 3D printing device is a bad investment for you. In most cases, you will get it, use it a few times, then leave it. You will not complete any project or add any 3D print to the world.

You may even waste important powder material that one other person would use to create a piece that completes their project.

With 3D printing, you will need to keep replacing the filament for the printer to work efficiently.

Filament will cost from $15 to around $50 per kilogram of the material you are using.

You need to know quite a lot so that you can operate the 3D printing device efficiently. One is assembling the whole piece. Apart from that, you need to know how to deal with troubleshooting prints.

As seen above, you will need to replace filaments and also designs with time. The first few times will be frustrating as you learn, but with the time you’ll master.

Instead of going through all the troubles, you can borrow the 3D printing device for a few hours at a small fee to print and pay the fees for the materials you use.

How Do You Turn a 3D Printer Into a Laser Cutter?

You can turn your printers into laser cutters by the use of endurance laser add-on modules. The best part is while converting: you don’t need to strip away the extruder. The Endurance add-ons have an adapter that needs to first mount the laser to the print head using a little fuss.

For example, if you have a 10-watt laser, you need to run those laser add-ons to reduce the power supply for each laser’s M01 box. If your laser is 5.6watt and any other low power models, reducing the power is optional.

After you reduce the control box’s power, do the same to the laser’s fan and the access on the 3D printer fan outputs, which is on the mainboard.

Keep in mind that after you have hooked the laser module and the print carriage is mounted, the process is quite easy when you use the right g-code.

At this point, M03/M05 or the M106/M107 commands will turn the laser on and off. Control the intensity by using the command S.

Can You Make Money With a Laser Cutter?

Yes, you can make money with laser cutting through the following ways:

-

Making Barcodes With Laser Cutters

By laser cutting, you can make barcodes, which are made using chemicals like CerMark. The barcodes are made on tools, and when the workers take a certain tool, the tool barcode is scanned together with the workers’ barcode. That way, the company can tell which worker has a certain tool.

-

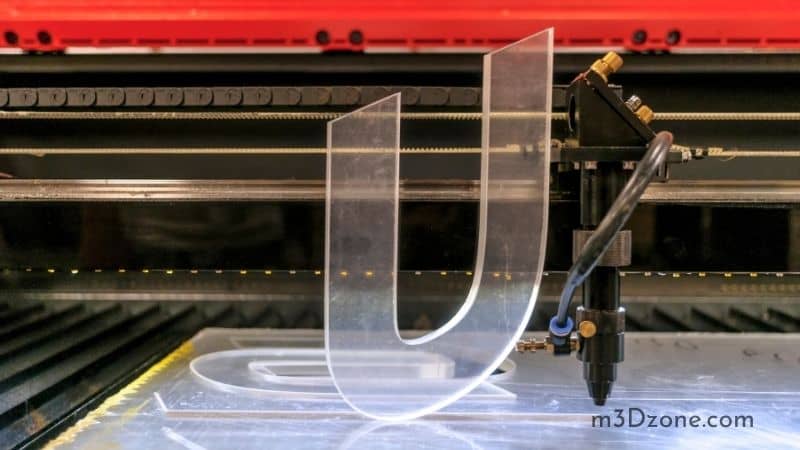

Acrylic

With laser cutters, laser engraving is possible by putting logos on acrylics. That way, they are not only elegant but customized.

When people use the rotary devices to make the engraved logos, they don’t look as good as when the laser cutter is used. This is why most customers prefer laser cutting.

-

Making Products With Multiple Languages

Some companies are global and they serve countries with different languages. When awarding workers, they use laser engraving on award using multiple languages to serve all the countries. All you need with a laser cutter is to have the wording and the formation of all the information to include, and that way, you will come up with a perfect design even without knowing how to read the wording on the product.

-

Plastic Signs and Advertisement

When individuals are making signs or advertisements for the wall doors or even an informational sign, they use plastic. With laser cutters, it makes plastic signs way cheaper than other devices, and there is less work. With the low cost, the profit will increase for the person using the laser cutter.

Should I Get a Laser Cutter or a 3D Printer?

A laser cutter makes its pieces flat and makes it ideal for creating angular models and designs for those that need a flat layer. With 3D, it makes irregular models and, at times, can have scratches.

The two devices are both important. For example, the 3D printing device can be used to make a prototype before making the final model test whether it is good before making the final production.

3D printing is an additive manufacturing process that requires 3D modeling software to make a 3D file for your model. Laser cutter manufacturing methods on the other hand do not use the same technologies like a 3D printing process.

Laser cutter technology needs lasers such as a tube laser to turn an idea about fashion accessories or other products into reality. With the right powder, you can take advantage of laser cutter technologies and create resin parts to make products that are in high demand using.

Laser cutters are more expensive than printers but more reliable because 3D printers tend to jam more.

For laser cutters, it creates models and prototypes fast as compared to 3D printing. For a 3D printing device, you have to create a model first from the filament material, which will take more time and materials.

When creating something large, the laser is better as all it needs is to cut the unnecessary materials. If in 3D printing the design is large, it has to be divided into units.

With a laser cutter, you have a wide range of materials to create your models from, unlike 3D printing.

What Is Laser Cutting?

Laser cutting creates models by cutting into the material and removing the unnecessary parts, using the powerful laser beams that melt, burn and evaporate the cut materials.

It is a fabrication process that uses a thin, focused laser beam that cuts into the material and design, patterns, and shapes. With the process, you have a wide range of materials which include: wood, glass, paper gemstone, metal, and plastic.

Benefits of Using 3D Laser Printer

- With a laser 3D printer, you get many choices of materials and you can create many items.

- It is easy to print using a 3D laser printer. Also, with the choice of materials, one can develop all kinds of objects, including jewelry.

- You can use acrylic to create your objects, which come in a variety of colors and even transparent, which gives you many options.

- When creating larger designs, it is cheaper and easier to use the 3D laser printer. That way, it reduces the price of the object.

Conclusion

When it comes to 3D printers and laser cutting, each has its advantages. Also, people’s preferences differ when it comes to choosing which is better.

But with all the information provided above, depending on your preference and work, it is easy for you to make the right decision on what’s best for you.

Recommended Reading

Is 3D Printing Hard to Learn?

Is 3D printing hard to learn? It can be overwhelming to beginners because most printers are delicate and meticulous. First of all, you will have to invest time.

Optimal ABS Filament Temperature for Your 3D Prints

What is the optimal ABS filament temperature? ABS has a relatively low melting point so that it can be printed at lower temperatures than other materials.

Multi Color 3D Printing. Can It Be Done?

Multi color 3D printing is a challenge as typical 3d printing prints a single color despite the technology you deploy. Let's see what options do we have!