Most 3D printing hobbyists find it tricky when a project calls for cutting plastic material. More so, cutting acrylic or polycarbonate into plastic sheets.

As an Amazon Associate, I earn from qualifying purchases. If you make a purchase after clicking on a link I may earn a small commission at no extra cost to you.

Little debate takes place among 3D printing enthusiasts when it comes to cutting wood. However, it becomes a different story when it comes to cutting plastic.

The question remains: How to cut ABS plastic?

For example, getting a perfect cut remains difficult as some plastics melt during the cutting process. As such, you need to take proper precautions during the entire plastic cutting session.

Quick Navigation

It’s common for a plastic surface to get scratches during this process, and you may need to buff the edge when you complete the project.

This article serves as a guide on how you can successfully engage in cutting ABS plastic, getting the best results every time.

What Is the Best Way to Cut ABS? How to Cut ABS Plastic?

ABS( Acrylonitrile Butadiene Styrene) is a thermoplastic that can easily be molded when heated and hardens when cooled. As such, it can take many forms and maintain its quality. ABS plastic material is used in numerous industries and among 3D printing hobbyists as well.

ABS plastic is used in manufacturing keys for the computer keyboard, power tools, refrigerators, car interior, and a wide range of building materials.

4 Different Methods for Cutting ABS Plastic Sheets

To cut ABS sheets, you will undoubtedly require power tools. But if you are working on a thin plastic sheet, you won’t need a power tool as you can cut it by scorching the piece using a penknife (check at Amazon).

Also, cutting plastic needs a lot of focus and precision. You will need to control the power tool to ensure that the plastic sheet remains stationary.

Alternatively, you may feed the plastic piece to the power tool or machine by maneuvering it in a straight line for straight cuts.

1. Cutting ABS Sheet Using a Plastic Cutter

If you want to cut an ABS plastic piece using a plastic cutter (check at Amazon) or a utility knife, you need to confirm that the plastic thickness is 1/8 of an inch. Otherwise, cutting plastic with a higher thickness than 1/8 inches using a plastic cutter will not work.

How to Use a Plastic Cutter and the Importance of the Straight Edge

- You need to lay the plastic piece on a prepared work surface; a flat, stable table can work perfectly for this purpose.

- The movement of the plastic sheet may compromise the cut quality. Therefore, you need to clamp it (check at Amazon) on the table to ensure it remains stationary.

- Then, mark the cutting line with a straight edge or a highlighter that will help you navigate the machine effectively to achieve your desired cut.

- Score the piece of plastic with a plastic cutter or knife. It would help if you did it repeatedly until you achieved a deep grove.

- Score the line at least halfway through the plastic, then flip the plastic sheet and repeat the same process on the opposite side

- Finally, snap off the part that is hanging off the surface.

2. Cutting ABS Plastic Using a Circular Saw

A handheld circular saw (check at Amazon) works best to make linear cuts on ABS plastic sheets larger than 1/8 inches thick.

How to Use a Circular Saw

- Mark the cutting line using a highlighter

- Mark the backside of the plastic sheet as well.

- Secure the plastic using a clamp; this fixes the material to the edge of your workplace, stopping any movement during cutting.

- Carefully saw the plastic material.

- The friction from the blades heats the plastic material, so give it time to cool down after cutting.

3. Cutting ABS Plastic Sheet Using a JigSaw

Circular saws remain some of the best tools for making straight cuts. On the contrary, if you want to make curved cuts go for a jigsaw (check at Amazon). A jigsaw provides better mobility which enables you to create curved cuts into the ABS plastic material.

How to Use a Jigsaw to Cut ABS Plastic

- Draw a cutline on the ABS plastic pipe or sheet

- Also, you can choose to drill holes along the guidelines.

- Clamp the plastic material firmly on the work surface

- Switch on the jigsaw and cut the plastic along the guideline

- For effective curve cutting, turn the jigsaw and keep it as steady as you can

4. Cutting ABS Plastic Using a Band Saw

To cut circular and linear plastic curves, you need to use a band saw (check at Amazon). Additionally, a band saw has a long ribbon-like blade that comes up through the table surface. This feature allows you to get the precise cut you desire from a thick ABS plastic.

Steps to Follow when Using a Band Saw to Cut ABS Plastic

- Mark the cutlines using a highlighter (check at Amazon)

- Set the height of the blade guard guide

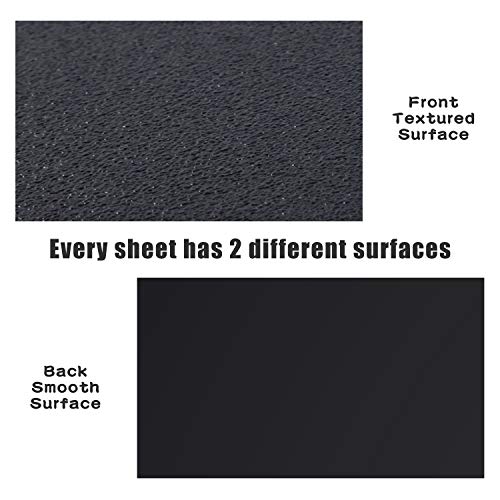

- Turn on the machine and feed the ABS sheet (check at Amazon) into the blade

- To create curves, steer the plastic sheet from behind as you push it through

What Do You Cut ABS With?

To cut ABS material, it will be helpful if you get one of these machines and power tools which will enable you to get your desired plastic cut:

- Utility knife

- Plastic cutter

- Circular saw

- Jigsaw

- Band saw

- Skill saw

- Air body saw (check at Amazon)

To cut a sheet of plastic, the choice of the machine matters. Additionally, manufacturers design each machine with features that enable you to get a specific cut. Both linear and circular cuts will require you to use a different type of machine and equipment.

How Do You Cut Thin ABS Plastic Without Cracking It?

Cutting hard ABS plastic without breaking it remains a difficult task. Luckily, you can use several techniques to ensure you cut the plastic piece without breaking it.

If the plastic is less than 1/2 an inch thick, you can use a string or a hot knife to cut the plastic material straight down the middle.

Additionally, you can use a circular saw to cut thicker plastics.

You can also drill small holes along the cut lines to prevent plastic breakage and make the piece easier to cut using other tools like the utility knife.

Step by Step Ways for Cutting ABS Plastic Without Breaking It

- Secure your plastic piece to your work surface with a clamp

- Grip a needle with a plier, then heat the needle with a lighter

- Use the hot needle to make a hole in the plastic

- Pass a cotton spool through the hole you have just made in the plastic

- Pull the thread to ensure it is tight, then use it the same way you would a saw. Thus, pull the string back and forth.

How to Cut Hard Plastic With a Saw Without Breaking It

There are a few types of saw that can cut plastic without breaking it. A saw is a good alternative for cutting a flat ABS plastic sheet or a thick piece of plastic.

So, you can use a hack saw, fine-toothed saw, circular saw, or a jigsaw to cut plastic material. More significantly, it will be helpful to avoid using saws or blades with more prominent teeth as they will easily chip and break the plastic creating a rough edge.

A saw or a sharp blade with fine teeth remains the best option to undertake whenever you want to avoid breakages when cutting plastic.

a) Using a Hot Knife for Cutting

You can use a soldering iron (check at Amazon) to cut through plastic, but first, you must flatten its tip. You may use a hammer or a mallet to flatten the soldering iron tip.

So, you can use the flatten tip to cut through the plastic as it minimizes plastic breakages.

b) Using a Drill to Cut Through Hard Plastic

You can use a drill (check at Amazon) to make holes along your cut line. Then, a fine-toothed saw or a utility knife can cut the remaining plastic.

How Do I Get Perfect ABS Prints?

To get a perfect print from ABS material (check at Amazon), you need to get your first layer right. Also, the first layer will determine the quality of the end product.

So, always calibrate your 3D printer build platform to avoid warping and lift-offs, negatively affecting ABS print quality.

Always check that the heated build platform remains hot. Still, ensure you set it at a temperature of 80-110 degrees Celsius.

This temperature range is ideal when printing with ABS material for the best print quality.

Stringing between separated parts is caused when the extruder leaks plastic amounts between the separated areas due to excessive temperatures in the build platform. More importantly, it diminishes the print quality and should be avoided by all means.

To achieve better ABS print quality, always ensure you use dry ABS filament. Moist filaments compromise the print quality.

Conclusion

The article provides information on how you can cut ABS plastic material. It provides different methods of cutting ABS so you may recognize their impact and how to take part in the process.

It also provides a list of tools used to cut ABS plastic to make it easier for you and information about how to get perfect ABS prints.

Recommended Reading

Top 8 Best 3D Printer Software for Mac Users (FREE Included)

You like 3D printing and have a Mac. What 3D printer software for Mac do you use? Let us guide you and show our top 8 picks. Some are free some not.

3D Printer Stepper Motor Useful Guide

3D printer stepper motor has been proven crucial in 3D printers. Come check our guide for the best stepper motors and drivers available now.

3D Printing Fume Extraction. Solutions & Safety Tips!

Let's dive into some 3D printing fume extraction methods. It will ensure 3D print safety devoid of contaminants from heated filaments from fumes.