What 3D printing speed settings will you use to print a 3D model that stands out? What if you mess up your project by using faster or slower speed settings?

These are some of the questions people have when deciding on a printing speed. 3D printing technology uses additive manufacturing processes, making it essential to mind the amount of material you deposit on the printer bed.

3D printing speeds determine how much filament your printer’s extruder will deposit on the 3D printer bed. To achieve an exquisite 3D model, you must set the printing speed according to the category of 3D printers you use.

For slow 3D printers, use 40mm per second to 80mm per second 3D printing speeds. Mid-speed printers work best with 100 mm per second printing speeds, while those who want to print faster use 150mm per second and above in fast-speed 3D printers.

Quick Navigation

Since printing speeds control the flow rate, let us understand these 3D printing speeds better with this article.

What Is the Best Print Speed for 3D Desktop Printers?

Before we dive into the best print speed to use in desktop printers, it would help you first understand that print speed is a part of speed settings. For this reason, you have to consider how you set the speed of the 3D printer.

Your printer’s print speed regulates how fast your extruder motors move to extrude either more or less material. If you want to reduce your printing time, adjusting the printing speed will help you. As much as faster printing speeds minimize print time, they affect the quality of your 3D prints.

To avoid damaging extra-ordinary models in the making, 3D printer manufacturers have developed speed regulations. These regulations are not limited to desktop printers; even large 3D printers follow speed settings regulations.

How Fast Can 3D Printers Print?

Both fast and slow print speed settings have pros and cons. For instance, if you are creating a 3D-printed object at a slow print speed, you risk deforming it. This is because the nozzle and plastic are too close to each other for prolonged durations.

High 3D printing speed settings, on the other hand, expose your 3D printers to overheating problems. The cooling system will not cool the extruder fast enough; under extrusion will occur, creating weaker layer adhesion.

The bottom line in achieving desirable 3D printed object quality is mastering print speed settings. Here is how you go about deciding the best 3D printer settings for your printing process.

3D Printer Settings

- First, consider the model’s outer wall. How fast do you want the exterior of your model to be printed? If your priority is on surface quality, it will help if you reduce the print speed. In simple terms, use lower print speed settings for more satisfactory surface quality.

- The second factor to consider is the interior walls’ printing speed. Here, make sure you use the same print speed as the one you use in making the overall model. The 3D printer speed here needs to reduce your printing time without lowering the 3D print strength.

- Next, consider the infill printing speed. It needs to also reduce printing time without compromising your model’s stability.

- The last speed setting to consider is how fast you want your 3D printed objects’ bottom and top layers to be printed. If you want a better surface quality, use a slightly lower 3D print speed.

Be sure to also work on achieving optimal retraction settings if you want high-quality 3D prints. Retraction speed settings are responsible for determining the travel speed at which your 3D printer will pull the filament back before any travel moves.

When you set retraction speed too low, your 3D print will have blobs that are not appealing to the eye. Using too high refraction speeds, on the other hand, results in grinding filaments and eventually unpleasant lumps on the 3D model.

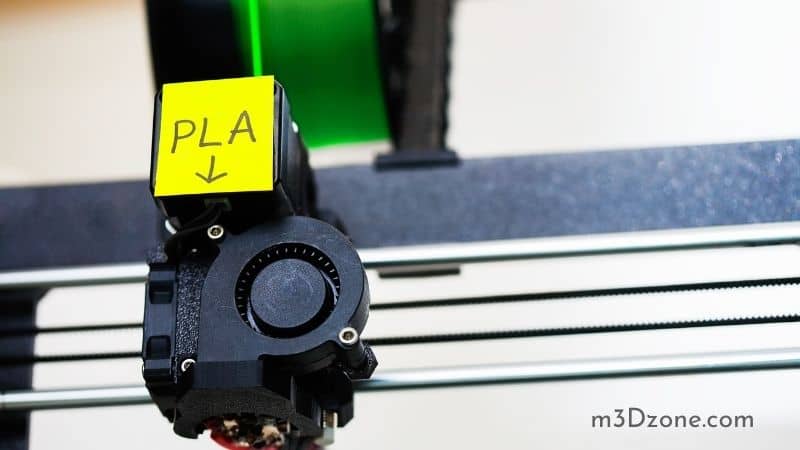

What is a Good Print Speed For PLA?

Whenever you make 3D prints using plastic filaments like PLA or PLA+, it is best to use print speeds of between 30mm and 90mm per second. Manufacturers who want better results use printing speeds that are on the lower end.

It is important to note that there are factors that influence the print speed you use. The amount of plastic you extrude also has a notable impact on the print speed. Similarly, 3D printing layer thickness also affects printing speed.

How much plastic filament you will extrude to make a part’s outline is shown through shell settings.

Increasing shell settings in additive manufacturing means more filament will be extruded. As a result, the line width of your 3D print will increase. The printing process will end up consuming more printing time.

If you have a more significant infill percentage to print, your printing speed will be affected. This is because the infill has a predetermined pattern. Printing that shape is what affects the printing speed.

Other than the pattern, infill density also comes to play, affecting your printing time. If the object you are printing has a higher infill density, be ready to spend more time printing. The part or parts you create will be stronger than those created using other manufacturing processes on the upside.

Layer height is another crucial determinant of printing speed. When you are printing an object with a more significant layer height, you will extrude more filament at a time. The result will be increased layer thickness and faster printing speeds.

If the nozzle size is large, more filament will be extruded when printing each layer. You will therefore need to have a high printing speed setting to avoid over extruding.

How to Set the Printing Speed

If you want to set the printing speed, you will need to launch the slicer software on your PC (for example Cura). Locate the basic tab on your slicer software and click on print speed.

For people using older versions, locating the print speed settings demand that you switch to advanced mode. You will then open your slicer software’s speed tab, where you will access print speed settings.

When you alter any setting on the slicing software, including the 3D printing speed setting, the software will recalculate the time required to complete the printing process.

You don’t have to be worried about waiting longer than estimated since the software calculates a print duration that is identical to real-world time.

Does Print Speed Affect Quality?

Without beating around the bush, yes. Print speed affects the quality of your 3D prints. If you use a lower speed to create a 3D model, you will achieve better quality than when you use a higher speed. This, however, occurs when your printer is not operating in optimal conditions.

Nonetheless, there is an argument that printing speed does not necessarily have to impact the print’s quality. This is because there are a few other factors that directly impact 3D printing speed without compromising the print’s quality.

-

The Type of 3D Printing Material

If you are using high-quality support material, you will print faster since you don’t have to keep unclogging the nozzle when the support material gets stuck. Once you are done printing the model, you will remove the material without reducing the print quality.

Printing polymer also comes in different types. When used at the same speed, each of these polymer types will give 3D models of other qualities. Print speed settings do not create the difference; the difference in filament texture creates it.

You might like: Types of 3D Printers

-

3D Printer Type

Your 3D printer types affect the quality of the 3D prints you will get without necessarily being influenced by speed. Look at this case from this perspective; you have a high-quality 3D printer. You set it to a high-speed setting and get first-class quality 3D prints.

When you use a 3D printer of lower quality at the same print speed, the quality of the model you get will be lower. Consequently, the price of one of the first-class models will be more than the second model’s price.

What’s Our Take?

Layer heights and line width affect the speed you print 3D objects at, increasing the quality and time consumed to manufacture any 3D parts.

When deciding the best 3D printing speed to use, it will help if you account for all aspects, including printer type, 3D printer’s nozzle size, line width, and other factors discussed in this article.

Recommended Reading

Lubricate 3D Printer. Things You Need to Know!

Lubricate 3D printer guide. When applying lubricant to the various parts of your 3D printer, you need to know which lubricant works best and how to apply it.

Can You 3D Print Clear Plastic?

Yes! You can 3D print clear plastic! Traditional materials used in prototyping, such as clay, foam, and fabric, are accessible to 3D print.

Can You Sandblast 3D Prints?

Do you have problems with your 3D printer not printing smoothly? You can try to sandblast your 3d prints. But, can you sandblast 3D prints really? Let's see!