Do you want your 3D prints to look professional? You can try to sandblast them. But, can you sandblast 3D prints?

As an Amazon Associate, I earn from qualifying purchases. If you make a purchase after clicking on a link I may earn a small commission at no extra cost to you.

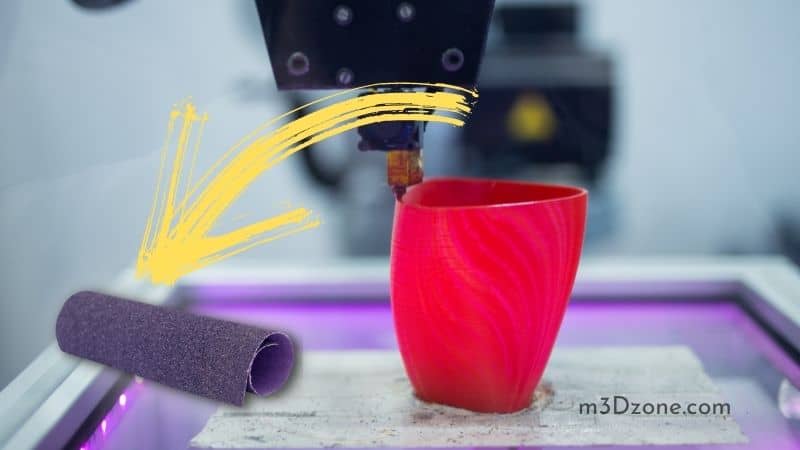

Here is a DETAILED guide on sandblasting to smoothen your 3D prints.

Quick Navigation

If you want your 3D prints to print smoothly and look professional, sandblasting is one method you can use to achieve a quality and smooth finish.

Other methods include vapor smoothing and sanding using sandpaper.

- But what happens if you sandblast a 3D print?

- Can you achieve the kind of polishing and smooth finish available from traditional manufacturing technologies?

- How do you deal with the visible layer lines from the FDM systems?

There is a variety of finishing techniques that will help you achieve your desired smooth surface finish. Each sandblasting method has its pros and cons.

For instance, one will be better for smoothening tight corners, while you may prefer another technique to get a shiny finish.

Here, we’ll look at the various sandblasting methods and their advantages and disadvantages.

Sandblasting a 3D Print. Can You Sandblast 3D Prints?

Probably you are wondering, “What happens when I sandblast a 3D print?”

When you are sandblasting a 3D print, sand is shot hard on the surface of the objects. During the process, the rough and even areas of the object fade away, and you are left with a rigid, smooth surface.

Using a sandblaster (check at Amazon) for your 3D prints is a quick and efficient process as you don’t have to exact any elbow grease.

The individual particles of the sand hit the surface of your object and break its tiny parts.

With hundreds of the particles, the print’s surface wears off, removing any imperfections from printing which smoothens the surface.

Ensure you are careful when sandblasting weak areas and corners, as you can sandblast them off. You can use sandpaper from your hand on the most delicate parts.

What Can You Shoot Out of a Sandblaster?

There are various things you can shoot out of a sandblaster, and each has its effects. Such things include:

-

Glass Beads

A glass bead on your 3D print helps deal with the surface defects and achieve a matte finish.

Some 3D print materials can have undesirable glossiness. Glass beads help polish the materials and remove any unwanted shine, giving your material a professional look.

Most people use glass or metal beads to achieve a smooth and desirable finish, giving your print a professional look.

The glass beads (check at Amazon) look similar to a crushed beer bottle ground into similar-sized pieces. The beads come in various grades.

-

Silica Sand

Silica sand (check at Amazon) is also a popular medium you can use with your sandblaster. The silica sand comes in various grain sizes, including fine, medium, and coarse.

Although silica sand is a popular medium, it is known to cause respiratory issues. As such, you should use a respiratory device that will prevent the sand from getting in.

The sand can also contain water that can cause corrosion of your sandblaster.

-

Silicon Carbide

Silicon carbide offers the most aggressive and quick form of sandblasting. It is recommended for use when you are sandblasting large areas that require a lot of time.

Sometimes it can remove too much material from your print.

-

Soda

You can also use baking soda (check at Amazon) to sandblast rust and paints from your print. It is cheap as you may already have some of it in your cupboard.

If you want to smoothen the surface slowly, soda is an excellent option. It is effective for delicate blasting.

-

Aluminum Oxide

If you want to use abrasive media for sandblasting, aluminum oxide is an excellent pick.

It is a versatile medium ideal for various purposes, including abrasive painting, refractory coating, etching to ensure coating adhesion and performance, etc.

You can use the medium for dry and wet blasting processes. Plus, it is a low-iron medium which ensures it doesn’t leave any rust on your print.

What Is Bead Blast?

Bead blasting is a post-processing technique where an operator holds a nozzle and sprays tiny, medium beads to remove layer lines from a print.

It is a quick process that takes about five to ten minutes and leaves your parts smooth.

Bead blasting is a flexible process as you can use it with most FDM products. You can also use it with parts throughout their production process, from prototyping to production of the final product.

Can You Use Compressed Air to Sandblast?

Yes, you can use an air compressor to sandblast. Sand blasting uses compressed air to hurtle fine materials such as sand on the print to remove scales, paint, rust, and fill holes caused by grease and oil stains and heat.

What Is Dimensional Accuracy in 3D Printing?

Dimensional accuracy in 3D printing refers to how well your object matches the specifications and size of the original file.

To get the most accurate results, ensure you select materials and the most appropriate printing process for the design.

What Affects Dimensional Accuracy?

Since 3D printing is imperfect, you should make decisions that affect the final dimensional accuracy when designing the object. Such decisions include the materials the object will be made of and the printing method.

When you finalize the design, you can then take steps to ensure the final product will be as accurate as possible.

Factors That Will Affect the Accuracy of the Final Product

- Support structures: you may require support structures during the process to ensure accuracy. However, the surface finish of the final product may be affected by the removal of the support structures

- Post-processing: the decisions you make at the final stages of production will affect the accuracy of the final product. Proper cooling can help to keep the final product in the best shape

- Warping and shrinkage: the materials used in 3D printing have the possibility of shrinking or warping. When making your final design, you should avoid flat surfaces, unsupported structures, and large expanses of materials, as they can all warp

- Materials: using the right material for your object will enhance the accuracy to which you can print it. Standard SLA resin can offer you more precision than flexible SLA resin

- Machine accuracy: some 3D printers will offer more accuracy than others

- Object size: It will be easier to achieve better accuracy with small objects than with larger ones. Bigger rooms provide more room for errors.

How Do You Finish 3D Printed Objects?

There are three methods that you can use to finish a 3D-printed object. These methods include:

1. Vapor Smoothing

The vapor smoothing method of finishing a 3D printed object involves putting the item in a vapor chamber. The vapor will melt the surface and help get rid of the imperfections on the product.

This leaves you with a shiny finish that you can sandblast later to achieve a matte finish.

Only a small amount of the material is affected during the process, and the parts fit together. It doesn’t cause problems with the pieces fitting together, but you may sometimes have to consider the affected materials.

Vapor smoothing is the most preferred method when dealing with consumer-level 3D printed items. It is used in industries dealing with building products, healthcare products, and car parts.

2. Sanding

You can also finish your 3D printed objects by sanding them either by hand or using a machine. Alternatively, you can also use a handheld electric sander. An electric sander is more appropriate for large areas that you’ll not be bothered to sand.

You can also use an electric sander if you print too many 3D printed objects that will be challenging to sand by hand. When you are through using an electric sander, you might have to use a hand sander to finish some parts well.

3. Bead Blasting

You can also use bead blasting, also known as sandblasting, to smooth out the printing lines and offer a smooth finish. Sandblasting provides a smooth matte finish, depending on the materials you use in making your 3D printing object.

Beach blasting is an excellent option as it enables you to reach the tight spaces that you may not reach using sandpaper.

Bead blasters feature different sizes of nozzles. You can adjust the size of the nozzle to get to the tight spaces that you may not reach normally.

Final Thoughts

So, can you sandblast 3D prints? You can sandblast 3D prints to achieve a smooth finish and professional look of the products.

The process can be affected by various factors, including the materials used, the presence of support structures, etc.

Recommended Reading

How to Fix 3D Printing Ghosting

What causes 3d printing ghosting? Ghosting, also referred to as jerking or ringing in 3D prints occurs when your 3D model has patterns that reoccur...

Casting vs 3D Printing. What to Choose?

Casting vs 3D printing. 3D metal printing gives you full control over the casting process, which is not the case with traditional metal casting.

3D Printing Over Extrusion. Easy Ways To Fix This!

3D printing over extrusion happens when your 3D printer extrudes too much material. Over-extrusion ruins the quality of your 3D models.