If you were to order food and drinks from a drive-through at your favorite fast-food joint, chances are the plastic packaging material in which your food is packed would be different from the soda bottle you’d get.

Despite both objects being made of plastic, they’re entirely different types.

Quick Navigation

- What Is PETG? Everything You Need to Know!

- Properties of PETG

- “Food Safe”. What Does It Really Mean?

- Factors to Consider When Evaluating Food Safety of a Material

- Is PETG Food Safe?

- Is 3D Printed PETG Food Safe?

- Vacuum Forming vs Injection Modeling. Which Is Better?

- I’m Thinking of Using PETG Plastic to Make Food Utensils. What Do I Need to Watch Out For?

- Is PETG Safe to Drink Out Of?

- Is PETG FDA Approved?

- What Are Some of the Benefits of PETG?

- What the Future Holds for PETG?

- Conclusion

The same thing can be discovered when you shop for food containers at your local store. While a specific aisle might be filled with plastic containers of different shapes and sizes, the types of plastic material used are different.

For years now, PETG food has attracted a lot of attention in the food industry. However, there are still concerns regarding its safety for consumption by households.

However, all these different materials have been specifically designed for the sole purpose of storing food items.

This kind of plastic can be referred to as PET, short for polyethylene terephthalate. Next time you buy a soda, you should be familiar with the term PET on the label.

Not only is this material suitable for making food and beverage containers, but also other objects such as plastic combs, pens, toys, etc.

In this guide, we’ll review everything there is to know about this material and whether or not it’s food safe.

What Is PETG? Everything You Need to Know!

As we mentioned before, PET stands for polyethylene terephthalate. Once you add the “G” at the end that stands for glycol, it becomes PETG.

PET-G is a type of plastic with high chemical resistance, extended durability, and is a safe food material in the food industry.

While both PET and PETG have the same chemical composition, with the only difference being the glycol added at a particular molecular level, PETG has more robust qualities than the former.

Properties of PETG

PET is known for its overheating problems. However, when combined with glycol to form PETG, the resulting compound becomes highly resistant to heat.

Some of the significant properties of PETG include:

- Hardness

- Transparency

- Chemical resistant

- Impact-resistant

- Ductility

- Thermal stability

These properties are what make PETG a food-safe material and suitable for 3D printing processes.

Its extrusion temperature ranges from 210 – 250 °C while its print speed falls between 40 – 60 mm/s.

“Food Safe”. What Does It Really Mean?

While this guide aims to discuss the levels at which PETG is food safe, it would be wise to consider what this term actually means. So, when is something said to be food-safe?

Basically, food safety is measured depending on whether or not the material in question can be in contact with food without causing any negative health effects on the consumer.

When various materials with different compositions are combined, it can change the chemical composition of the resulting product, and the particles involved tend to migrate on to the food eaten. In the event that these particles are hazardous, your health would be at great risk.

Factors to Consider When Evaluating Food Safety of a Material

You can ask yourself a few questions to determine whether or not a material is food-safe, including:

How Long Is the Expected Food Contact?

Take a meal prepping, for example. Preparing whole meals ahead of schedule would be wise if you’re a busy person. This also means that the food packaging containers used would come into contact with the food for extended periods. The safety of such an airtight container carries more weight for it to be considered food safe.

What Temperatures Can the Material Withstand?

Have you ever wondered why it’s never advisable to drink hot tea from a plastic cup? The theory behind this is that various materials such as plastic tend to emit toxic chemicals when exposed to extreme temperatures.

Can It Be Cleaned?

Cleanliness is often a factor that is neglected. The ability of a material or product to be properly cleaned is what determines whether or not it’s food safe.

For example, if your kid’s lunch box is made of a material that cannot be cleaned efficiently or uses regular cleaning detergents, it could promote bacteria growth. This could potentially transfer toxins into the food and adversely affect the child’s health.

Is PETG Food Safe?

PETG is considered food safe. However, this doesn’t apply to all PETG filaments. Every manufacturer in the food industry is expected to get separate FDA approvals for PETG plastics.

Even though FDA approval does exist for various brands, there are still other safety concerns on using 3D printed PETG.

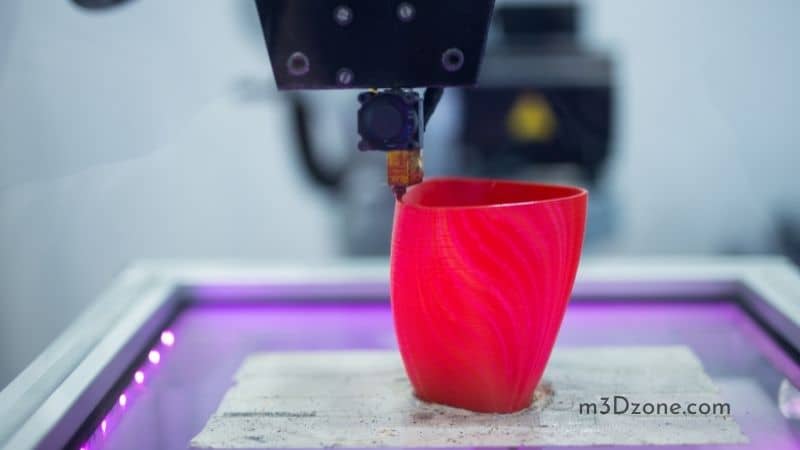

Is 3D Printed PETG Food Safe?

Yes, the FDA does consider 3D printed PETG food safe. However, you should also be aware that such considerations are targeted at printed parts formed through vacuum forming or injection molding.

What Is Vacuum Forming?

Vacuum forming is one of the two techniques of manufacturing plastic parts.

Also known as thermoforming, this method is suitable for large-scale designs in shorter production periods.

How Does It Work?

- The process is quite simple and economical.

- A polyamide sheet of material is exposed to high temperatures on a heated bed.

- It is then placed on a mold.

- A vacuum is used to suck out the air within the mold, thus, shaping the sheet against it.

- Once the plastic cools and hardens, it’s extracted from the mold and trimmed.

Advantages of Vacuum Forming

- Lower cost of tools used

- Flexible designs

- Easier production of prototypes

- Shorter production time

What Is Injection Molding?

This is another plastic forming technique suitable for small parts over longer production processes.

How Does It Work?

The process is quite common as compared to vacuum forming and includes:

- Under high pressure, hot molten plastic is injected between a mold cavity and core.

- Once the plastic cools and hardens, the part is ejected from the mold cavity.

Advantages of Injection Molding

- Efficient use of material and little waste

- High automation levels to save costs

- Advanced tooling with multi-cavity mold options

- Precise processing for large-scale production of small parts

Vacuum Forming vs Injection Modeling. Which Is Better?

While both methods are suitable for making plastic, injection modeling tends to be preferred for this raw material. It is also used to produce more than 60% of plastic products.

However, this doesn’t make it a better alternative because it also does come with limitations. For example, it’s complicated to produce huge parts using this technique.

However, injection modeling allows for more creativity in design than vacuum forming, and more items made of plastic around you are more likely to have been produced using this method.

I’m Thinking of Using PETG Plastic to Make Food Utensils. What Do I Need to Watch Out For?

So, you’ve decided to go PETG with your food utensils? Well, there are a few things you need to be cautious of, including:

1. Lead Poisoning From Brass Nozzles if a Possibility

A wide variety of PETG 3D printers have a soft brass nozzle that contains lead. If this element comes in doses above the standard ones, it could lead to lead poisoning.

It would be best to get yourself a printer that uses a high tensile plastic nozzle or other safe metals such as a titanium nozzle.

2. Small Cracks/ Holes Promotes Bacteria Buildup

FDM 3D printers are notorious for this issue during the printing process. You should always strive to have fewer holes than the expected standards because once food gets stuck in them, they become a breeding ground for bacteria. Ingesting this bacteria by using utensils puts your health at risk of infections such as E Coli.

You should always wash your PETG filament before and after printing. You should also ensure you use a high-resolution print to minimize any possibility of small cracks or holes substantially.

3. Additives in Filament

Even if you were to use food-safe filaments for your PETG prints, there’s a possibility that the manufacturer may have used a different kind of chemical compound in it. This makes it hard to determine how a printed object would react to extreme temperatures from food contact.

Stay away from any food-safe filament that contains unfamiliar additives. You might be exposing yourself to harmful toxins.

4. Using Sealants

Particular chemicals must be used to ensure that these printed parts are waterproof.

As such, it’s recommended that you use a sealant that is food safe and FDA approved for such purposes.

Is PETG Safe to Drink Out Of?

Yes. It’s safe to drink out of PETG utensils because they’re produced from food-safe filaments that are FDA approved.

When such material is FDA approved, you can be assured that the proper measures have been taken to guarantee your protection against harmful bacteria.

Is PETG FDA Approved?

Yes. PETG is definitely FDA-approved. However, you should always check the labels before buying any to ensure you’re familiar with any unrecognizable additives used.

What Are Some of the Benefits of PETG?

Recyclable

Not only is PETG food safe, but it’s also recyclable. This translates to an improvement of waste management in the environment.

Durable

PETG is recognized for its durability and impact resistance compared to other materials such as ceramics.

Cost-effective

PETG food containers are more affordable than the much-adored glass malware or microwave-safe dishes everyone so desires.

Easily Decorated

Despite being transparent, PETG is easily decorated to create unique appearances and effects.

Odorless Emissions

Have you ever placed hot food or drinks in a plate/ cup and smelt some kind of odor from the material used?

Well, 3D printed PETG is odorless, even when handling hot beverages or edibles, making it convenient for your home.

What the Future Holds for PETG?

While there seems to be a prominent future for PETG in the global food industry, there are also concerns that need to be addressed.

For these products to be wholly accepted as a reliable option for many households, the matter of its food safety needs to be addressed.

All products available in the market should be FDA approved. Manufacturers should be supervised to ensure any additives used in the printing process don’t threaten the consumer.

Conclusion

Polyethylene terephthalate glycol is a versatile material that many manufacturers find more reliable than others.

As 3D printing takes on a broader field of food-safe applications, certain brands of PETG are expected to dominate many industries in the future.

Recommended Reading

Are 3D Printer Nozzles Interchangeable?

Are 3D printer nozzles interchangeable? Nowadays, 3D printers support interchangeable nozzles. But, 3D printing nozzles aren't universal.

PETG vs ABS. What Should I Choose?

We'll explore PETG vs ABS, answering each question you might have, but first, read our detailed description to understand what these two filaments are.

How To Remove 3D Print Supports From The Bed

So how to remove 3D print supports from your 3D printer build plate? Before removing support, the print bed should be allowed to cool for some time.