There are various ways of waterproofing 3D prints. You can print thick layers, use water-resistant filaments, use a wider extruder, increase the perimeters, use high-temperature settings, print less complicated models, and post-process.

As an Amazon Associate, I earn from qualifying purchases. If you make a purchase after clicking on a link I may earn a small commission at no extra cost to you.

Stick around to find out the processes through this guide.

Quick Navigation

How Can I Make My 3D Printer Waterproof?

Having a top-quality 3D printer enclosure is one method to ensure your machine is not only safe from accidental water spillage but is also beneficial for other reasons. You can protect your 3D printers from dust, and winds and have better heat preservation with enclosures.

Heat maintenance ensures there is an excellent environment to promote the adhesion of your 3D prints, which improves their water resistance.

Other measures you can take to enhance your printer’s ability to develop waterproof parts include:

- Printing at the highest temperature settings that won’t cause imperfections

- Getting 3D printers with large nozzles

- Getting a printer compatible with water-resistant filaments

How Do You Waterproof PLA Prints?

One means to have waterproof PLA prints is to apply wax. It is readily available and used in many applications besides waterproofing prints, for instance, coating carbide tools with titanium aluminum nitride to enhance sturdiness.

No 3D prints are similar, as you’ll make objects for diverse purposes. So, determine the appropriate place to coat wax and where not to if you want to save your expenses.

Another option is by using a fixative spray paint which will also improve the UV resistance of your PLA print. Curing with a solution during post-processing can also help improve water-tightness.

We’ll cover more on how to waterproof PLA objects among other 3D prints later in this article.

How Long Will PLA Last in Water?

PLA decomposes in water in as little as one-and-a-half to three months which is about four times faster than PET-based bags. But you require the right conditions to achieve such results. Its degradation is a bit retarded in ambient temperatures.

According to a 2017 study, PLA had not degraded after a year in saltwater at 25 °C in seawater. Therefore, PLA degrades poorly in household composts and landfills. However, it decomposes better in hotter industrial composts.

Can PLA Prints Get Wet?

This bioplastic material comes from plants like potatoes, rice, and corn. If you leave PLA in the open, it takes several months to decompose to form moisture, carbon dioxide, and methane.

Since PLA breaks down quickly, it shows that it gets wet by absorbing moisture in the environment to speed up degradation.

Tips for 3D Printing Waterproof Parts

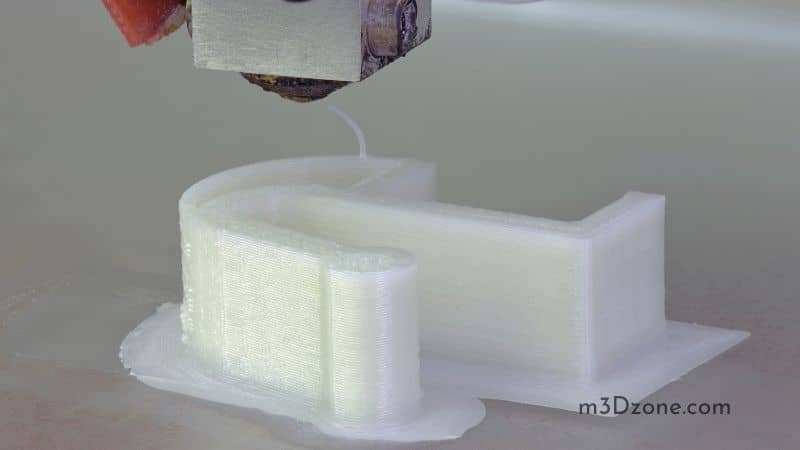

3D printing creates products layer by layer, typically hollow. Through these gaps, liquids can penetrate and escape the part. Improving the waterproofing of your model allows you to use it as a container and makes it resistant to weather action.

Let’s look at the techniques to solve this issue in the section below.

Waterproofing Your 3D Prints

Here are the ten best methods for waterproofing your 3D prints.

1. Using Water-Resistant Materials

Various 3D printing filaments come in handy when creating water-resistant or waterproof 3D models. Here are some of them:

-

PP (Polypropylene)

PP is a popular choice for people who make bottles, containers, food packaging, and more. While other materials absorb moisture, Polypropylene is hydrophobic, making it repel water.

This plastic (see it on Amazon) is a suitable selection for anyone in need of a watertight print. It has good interlayer adhesion and flexibility. For this reason, it doesn’t produce many holes or gaps between its layers during printing.

Besides being waterproof, it also resists other substances, for instance, aggressive chemicals like organic solvents, alkali, and acids.

-

PP GF30

PP GF30 is both waterproof and resistant to aggressive environmental conditions, including UV, high heat, and chemicals.

Its difference from PP is an additional 30% glass fiber. The reinforced glass fiber ensures this filament remains water-resistant and lightweight while improving its rigidity and strength. PP GF30 is a popular choice for printing things in the aerospace industry.

-

PET-G (Polyethylene Terephthalate Glycol-Modified)

PET-G is water-resistant and also a suitable choice for people who want an easy-to-print material. Its ease of use is similar to PLA, although it has sturdier technical properties.

2. Increasing Wall Thickness

Increasing the layer height slightly can lower leakages by minimizing the interfaces of your 3D print.

3. Over Extrude

You can do this by adjusting your slicer settings. Lower your print speed while increasing the extrusion multiplier. Using slightly coarser extrusions ensures your filament merges better with the already printed layers.

However, over-extruding can lead to lower design quality.

4. Increasing the Perimeters

This is a great way to waterproof your 3D print without immensely affecting its design. Adding the perimeters or shells around your 3D model offers extra protection and space between the print and water.

5. Print Less Complicated Models

Creating less complex geometries may not always be your first choice but still an excellent way to waterproof your 3D print. Designs with sharp corners, overhangs, and intricate lines and details have more chances of error in layer adhesion and gaps.

6. Hot Printing

Have your layers as hot as possible to improve layer adhesion, and minimize fluids passing through the gaps. Try shutting your coating fan to make layers stick better, provided you don’t mess the project.

7. Using Wide Nozzles

The broader and higher your layers are, the lesser the interfaces between for fluid to pass through. Printing with a wide nozzle (see it on Amazon) produces your model faster and leaves thicker strands of material. As a result, the former layer is much hotter upon the deposition of the new layer.

Using a nozzle diameter of about 0.6mm or 0.8mm is an excellent choice to improve your print’s imperviousness.

8. Epoxy Resin Coating

Coating your print with epoxy resin is another method to make your print waterproof.

Epoxy is also suitable for gluing and smoothening finished products. Something to consider here is the purpose of your 3D objects. The best solution is to go for food-safe epoxies.

9. Use a Solvent

Whether using acetone on ABS or chloroform (acetone work too) on PLA, solvent application smoothes products. It binds the layers together, therefore enhancing the water-tightness.

10. Using Wax to Waterproof 3D Prints

Wax is another excellent coating you can use on your 3D print besides epoxy.

- First, clean your 3D part from dust and all residue.

- Melt your wax using a heat gun or other heat source. Make sure the wax remains warm as you continue brushing it on your 3D-printed objects.

- Leave the wax to cool, then scrape off the excess wax.

Impressively, you only require a small amount of wax to make your 3D object watertight. Unless you have a large object consisting of many 3D printed parts, a ¼ cup can do the job.

Related: Wax 3D Printing. Is It Possible?

Is PLA Water-Resistant?

PLA isn’t water-resistant. Since most of its ingredients are organic, it absorbs moisture. That doesn’t mean it degrades as fast as organic components. Regardless, it decomposes at a faster rate than other 3D printing materials like PETG and PP.

Final Thoughts

The best approach to making a waterproof container is by using water-resistant filament. Nevertheless, combining the different techniques discussed above can help you get a sturdy waterproof 3D object.

Recommended Reading

Educational 3D Printing. 3D Printers in Education.

In short educational 3D printing refers to using the new technologies in 3D printing explicitly designed to help students learn. Let's find out how!

What Materials Are Used in 3D Printing?

Plastics, metals, and ceramics can produce a diverse range of products. Did you know even soybean oil, chocolate, and wet paper can also make 3D prints?

What Is SLS 3D Printing? Selective Laser Sintering Guide.

What is SLS 3D printing? SLS technology uses a high-power laser to sinter small polymer powder particles into a solid structure 3D model. Let's dive into it!