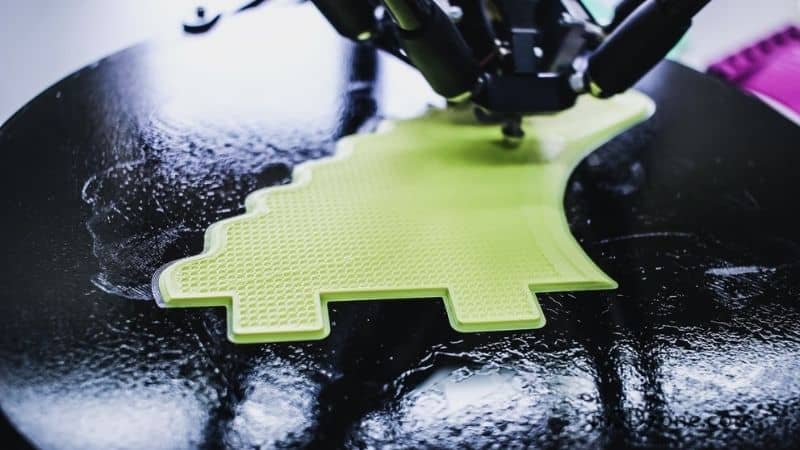

3D printers have made a difference in the designing of objects even the tiniest ones.

As an Amazon Associate, I earn from qualifying purchases. If you make a purchase after clicking on a link I may earn a small commission at no extra cost to you.

However, a lot of attention and care has to be considered to produce fine details. Do you know that you can create objects on your own and a 3D printer makes the work so easy with efficiency?

Quick Navigation

- So, How Small Can a 3D Printer Print Really?

- What Are the Common Types of 3D Printers?

- Can FDM 3D Printers Print Really Small Objects?

- Can SLA 3D Printers Print Really Small Objects?

- Can a DLP 3D Printer Print Really Small Objects?

- What Are the Important Factors to Consider When Printing Small Objects?

- Final Thoughts

However, you will require patience and practice to perfect your skill, especially when working on tiny objects. Working with a 3D printer guarantees better results than the traditional approach.

So, How Small Can a 3D Printer Print Really?

How small can a 3D printer print depends on the printer’s additive manufacturing.

What Are the Common Types of 3D Printers?

There exist 3 common types of 3D printers namely the FDM (fused deposition modeling) 3D printers, SLA (stereolithography) 3D printers, and DLP (digital light processing) 3D printers.

All these types of 3D printers utilize different mechanical properties to facilitate object 3d printing and quality.

a) Stereolithography (SLA printers)

SLA 3D printer works to produce models and prototypes for molten plastic materials. SLA produces outputs with very high accuracy, water, and airtight plastic models.

SLA 3D printer facilitates a smooth finish for the surfaces and is also very detailed in the outcomes for a design. If you are looking for the finest design for a plastic model then the SLA 3D printer is ideal.

Usually, the SLA 3D printers work to compress layers of liquid resin into a clear, finished, and solid design. This process of achieving the solid object from the SLA 3d printer is known as photopolymerization.

SLA 3D printers are ideal for working in the engineering and manufacturing of thermoplastic materials. SLA is recommended for efficient 3d printing of materials at room temperature.

They employ the use of light and not heat which eliminates the problem of thermal stretching and contraction design distortion. Designs made from SLA printing are highly isotropic and therefore do no change according to orientation.

b) Digital light processing (DLP printers)

Just like SLA printers, DLP uses resin in facilitating three-dimensions printing for the smallest feature. The process designs object in layers using an upside-down technology.

The liquid resin is hardened once the shapes are thrown and display in front of the digital processor screen.

The digital screen made of microscopic detailed mirrors usually reflects light and is positioned on the semiconductor.

DLP three-dimension printing produces the most accurate plastic designs with a higher resolution.

Their printing outcomes have a smoother and desirable surface finish compared to the SLA 3d printers and are highly detailed.

c) Fused disposition model (FDM printer)

During the FDM three-dimensional printing, acrylonitrile butadiene styrene and polylactic acid are produced upon heating the printer nozzle melting the plastic to create designs. FDM 3d printers are mostly used by consumers as they are less complicated.

You only need to press a button after powering the printer on and positioning the CAD file.

Working with FDM 3d printers is time-saving as they produce designs faster. The downside of working with FDM 3d printing is that they produce substandard objects as they cannot process a single object but multiples.

The models produced are also not long-lasting as they are prone to thermal stresses in case of heat exposure.

FDM objects are also easily broken when exposed to cold and therefore unreliable. FDM printing cannot produce models with a smooth finish because of their technological composition.

Usually, the design will have sharp edges because of the layering during production with limited control. An FDM output has a weak tolerance ability leading to design inconsistencies.

Can FDM 3D Printers Print Really Small Objects?

How small FDM printers prints depend on their printing nozzle diameter. They can print a design as small as 0.4 millimeters dimension for their smaller features.

It is also possible to print an even smaller design of 0.15 millimeters using a nozzle upgrade from third parties. You will require to be very careful while working with the FDM 3d printer to get a perfect model.

Creating a perfect FDM design depends on your accuracy in movement and the intended shape. A major setback when using FDM to print small objects is that you can control the flow of the thermoplastic material and stop it.

FDM printer is, therefore, a reliable option for creating models of different sizes and not the same size.

Can SLA 3D Printers Print Really Small Objects?

The laser beam spot size on the SLA printer determines the smallest resolution for an object. It is quite convenient to use the SLA to print tiny features, tall and slim as you will not experience any thermal uncertainties.

Working with SLA is guided by the x,y, and z dimensional resolutions. Usually, the XY resolution is controlled by the size of the laser spot. Z resolution defines the thickness and length of the final model.

Can a DLP 3D Printer Print Really Small Objects?

DLP creates prototypes of defined resolution and details. It is possible to work with different heights of between 25 to 300 microns while using DLP. Creating small models is measured by pixel size for XY resolution for the DLP 3d printers.

You will need to determine a balance between the build volume and resolution to effectively work with the DLP 3d printers. This is because the digital projector controls the pixels and volume to use for a given time.

Working with the projector very close to the optical windows will produce very small pixels with greater resolution. However, this will reduce the space available for building the objects and will require your expertise to pool through successfully.

Working with the DLP printers doesn’t utilize a single light source like when working with the SLA. You will require to apply different light supplies for the lenses and the build-in platform.

It is logical that you expect a difference in the size of the pixels found on the object surface and those in the center.

The working mechanism devised in the DLP 3d printers allows for this to facilitate finer and detailed end products without surface roughness.

Working with 3d printers requires experience and skills to produce the desired end products. The diversity in 3d printers is heavily influenced by the creation of models of different calibers and qualities.

You will realize that despite the differences among the 3d printers each of them have an added advantage over the other. As a user, you will require to understand all these dynamics before adopting the right 3d printer for your use.

Also, recognize that working with the acceptable minimal threshold for the 3d printers will save you lots of disappointments.

What Are the Important Factors to Consider When Printing Small Objects?

Let’s dive into some important factors that you need to keep in mind before 3D printing small objects.

1. Ensure That Your Models Are Realistic

As much as it is true that working with 3d printers can create almost anything you can think of, it’s only prudent that you utilize your skills in what is realistic. Do not imaging creating a small object model that can defile the laws of gravity as it is unrealistic

2. Ensure to Observe the Recommended Usage Guidelines

Different 3d printers have been designed to create specific end products for the users. It’s therefore important that you understand and keep the guidelines as directed while creating prototypes.

The first thing to do before engaging in any 3d printing work is to read and interpreting the defined user instructions. This way you will avoid save time and avoid wastage in case you adopted a wrongful approach. The dimensions proposed for use should be strictly adhered to for the best outcomes for your model.

3. Use Support

Creating small objects with 3D printers can be quite challenging and it’s therefore advisable to build up their support as you carry along with the processing.

Using support ensures that your objects do not crumble and you can always remove them when the procedure is complete. Keep in mind the thickness aspect of it also, which determines the model’s ability to stand on its own once the support has been removed.

4. Thickness

You must observe the recommended thickness depending on the type of 3d printer you could be using. Layer thickness (layer height) plays a vital role in the look of your model at the end.

5. Producing Several Printed Parts

Some 3d printers allow creating small features model and therefore quite efficient and time-saving. However, you must allow a few seconds of print time for the different parts to cool down during production before the next one is processed.

This is because working with small objects leaves lots of free space on the platform which you can utilize by working in turns. You can further enhance the process by reducing the print speed in between productions.

6. Use DLP Printers

Use DLP printers to create small towers with efficiency and to achieve print accuracy.

Final Thoughts

It’s clear that indeed the SLA and DLP printers work well to create smaller models and prototypes compared to the FDM printers. You only need to know what it is that you want to create using a 3d printer to adopt the right model for your work.

SLP and DLP work well in manufacturing and engineering solutions and produce high-resolution models with precision and accuracy.

Working well with the DLP and SLA 3d printers requires expertise and experience to produce quality prototypes. FDM 3d printers are easy to use and are mostly used by consumers.

Recommended Reading

How to Cut ABS Plastic [3D Printing Useful Guide]

Do you already know how to cut ABS plastic? If not let me show you some easy ways. To cut ABS plastic sheets, you will undoubtedly require power tools.

Casting vs 3D Printing. What to Choose?

Casting vs 3D printing. 3D metal printing gives you full control over the casting process, which is not the case with traditional metal casting.

Should You Invest In a 3D Printer?

Should you invest in a 3D printer? Yes! You should invest in a 3D printer because it's a good investment. Using your creativity you can print all...