The 3D printing technology offers two types of 3D printing technology. These are the Fused Deposition Modelling (FDM) and the Stereolithography (SLA) or the Digital Light Processing (DLP).

Also, each of these technologies uses a distinct type of 3D printer for 3D printing. Interestingly, both use plastic, although in different forms.

Quick Navigation

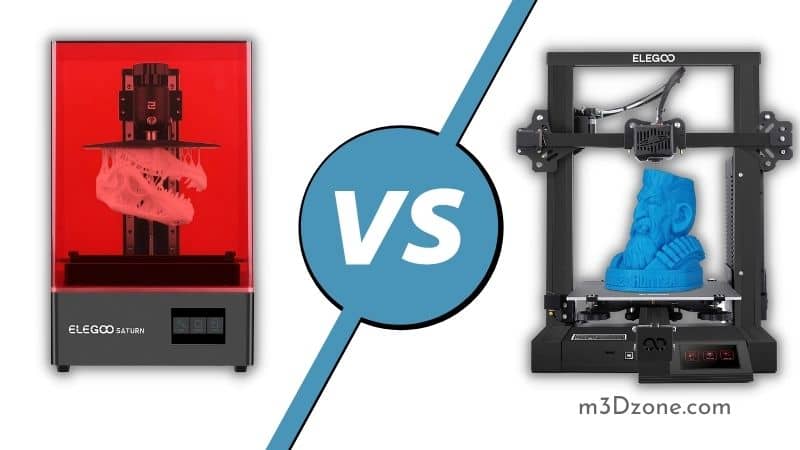

Resin vs Filament 3D Printer

The SLA/DLP printers use liquid resin, while the FDM printers use filament for 3D printing. The two materials have different mechanical properties, features, pros, and cons.

This article will take you through issues surrounding the 3D resin printers and filament printers, the technology they use, and how they work so that you will be in a better position to decide which one to use depending on your printing needs.

SLA/DLP vs FDM Explained

In resin 3D printing, the most common and popular printing processes remain Stereolithography (SLA) and Digital Light Processing (DLP). A resin printer produces resin print that remains highly rated in quality.

SLA Printer Technology

Desktop SLA 3D printers have features that include a resin tank with a transparent base and a non-stick surface. The non-stick surface provides a layer for the liquid plastic resin to cure as it solidifies into a physical 3D object.

Furthermore, it provides for ease of detachment of the formed layer from the surface.

Resin Printing and How the SLA 3D Printer Works

Resin refers to a thermoset material used in SLA 3D printing as an important plastic for manufacturing the 3D models.

SLA uses the additive manufacturing process. Also, the technology can be referred to as resin 3D printing. Notably, the resin printer uses a light source, build platform or print bed, and a resin tank.

To manufacture resin-printed objects, the machine uses a light source in the form of a laser or a projector to cure liquid resin into hardened plastic models.

SLA Printing Process

When you expose SLA resin to a certain amount of UV light, a chemical process begins where shorter molecular chains join each other, polymerizing monomer and oligomers making a solid or flexible object.

Then you can use isopropyl alcohol to help you remove the finished model from the build plate as it adds layer adhesion.

Types of Resin

Manufacturers produce different resin printing packs that can be used by other SLA 3D printers or depending on your resin printing preferences.

- The Standard Resin

- The Tough Resin

- Clear Resin

- The Castable Resin

Advantages of Resin as a Printing Material

- Prints top quality 3D objects

- Manufactures strong pattern like structures

- It fastens the printing process

- It enjoys many uses and applications across different industries

- You can drain and save unused resin for future use

- Resin3D prints offer an attractive appearance

Disadvantages of Using Resin as a Printing Material

- Too smelly

- Likely to spill

- It needs light to cure

- It would help if you had gloves to handle resin

- Draining uncured resin and removing the model can take time

- Not easy to use

- You need to cure, wash, and dry completed resin 3D models

- Both machine and resin remain costly

Application of Resin 3D Printing

Resin 3D printing remains popular while manufacturing prints of extreme quality. Therefore, the high-quality resin prints feature makes resin quite attractive when creating jewelry and figurines.

The FDM Printing Technology

The Fused Deposition Modeling (FDM) technology uses special 3D printers that use thermoplastic filaments to create solid, durable and parts that remain dimensionally stable.

Additionally, it manufactures 3D quality prints with a high level of accuracy and repeatability.

The technology remains anchored on using a 3D filament printer to heat the plastic until it melts.

Then, the molten filaments are deposited layer upon layer on a build platform using the printer nozzle until the printer achieves the desired design.

How 3D FDM Printers Work

FDM printing technology refers to the technology that enables the FDM 3D printer nozzle to move vertically and horizontally while the extrusion nozzle deposits layers of molten thermoplastic to create a 3D object layer after layer.

After the printer nozzle completes the first layer, the printer automatically lowers down the nozzle to print the next layer onto the previous layer. So, the printing process will continue in the same manner, layer after layer, until the printer creates the desired design.

You can then proceed to remove the support material from the print object to get your desired print.

Filament Printing

The specialized 3D printer used in FDM printing technology uses thermoplastic filaments. Also, 3D printing filaments can be found in different types and brands.

Types of 3D filaments used in FDM 3D printing:

Advantages of Using FDM Printing Technology

- Economical

- Re-usable filament

- Enables cloud serving 3D printing

- Not a complex process

- It offers a variety of material choices

- Portable

- Manufactures compact design

Disadvantages of Using FDM Printing Technology

- Manufactures products with a rough surface

- The Challenge of warping remains common

- Persistent nozzle clogging

- It takes a long time to print the layer

- Layer adhesion challenges

- Manufactures models with weak strength

- You need to conduct frequent bed calibration

Application of FDM 3D printing

FDM, also referred to in some quarters as Fused Filament Fabrication (FFF), remains one of the most used and popular technology in the additive manufacturing technology family.

Major applications associated with the FDM technology;

- Prototypes

- Prosthetics

- Gifting

- Industrial application

- Architecture

- Pre-surgical models

- Household items

DLP Printing Technology

DLP remains similar to SLA printing technology. Therefore, SLA and DLP share many similarities, with the only exception being how they use UV-light to print objects.

More importantly, DLP uses a digital projection surface as a light source, while the SLA uses lasers instead.

How Do Resin Printers Work?

The special resin 3D printers don’t use powder or even plastic filaments. Instead, they use resin for their 3D printing. Additionally, the SLA process takes place at the printer’s build plate.

The SLA 3D printer roller spreads a thin resin layer on the platform. Thus, as the resin remains in liquid form, it spreads quickly to cover the whole platform. The resin spread enables layers to enjoy a consistent level of thickness.

The resin has mechanical properties that make it sensitive to UV light. The first thing that laser does is outline the print design onto the resin layer.

Then, the laser hardens the areas it touches, leaving the new parts still in liquid form. Also, the printer slightly lowers the model so that the roller can spread out a new layer.

The SLA printing process repeats these two steps over and over until it creates a new design. Notably, the laser keeps solidifying the areas it touches, making them part of the design print.

This additive manufacturing process proceeds until the printer finishes printing the desired 3D model.

Resin vs Filament Cost

As a 3D printer hobbyist, you need to consider other factors when buying a 3D printer than the printer cost only. In essence, it would help if you thought about the budget for printer consumables.

The filament or the resin costs come to play as you decide on the 3D printer to purchase. Also, printer accessory costs and the demand time remain the other considerations informing your printer purchase decision.

Costs Comparison Between Resin and Filament

If you compare the cost of filament printers and resin printers, the filament comes out on top as the cheapest and most affordable printer you can find in the 3D printer industry market.

Moreover, it cuts across all the cost aspects of operating a 3D printer and the printing process.

For beginners, SLA/DLP 3D printers remain pretty expensive in the 3D printer market for the simple reason that they are few. On the contrary, the FDM 3D printers enjoy widespread use among professionals and 3D enthusiasts.

Additionally, the FDM 3D printer cost has remained on a downward trajectory over the past years. 3D printer costs depend on the printer brand and the functionalities it can offer. Though, generally, you can find affordable FDM 3D printers at as low as below $200.

The same can not be said of the SLA/DPL 3D printer costs.

The other factor you need to look at remains the printer consumables and upkeep costs. Again, the FDM tops the SLA printer.

FDM filament spools cost as low as $25 or less. You may also be forced to replace the printer nozzle because of conducting regular maintenance exercises frequently.

In contrast, you will need to replace the resin and the resin tank more regularly. Furthermore, a resin tank may cost you approximately $40, and a litter of resin costs around $80.

In the final analysis, resin printers will cost you far more than the FDM printers. So, you may want to stretch your dollar by 3D printing using FDM.

Is Resin Stronger Than Filament?

No, resin remains comparably weaker to the FDM Filament. Although Resin 3D print can be more robust with exceptional premium brands, the mechanical properties of the filament make it far stronger between the two materials.

Polycarbonate remains one of the most robust FDM filaments, with a tensile strength of 9800 PSi.

Also, Formlabs Tough Resin, one of the most formidable resin premium brands, whitens faster compared to the Polycarbonate filament at a tensile strength of 8080 PSi.

Additionally, most popular resins are brittle compared to filaments that remain pretty robust.

It tells the reason why manufacturing companies prefer to use the FDM technology to SLA/DPL technology when they want to create strong and durable parts capable of withstanding heavy use over time.

How Strong Is 3D Printed Resin?

The SLA 3D printing technology prints models of the highest quality that are detailed and have and a beautiful surface finish.

However, when you think of printing challenging, durable, and functional parts, you may not think highly of the SLA but the FDM technology because most standard resins remain brittle to the other printing materials like the filament.

The 3D printing materials recommended for stressed parts and outdoor use need to be tough and enjoy a high tensile strength, which lacks in resin.

Nonetheless, SLA introduced formidable resin brands to mitigate the lack of strength in resin with some level of success. Furthermore, studies concluded that some more rigid resins might be stronger compared to the standard resin.

This higher tensile strength enables it to print more rigid parts that previously would be manufactured by the FDM filament only.

Conclusion

The article elaborated pertinent issues that surround the SLA/DPL resin 3D printing and the FDM filament 3D printing.

Comparing these two 3D printing materials in terms of tensile strength, material cost, and application, provides valuable information for 3D printing hobbyists keen on purchasing either material.

More importantly, the discussion on how both the SPL and the FDM printers work helps you to understand how the 3D printing world works.

Recommended Reading

How to Fix PETG Corners Lifting in 9 Easy Steps

PETG corners lifting issues? We got the solution for you. In just 9 easy steps you won't have this annoying problem anymore. Read on to find out more!

How to Create STL Files for 3D Printing

STL files are formed through Computer-Aided Modeling (CAM) programs. Check our full guide on how to create STL files for 3D printing the easy way.

Are 3D Printer Nozzles Interchangeable?

Are 3D printer nozzles interchangeable? Nowadays, 3D printers support interchangeable nozzles. But, 3D printing nozzles aren't universal.