3D printer extruder clicking is a common issue for 3D printers and can be caused by many different things.

As an Amazon Associate, I earn from qualifying purchases. If you make a purchase after clicking on a link I may earn a small commission at no extra cost to you.

If your printer has been extruding material, but you have noticed that it is now sticking in place or failing to extrude at all, there may be an issue with the stepper motor.

Quick Navigation

- What Is a 3D Printer Extruder?

- Why Does Your 3D Printer Extruder Clicking?

- How to Fix Your Extruder Stepper Motor

- Why Is My Extruder Clicking?

- The Importance of Regular Maintenance for Your 3d Printers

- Other Things to Consider When Troubleshooting This Issue

- Tips for Preventing the Problem From Happening Again in the Future

- Why Should You Be Concerned if Your 3D Printer Extruder Clicks

- Final Thoughts

This could be caused by several issues such as poor wiring connections in the circuit board or even low voltage power supply problems.

You should also check if any wires are loose near the stepper motor (check at Amazon). If they are loose, then you might need to solder these wires back onto their respective contacts.

In this blog post, we will go over some of the most popular causes of extruder clicking and how to fix them!

What Is a 3D Printer Extruder?

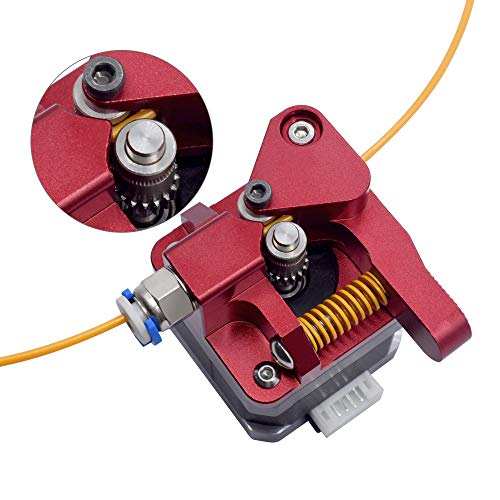

A 3D printer extruder is the part of your 3D printer that performs the task of turning plastic filament into a 3-dimensional object.

This process starts by melting and then squeezing out this molten polymer through small holes, or nozzles, in the hot end where it can cool down and harden before coming out onto your build plate as a 3D object.

Why Does Your 3D Printer Extruder Clicking?

This process of extruding the melted polymer is done using stepper motors, which are integrated into your 3D printer’s motherboard and control board settings to provide smooth operation and prevent sudden jerk movements.

This is what causes that clicking sound you might have heard when printing with some plastics or other materials.

The stepper motors also control the speed of extrusion and are calibrated to handle different filament types, speeds, and conditions.

They operate by rotating a threaded rod in precise increments that correspond with your 3D printer’s settings so they can produce smooth lines of plastic without any sudden movements or jerks.

This process is done at such high temperatures – around 230° C (450° F) for PLA; about 245°C (473°F) for ABS – that it will cause rapid wear on motor homing switches if not properly maintained.

This may result in an increased likelihood of clicking as you print because these rods have been worn down from overheating, which lowers their ability to stop rotation when instructed to do so.

To fix this, clean the homing switches (the metal contacts on either side of the motor) by wiping them down with an alcohol wipe or dry cloth. This will remove any dirt and flux from extruding, which would lessen its longevity.

After cleaning out these homing switches, they should resume their normal function to stop rotation when instructed to do so as they had been before clicking started occurring.

How to Fix Your Extruder Stepper Motor

The printer extruder clicking is an issue that can be solved easily. The problem occurs when one of the homing switches gets dirty and needs to be cleaned out.

If you’re experiencing 3D printer extrusion problems, don’t worry! There are a few things you need to do to troubleshoot your machine and identify what’s causing the click sound before it becomes too much:

- Check for any loose wires or cables near the stepper motor that could interfere with its operation. If any, try rewiring them so they won’t get caught on anything else during printing jobs. This should fix most cases where wire interference is happening due to improper wiring due to lack of experience.

If any wires still seem to be caught, try moving the extruder to see if it will free up enough space for 3D printing jobs without interference.

- Try unplugging and replugging in your stepper motor with a wire brush nearby so you can clean off any dirt or debris on its homing switch. This should fix most cases where dirty switches cause clicking due to lack of maintenance.

- If none of these steps works, check your power supply unit (PSU) as this could also cause problems when running for a long period without being turned off.

Why Is My Extruder Clicking?

Some 3D printers will click when extruding filament to the nozzle because of a few different causes.

The most common reason is that your printer’s stepper motor has stalled at either end of its rotation, and so it “clicks” each time one of these motors reaches its limit points.

This usually occurs if you’ve over-extruded or are using poor-quality filament. Still, it can also happen due to mechanical failure on the machine itself (such as loose wiring).

However, even with great attention paid to preventing this issue from occurring, some 3D printers have an inherent design flaw, making them more likely to stall in place during extrusion than others.

There isn’t a surefire way to tell which 3D printer you have until it happens (unless someone’s already done the research on your model and told you), but the best way to prevent extruder motor clicking is to make sure that your filament isn’t too low, over-extruding or using poor quality filament.

-

Section One: Preventing 3D Printer Extruder Motor Clicking(& PTFE Tube Test)

A common cause of extruder motors clicking once per revolution is when they stall at either end of their rotation due to mechanical failure in wiring, a loose wire connecting them, or other issues with the machine itself.

For instance, if there are two wires instead of one – usually nylon-covered electrician’s tape kind will suffice – then these wires should be connected to do the least amount of bending to prevent this.

Before breaking down your whole hot end and redoing the nozzle, always check your PTFE clearance first!

To test, remove the end of the tube from the hot end (leave another end in the extruder) and squeeze your extruder arm to manually push filament or filament path past the extruder and through the PTFE tube; if it moves smoothly, your problem is elsewhere.

Make sure the active center of gears and bearing are at the height of the filament path.

-

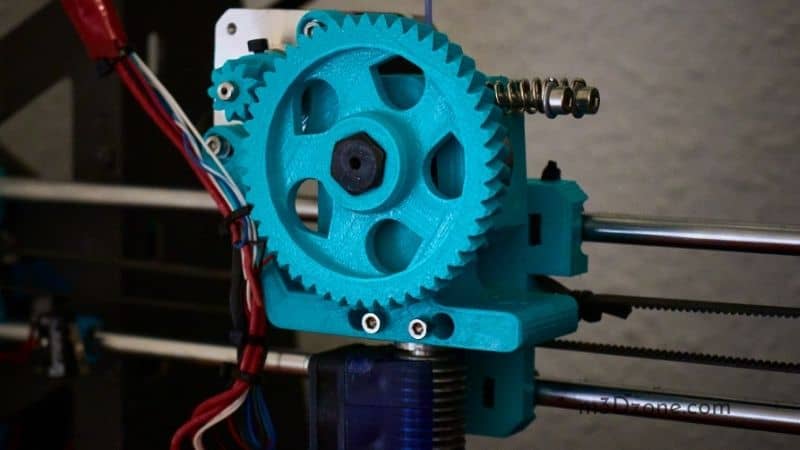

Section Two: 3D Printer Extruder Motor Clicking – Fixing Extruder Gears

If your extruder motor is clicking once per revolution, and it doesn’t stop after you power cycle or unplug, then there’s something wrong with it.

Common fixes are as follows:

- Check that the wires powering the stepper motors are connected securely at both ends (to avoid them coming loose from vibration)

- Ensure that a wire hasn’t come to lose inside any part of your 3d printer, which can cause electrical shorts or provide an open circuit for electricity to flow through. If you have a Bowden tube, just looking at the moving tube, you can tell.

To fix this, try switching out your extruder’s stepper motors with a higher voltage model; many 3d printer kits come with these installed, and it could be as simple as replacing them to prevent extruder clicking once again.

If the gear is too low, it may crush the filament against the idler bearing.

To fix this, make sure that the filament can be freely pulled through the feeder. If it can’t, then you must realign the gear until the filament can fit. Less commonly, the idler bearing could become worn out over time.

Another reason for an extrusion motor click is when the filament gets stuck inside of its feeding tube or at some point on its way from the spool to being fed into your 3D Printer Extruder nozzle.

If you can’t find where exactly it might have become jammed, then pull off one end of your old filament and feed new filament through before turning on the machine – if this fixes your issue, then there should be no problem with the 3D Printer Extruder motor.

Alternatively, suppose you’ve previously used a high-temperature printing material and now use a lower temperature material. In that case, there could be an unflushed residue of the higher temperature material that’s remained in the nozzle.

With this issue, try and make sure that your filament is being fed into your extruder nozzle consistently. If it’s not, then you may need to calibrate the spool holder on either side of or above your 3D printer to get better feed from one end for more reliable printing results.

Suppose none of these solutions works even after adjusting settings. In that case, there could be an issue with stepper motor driver board connections which will require some disassembly and troubleshooting before we know what might have gone wrong.

The Importance of Regular Maintenance for Your 3d Printers

– 3D printers are mechanical devices. They will at some point need to be maintained for their longevity and optimal performance.

– Regular maintenance includes checking all screws, nuts, bolts, or other fasteners that hold the parts of your 3D printer together.

– Check belts to see if they’re loose or broken and replace them with a new belt when necessary.

– Keep your extruder nozzle system clean by using a brush on every print job.

– Keep your 3D printer clean by dusting it with a soft cloth or rag.

– Clean the inside of the 3d printer with hot water and dish soap.

– Check for any visible damage on pieces, motors, wires, etc.

Note: If you’re having extruder issues like what happens in our video example at the top (extrusion not consistent), then we recommend cleaning out all filament material from the nozzle before doing this maintenance to get maximum performance back again!

Other Things to Consider When Troubleshooting This Issue

– Check the wiring for any obvious damage

– Inspect your 3d printer to look for any other potential issues such as a loose connector, stepper motors that are not turning properly, or wires that have come undone.

– Make sure you’re using quality filament and extruding at the correct temperature (220 degrees Celsius) – It is always best to perform these maintenance tasks when possible during the printing process. Hence, there’s no pause in production while troubleshooting this issue.

If unable to resolve the problem after performing all of these steps, contact us for all your extrusion issues, including the print head, extruder assembly, and extruder gear.

Tips for Preventing the Problem From Happening Again in the Future

– Follow the 3D printer’s manual and use wiring diagrams with the 3D printing software kit.

– Use a brush to clean off dirt or debris on homing switches after every print job, as this will prevent clogging of extruder nozzles. This is an essential step for the long-term maintenance of your 3D printer nozzle system.

When cleaning the homing switches, wipe them down with an alcohol wipe or dry cloth. This will remove any dirt and flux from extruding, which would lessen its longevity.

After cleaning out these homing switches, they should resume their normal function to stop rotation when instructed to do so as they had been before clicking started occurring.

Lowering the printing speed is a sensible option if your printing temperature is already set at the high end of the range for the same filament. If this is the root cause of the clicking sound, a reduced printing speed should immediately resolve the problem.

If you don’t have a glass print bed yet, consider getting one. A glass print bed does not warp when heated, unlike one made of metal.

This should alleviate a major source of bed leveling issues. Clogged nozzle one of the most common culprits of a clicking sound in the extruder is a clogged nozzle.

Why Should You Be Concerned if Your 3D Printer Extruder Clicks

Suppose your extruder has been working fine for some time now but suddenly started having this issue.

In that case, it’s likely due to a change in environmental conditions such as an increase or decrease in temperature, which could cause thermal expansion or contraction, causing faulty connections with components near where they reside inside of the printer extruder clicking mechanism.

It might also be caused by moisture build-up from humidity or rain impacting any circuit board wiring close by.

Final Thoughts

Why is your 3D printer extruder clicking? Well, you might need to make sure that the filament is feeding into it at a consistent rate or turn up the tension on its spool holder.

If none of those solutions works even after making adjustments, there could be an issue with stepper motor connections, requiring some disassembly and troubleshooting. Get in touch with a professional repairman!

Recommended Reading

3D Print Stringing. 5 Easy Ways to Fix It & Prevent It!

So, what is 3d print stringing? Stringing occurs when filaments leak through your 3D printer nozzle in places where they shouldn't. Fixing stringing is easy.

PETG Not Sticking to Bed? Find Out Why!

Why Is PETG Not Sticking to Bed? There could be reasons like: the bed is too cold, or maybe there might be something stuck inside extruder etc. Let's find out!

How to Clean a 3D Printer Nozzle?

How to clean a 3D printer nozzle? Different ways: brushing the nozzle, then heat it and use a wire to remove the dirt. Or, you can soak the nozzle in acetone.