If you want to dry your 3D printer filament but don’t know how to do it, don’t stress!

As an Amazon Associate, I earn from qualifying purchases. If you make a purchase after clicking on a link I may earn a small commission at no extra cost to you.

You can throw your plastic filament in the oven and set the temperature below the glass transition temperature of the plastic. Now, put your oven on and leave it for 4 to 6 hours. Moisture will cook out sufficiently under this period.

Remember, the longer you leave 3D printing filament in the hot oven, the dryer it will get. However, you’re called upon to be careful not to over-dry it. Doing so may result in the plastic burning up due to overheating.

Quick Navigation

Alternatively, you may use a machine known as a filament dryer to dry your moist filaments. It functions by dehydrating filament moisture leaving it dry. Dry filaments guarantee better quality print whereas, moisture filament ultimately compromises print quality.

How Do You Identify Wet 3D Printer Filament?

Dry 3d printer filament help in the production of high-quality prints. So, before you learn how to dry filament, the next concern would be to identify a wet filament to dry it up.

The 3D printing industry boasts a variety of printer filaments. All these 3d printing filaments absorb moisture at different rates. Therefore, it will serve you well if you can identify a wet filament in good time.

Listed herein, find some obvious signs that show you have wet filaments in your custody.

- Popping/Cracking sounds when extruding.

- Highly reduced part strength and layer adhesion.

- Uneven extrusion lines.

- Severe stringing, blobbing, or oozing.

- Visible textured surfaces on print.

You need to dry your filament once you realize it’s wet to guarantee excellent quality 3D prints.

How Do You Dry Filaments at Home?

Let’s see what options do you have for drying your filaments at home:

-

Oven

After identifying a wet filament, proceed to dry it out. An oven becomes one of the readily available types of equipment you can use to dry it up.

You can only use ovens that allow control of temperature to dry the filament. Now, set oven temperature below the glass transition temperature. Check oven thermostat temperature accuracy before putting filaments inside the oven.

Use a regular thermometer inside the oven after pre-heating to confirm the temperature accuracy. In case you notice inconsistencies in temperature, adjust to eliminate them.

Only put your filament in the oven once sure of the temperature accuracy. When using PLA filament, you can quickly destroy your filament if the oven temperature shoots up abruptly, even for a few minutes.

-

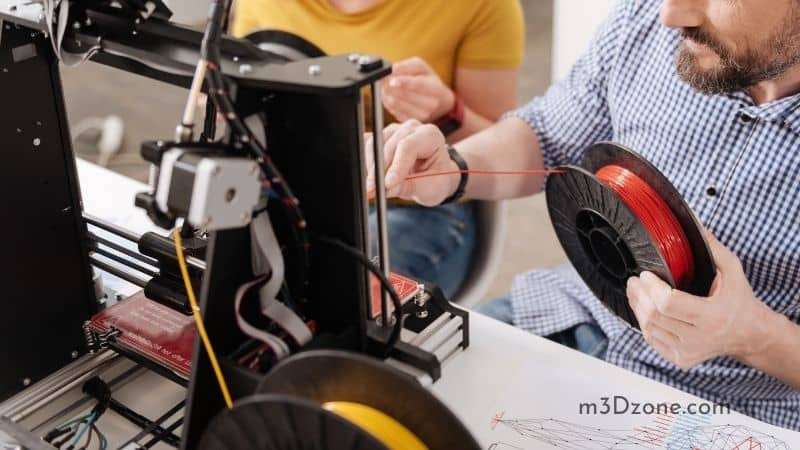

Filament Dryer Machines

Filament dryers are machines tailor-made for use in drying filaments of different natures. These user-friendly devices help in drying up filaments hence helping improve print quality.

To operate your dryer, put your filament inside and select the correct settings. Now, let the dryer work on your filament for a pre-determined time. After that, retrieve your dry filament from your dryer.

In some cases, the filament dryer works alongside the 3D printers allowing you to save time by simultaneously drying the filaments as printing goes on.

-

Food Dehydrator

You may opt to use a food dehydrator (check at Amazon) as another way of drying out spools of filament at home. Initially designed for drying up fruits, food dehydrators may be repurposed for drying up filaments.

Moreso, if you lack an oven at home, converting a food dehydrator into a filament dryer is a good idea.

Food dehydrators work under much lower temperatures than ovens and can quickly dry PLA filaments with low glass transition temperatures.

The only notable drawback is that it has a low capacity that can only accommodate two spools of filament at a time.

What Temperature Does Filament Dry At?

After absorbing moisture from the air, water molecules bound with the polymer chain of the filament. The filament dryer uses heat to move filament molecules vigorously. Therefore, weakening and breaking the water molecule bond from the polymer chains.

Heating permits water molecules to move freely. Thus airflow carries heat to the filament and carries the freed water molecules away. This movement enables the filaments to dry up.

Temperature Different Filaments Dry AT

| Filament Type | ℃ | ℉ |

| ABS | 65℃ | 149℉ |

| PETG | 65℃ | 149℉ |

| NYLON | 70℃ | 158℉ |

| DESICCANT | 65℃ | 149℉ |

| PVA | 45℃ | 113℉ |

| TPU/TPE | 55℃ | 131℉ |

| ASA | 60℃ | 140℉ |

| PP | 55℃ | 131℉ |

| HIPS | 60℃ | 140℉ |

| PC | 70℃ | 158℉ |

| PEEK | 70℃ | 158℉ |

(Filament Type Temperature In ℃ & ℉)

Related: At what temperature does nylon dry during 3D printing?

How Do I Keep My 3D Filament Dry?

Moisture and humidity remain the greatest enemies of 3D printing filament worldwide. Moist and wet filaments result in the manufacturing of low-quality print. On the contrary, dry filament means the production of high-quality prints.

Therefore, ensuring your 3D filament spools remain dry needs to be given proper attention. Don’t forget that most thermoplastics used in 3D printing are hygroscopic. , they have a high moisture uptake, therefore absorbing water from the surroundings if left unprotected.

a) Vacuum Bags

Vacuum bags (check at Amazon), the expensive plastic casing for individual spools of filament, works perfectly to ensure that plastic filaments remain dry when stored in them.

You may avoid using the ordinary Ziploc plastic bag as a storage device for your filament, as it never gets out all the air ultimately.

b) Anti-Humidity Box

You may construct an anti-humidity box to keep your spool of filaments dry (see the easy DIY project). Fix the box on your rooftop to deter your filament drying up process. The anti-humidity box keeps moisture away from your filament.

c) Silica Gel

Silica Gel products (check at Amazon) work well to keep moisture away from your 3D plastic filament material.

Drying filaments remain important as both PLA and ABS filaments material absorb moisture from the surrounding. Silica Gel comes in handy to keep water away from these filament materials.

It explains why you may get a Silica Gel pack for free when buying plastic filament material.

d) General Tips Of Keeping Filament Material Dry

- Endeavor to use litmus strips to check humidity: It works faster compared to using color-changing desiccants.

- Always remove filament material upon finishing printing.

- 3D print your spool holder to protect your filament layer lines from moisture.

- Construct your own “dry box” by searching websites for helpful information.

- Plug dehumidifiers overnight when you realize your filament are wet.

How to Dry PETG Filament

PETG filament material has hygroscopic qualities. Therefore, its tendency to absorb moisture from the air remains high. Humidity and water are known enemies of filaments because they impact negatively on print quality.

Luckily, drying up PETG filament can be done at a meager cost, almost freely. Now, PETG filament (check at Amazon) dries up at 65℃ ( 149℉), so pre-heat your oven to 65℃.

After confirming using your thermometer, there are no inconsistencies between the oven temperature and the stipulated temperature; put your PETG filament in the oven.

Leave the filament inside the oven for about 4-6 hours as the oven works on it.

Finally, remove and place the filament in an airtight container with a desiccant. A 5gallon bucket with a tight lid may serve you well for filament storage, ensuring it remains dry.

Alternatively, you may use a filament dryer. Just set the requisite temperature for the PETG filament at 65℃ ( 149℉) and let the filament dryer work on it for a couple of hours. Remove the dry filament, and you will be ready to print quality 3D models.

Some filament dryers have small holes that allow the filament to pass into the Bowden tube (check at Amazon). This tube enables filaments to stay dry as printing proceeds.

However, these types of dryers remain pretty expensive in the market and are primarily affordable to professionals.

Also, related: Key features of PCTG

Is PETG Moisture-Sensitive?

PETG, a thermoplastic polyester, delivers significant chemical resistance, durability, and formability rarely marched by most plastic filaments. That’s why it’s fast-growing up as a favorite to many 3D printing hobbyists.

Some filaments are more sensitive to water than their counterparts, and PETG filament belongs in the middle of the spectrum. Thus, PETG filament doesn’t absorb as much water as other plastic filaments.

It means you may only need to keep your PETG filaments in low-humidity places to safeguard them from acquiring harmful moisture. 30% may be the ideal relative humidity for keeping PETG filaments.

It sounds great for people living in Nevada, Arizona, New Mexico, and Colorado in the US, places with low humidity levels.

How to Dry ABS Filament

One of the most recognizable 3D printing materials, the ABS filament absorbs water and will need drying up to manufacture quality prints. You may use an ordinary home oven or a filament dryer to dry the ABS filaments.

Consider the glass transition temperatures before you start to dry the filament in either the oven or the filament dryer. Always set to dry ABS at a set temperature of 80-85℃ and dry it up for at least four hours running.

The target temperature remains one of the critical steps to adhere to in any method you may use for drying the ABS filament (check at Amazon). It ensures you don’t destroy the filament as you dry it up.

Sidenote: Remove the spool of printing material once printing is complete.

Does PLA Need a Dry Box?

Manufacturers of PLA filaments pages PLA filament life at 2-3 years. However, exposure to heat and humidity can quickly reduce this shelf life.

PLA filament, being hygroscopic, will readily absorb moisture if left unprotected. That can lead to poor-quality 3D printed models. For this reason, protecting the filament through proper storage becomes a popular solution.

Leaving out open spools of PLA filaments is a bad idea, especially when left open in humid conditions. Proper storage in a cool, dry, and dark place is ideal.

However, using the dry box as a storage tool comes in handy and has become one of the most popular solutions 3D printing hobbyists use to shield PLA filaments from moisture and water.

Conclusion

Moisture and water remain proven enemies of 3D printing filaments worldwide. As a 3D technology hobbyist, you need information on how harmful humidity can be to filaments and the available solutions to this challenge.

The article serves as a good guide providing the information you may need to dry wet filaments. We have stated the exact methods available for drying different types of filaments.

Recommended Reading

Food Safe Coating and Sealants for 3D Prints

Food safe coating for 3D prints. What are they? A food-safe coating is critical for manufacturing 3D models ensuring that the food they handle remains safe.

3D Printing vs Injection Molding

3D printing technologies use an additive manufacturing process. while injection molding involves adding molten material into a mold cavity. Let's dive into it!

3D Printer vs. Laser Cutter

A laser cutter works by cutting away material to create an object vs a 3D printer works through an additive process where objects are created by adding layers.