3D printed parts interior (fill) and exterior (shell) are distinct. While you can print hollow or solid inner sides, the wall is solely solid.

The shell refers to the top, bottom layers, and walls. It contributes to the model’s mechanical properties like tensile strength and fatigue limit.

Quick Navigation

- What Is Wall Thickness 3D Printing?

- How Thick Should a Wall Be 3D Printed?

- Recommended Wall Thickness for 3D Printing (TABLE)

- Minimum Wall Thickness vs Resolution

- How to Calculate The Right Wall Thickness for Your 3D Printed Model

- How to Get the Perfect Wall/Shell Thickness Settings

- 3D Printing Wall Thickness Vs Infill

- Parting Shot

The 3D parts walls comprise the vertical outside region that makes up the prints’ height. One of the most significant factors to consider in your 3D printing design is wall thickness.

So, how do you design a perfect wall thickness? Worry not! We’ve got you covered!

This article provides you with all the crucial details and guidelines you need to understand and develop perfect wall thickness settings for your prints. Read on!

What Is Wall Thickness 3D Printing?

Wall thickness is the distance between one side of your 3D part and its opposite surface. It’s the smallest possible thickness your model should have without failing in functionality.

And the correct assigning of your model’s wall width is essential when dealing with wall thickness issues.

Why? Because inappropriate wall thickness is the primary cause of problems in the 3D industry.

The thickness of your parts depends on factors such as overall design, size, and the material used. Below are guidelines to consider for your wall thickness.

Maximum Wall Thickness for 3D Printing

Maximum wall thickness is ideal for heavy materials like metal because they tend to exert inward stress.

Nonetheless, these walls aren’t printable. For that reason, make your models hollow and create outlet holes to channel out the powder.

Minimum Wall Thickness for 3D Printing

The minimum wall thickness for strong materials like stainless steel can be as low as 0.3 mm. The thickness depends on your 3D model’s design and structure.

For example, in the case of high-detailed 5mm2 stainless steel, the wall thickness has to be 0.3mm.

How Thick Should a Wall Be 3D Printed?

Generally, 0.8mm is the default standard 3D print wall thickness for minimal strength. For the best wall thickness, about 1.6mm would do. Even so, have a minimum of three walls for more durability.

Furthermore, the default value of the slicer may be appropriate in most cases.

Basic Guidelines for Setting Your Wall Thickness Values

However, adhere to the following guidelines if you wish to set your thickness values:

- Use your nozzle diameter multiple as it’s the most effective for printing full-size walls.

- Likewise, use your layer height multiple for the full-size layers for the best results of your top and bottom thickness.

- For more durable parts, use larger wall thickness values such as 2-3mm and 1.6-2mm top and bottom thickness.

- For less strong display-oriented models, 0.4mm wall thickness and 0.2-0.8mm top and bottom thickness will do.

Recommended Wall Thickness for 3D Printing (TABLE)

3D printed parts have specific thinness limitations that they can’t go under. The table below shows the recommended minimum wall thickness for the particular material versus the absolute minimum thickness of the same.

| Recommended Wall Thickness | ||||||||

|---|---|---|---|---|---|---|---|---|

| Material | PLA | ABS | NYLON | VEROWHITE | TRANSPARENT | ABS-LIKE | RUBBER-LIKE | VISICLEAR |

| Recommended Minimum Thickness (mm) | 1.5 | 1.5 | 1.5 | 1.0 | 1.0 | 1.0 | 2.0 | 1.0 |

| Absolute Minimum Thickness (mm) | 0.8 | 0.8 | 0.8 | 0.6 | 0.6 | 0.6 | 0.8 | 0.6 |

Moreover, your choice of printing material is also a primary contributor to your breakthrough.

Also, it’s essential to note that no 3D printing can take place below the absolute minimum!

Minimum Wall Thickness vs Resolution

There seems to be a very thin line between the two elements. However, the two aren’t similar!

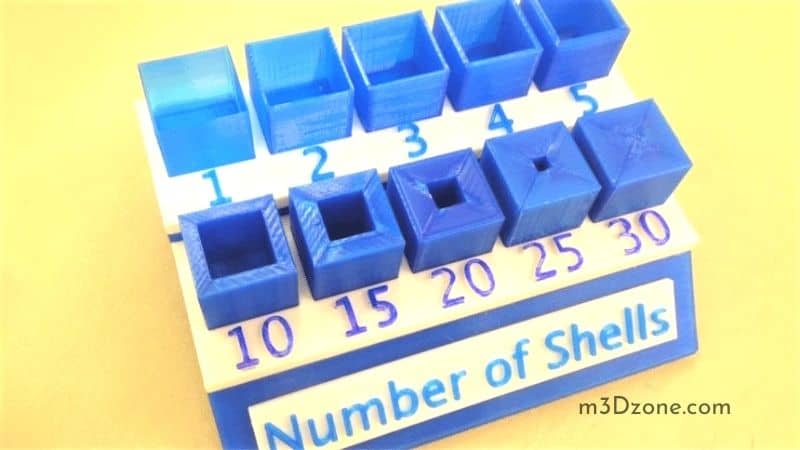

Minimum wall thickness indicates the smallest width of the shell that your printer can produce without collapsing due to being heavy. The resolution, on the other hand, determines the curvature’s smoothness.

Low resolution indicates roughness, while high resolution shows the opposite.

Resolution is some kind of dimensional tolerance as it shows a part’s accurate design suitable for printing. It shows a design’s preciseness and fine details with enough thickness to support structure for your shell thickness settings.

How to Calculate The Right Wall Thickness for Your 3D Printed Model

The usual way of calculating the proper wall thickness of your 3D printing part is using a value of your nozzle diameter’s multiple.

That way, you’re sure of not having gaps or imperfections on your prints. For instance, if you have a 0.4mm nozzle diameter, you may have your wall thickness as 0.4mm, 0.8mm, 1.2mm, and such other multiples.

The wall thickness of regular, moderately strong parts ranges between 0.8mm and 1.6mm with 3 to 4 wall lines. The top and bottom thickness are about 0.8mm to 1.2mm. Depending on the wall line count setting, have 4 to 6 layers.

When dealing with a weaker, brittle material, the effect on the overall wall thickness can be positive or negative. You need to be conversant with the recommended minimum wall thickness.

For the overall shell thickness adjustment, change the layer thickness. For example, with a 0.8mm wall thickness and a 4 wall line count, you’ll have a 3.2mm wall thickness.

The general principle of 3D printed parts thickness should be 0.8mm for 2mm to 3mm nozzle diameters. The size depends on your 3D printer. Furthermore, the default value of your slicer will suit your case in most cases.

How to Get the Perfect Wall/Shell Thickness Settings

Getting a perfect wall/shell thickness is relative! We don’t have a specific wall thickness that will work best for your 3D parts. Nevertheless, you want to maintain the standard range of 0.8mm-2mm.

Since 3D printed parts have diverse functionalities and purposes, it’s advisable to first determine your print’s use. You can then proceed to get its ideal wall thickness. While some parts are for decoration and looks, others fall under load and physical bearing.

For example, when printing a vase, durability isn’t a major factor to consider for its use. Hence, you only need a minimum thickness of your wall.

On the contrary, for a wall mount bracket, you need suitable material, infill, and several wall lines to build substantial parts.

Basically, you determine the perfect wall thickness using a trial-and-error strategy through gaining experience. Once you understand which wall thickness works best for specific parts, it becomes easy moving forward!

Additional Factors to Consider When Selecting an Ideal Wall Thickness

Filament type

Knowing the type of your filament is an important consideration. The recommended wall thickness of usual filament materials like Nylon, ABS, and PLA is 1.5mm.

Even though most manufacturers may recommend a 0.8mm wall thickness, it isn’t applicable to all designs.

Support Structure

The presence of overhanging features exposes your designs to the risk of collapsing during printing. This happens when you try to strengthen them using thicker walls as they make them heavier.

In such a case. A good support system is your ideal remedy. The system ensures that the overhanging features won’t fail even with the minimum recommended wall thickness.

Thickness Adjacent Walls

Your part’s wall thickness should be more than 60% of the thickness of the wall adjacent. Why? Because your printing’s accumulated thermal stress can cause failure at any fragile point. Therefore, you need to maintain your prints’ wall thickness consistency.

Internal Radius Curves

Since your prints’ thermal stress accumulates around sharp edges when cooling, you may opt for rounded edges. This applies where your design can accommodate the adjustment.

Nevertheless, for some designs, you must use sharp edges. In such a case, curve the edges on the inside to reduce internal stress accumulation without deviating from your desired artistic.

3D Printing Wall Thickness Vs Infill

Although both wall thickness and infill increase the strength of your parts, use wall thickness for durability purposes.

Your model’s strength level and infill percentage are inversely proportional. For instance, a 0% infill and 4mm thick wall are more durable than a 100% and 0.8mm thick wall model.

In a nutshell, your 3D models are less likely to break and more durable when the wall thickness is strong. However, for best results, combine the high thickness level with a high infill percentage.

Even if both factors consume more materials, your wall thickness uses fewer materials than the strength it provides.

Parting Shot

Your 3D print wall thickness is one of the essential print parameters in designing your parts. If you design too thick parts, they’ll be more expensive to produce, consume more printing time, and may even end up cracking.

For very thin walls, the model may be non-functional or warp up when printing. Also, your parts’ cost of production goes up due to the design rework.

Hence, you should work with the minimum recommended thickness to ensure the durability of your models.

Recommended Reading

Is PLA Recyclable? Recycle Your 3D Printer Filament

Is PLA recyclable? Yes! You can recycle PLA plastic filament. BUT don't mix it with other types of everyday plastic because its melting point remains lower...

Does 3D Printing Smell?

Does 3D printing smell? Yes, 3D printing smells. The stench is produced since 3D printers use heating technology to melt filament materials. Read more inside!

What Is a 3D Printer Operator?

So, what is a 3D printer operator or technician? A 3D printer operator is a competent individual with technical and creative skills in additive manufacturing.