Every 3D printing enthusiast dreams of a seamless 3D printing process that delivers the best value.

None enjoys frequent challenges from 3D printer mechanical problems, software malfunction, and filament issues.

Quick Navigation

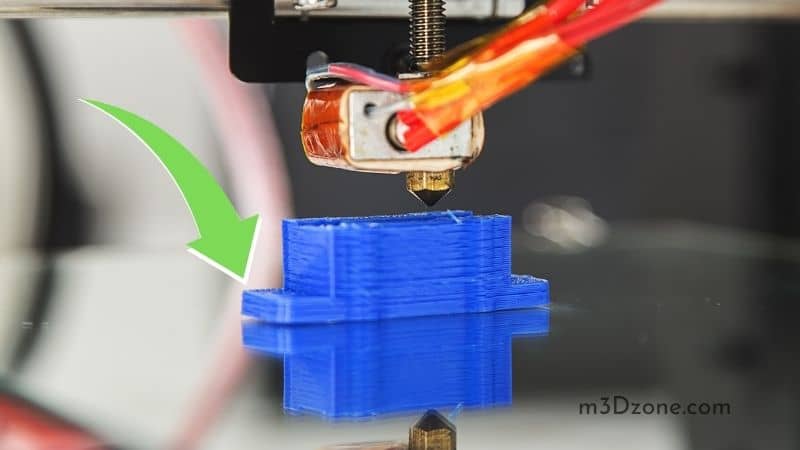

For example, 3D print warping is a common problem that impacts print quality, and 3D printing enthusiasts need to eliminate it.

Material shrinkage causes 3D print warping during the printing process. As a result, the print corners lift and detach from the build platform.

PETG Corners Lifting Issue

PETG plastic filament expands slightly under heat but contracts on cooling down. If the material contracts too much, it results in print corners bending up from the print surface.

The article provides sufficient and well-researched information on the PETG filament. More so, PETG corner lifting issue and the best way of fixing it.

What Is PETG Filament?

PETG is short for Polyethylene Terephthalate Glycol.

It is made of co-polyester, which makes it durable and flexible. In 3D printing circles, PETG is seen as an enhancement of PET filament. The “G” added to PET makes it PET-G.

“G” stands for Glycol- modified, a property that makes the product shiny and gives it a glass-like look.

PETG filament is an alternative to the more popular PLA filament as it also boasts ABS filament properties and is relatively easy to use.

Additionally, its low forming temperature makes it easily Vaccum and heat bend.

Features of PETG Filament

PETG filament stands out for these qualities:

- Flexibility

- Strength

- Temperature and impact resistance

Advantages of PETG Filament

- Strong filament

- Cost-effective

- Easy to form

- Food safe

- Easy to color

- Recyclable

- Odorless emission

- Nontoxic

Disadvantages of PETG Filament

- Few brands available

- Warping issues

- Sticky

- High printing temperature

- High bed temperature

- Not suitable for brass nozzles

- Less resistant to scratches

Applications of PETG Filaments

PETG filament stands out as one of the most used filaments in industrial and medical applications. Also, it’s prominently used in signage and packaging.

- Manufacturing medical braces

- Electronic devices

- Used for covers

- Manufacturing bottles

- Graphic displays

What Is 3D Filament Lifting?

The result of distortion is 3D print corner lifting. It happens during the print curing or cooling process.

So what causes print curling or warping?

If a 3D print has large faces next to the print bed or more extensive footprint layers above the first layer, it increases warping force. It results in the production of deformed, low-quality 3D prints.

Furthermore, filaments with a higher infill level have more force and more material concentration. Thus, it may easily cause warping.

What Causes Lifting in 3D Printing?

First Layer

The first layer is critical to any FDM 3D print. It primarily forms the basic foundation on which subsequent or upper layers are laid.

It would be helpful to have a perfect printer bed adhesion.

Otherwise, poorly adhered first few layers cause the 3D print to dislodge from the build plate resulting in PETG warping.

Heated Bed/Print Bed Temperature

If your 3D printer heated bed becomes extremely hot, be cautious, as it is a red flag that print warping may occur.

A scorching print bed causes heavy upper layers to compress the lower layers. When compressed, the lower layers tend to sag and flow outwards, resulting in warping.

Adjust your print bed temperatures to optimal values to get the best print quality devoid of print lifting.

Notably, the glass bed transition temperature of PETG stands at 70-80 degrees Celsius. Thus, avoid heating your heated bed beyond this temperature range.

Nozzle Temperature

The nozzle temperature has a vital role in ensuring that you reduce warping. Remember, better adhesion is the number one solution to warping issues.

Why do you think users tend to forget calibrating the nozzle print temperature?

3D printer users forget to calibrate the nozzle print temperatures because printing with overheated filaments is more comfortable. It increases layer adhesion hence helping stop warping.

Significantly, extruder temperature impression works in a similar way to cooling fans. The cooling settings render the nozzle to lower the molten PETG filament temperatures.

More importantly, a low extruder temperature reduces print bed adhesion. Conversely, the high nozzle temperatures make plastic liquid and, in the process, improve bed adhesion.

Wet PETG Filament

Most 3D printing filaments are hygroscopic, meaning they absorb moisture because of the ambient temperature. Filaments drink water at different levels, and PETG remains in the middle of the pack.

PETG filament does not absorb too much water. However, moisture in a filament negatively impacts print quality.

More significantly, wet PETG filaments area cause numerous printing problems with warping topping the list.

High Printing Speed

A high print speed is a primary cause of 3D print warping. Significantly, slower prints give the printer time to release excess heat. It results in the print object cooling down even if it eliminates distortion.

Contrastingly, printing fast does not allow the printer to release heat. As such, the print object cools down evenly, causing warping.

Ignoring Enclosure Use

If you want to keep your printing area warm, use an enclosure. It can be in the form of a simple cardboard box, provided it can help you keep the temperature surrounding your heated bed homogeneous.

Thus, it helps print objects cool evenly, eliminating chances of PETG print warping. So if you don’t use an enclosure in certain 3D printers, you will encounter corner lifting print issues.

How Do I Stop My PETG From Lifting?

Use a Printer Enclosure When 3D Printing

If you’re keen on achieving Zero warping during the 3D printing process, use a 3D printer enclosure. A heated chamber helps the 3D printer avoid temperature changes around the print bed.

If you keep the build surface temperature intact, you allow the 3D print to cool evenly. Importantly, it stops warping.

It will be helpful to use an enclosure while printing as it helps in safety, dust, noise, and toxic fumes protection.

Adjust Your Heated Bed Temperature

If you increase your bed temperature, you’ll stop your PETG from warping. How does it happen? Increasing print bed temperature controls the rapid change of temperature. In the process, it helps heat emit evenly on the model.

Remember to follow the PETG plastic manufacturer’s requirements for heated bed temperatures between 70-80 degrees Celsius.

Use Adhesives on the Build Plate

3D print object movements cause material shrinkage that leads to warping. Therefore, to avoid distortion, apply a suitable adhesive on the print bed to help stick the print object on it.

Also, there are numerous suitable adhesives in the market that you can use on the print bed surface.

- Glue stick

- Blue painter’s tape

- PEI bed surface

Turn Off Cooling for the First Few Layers

If you don’t want to experience warping issues during the printing process, be sure to turn off the cooling system for the first few layers.

Lower your cooling settings to ensure you slow down the cooling process. Also, you can change your printer layer height to help your printer fan engage regular speed directly in Cura settings.

Significantly, delay starting your fans if you notice print curling early on in the process.

Level Your Build Platform

Pressure caused by rapid cooling and material shrinking results in warping of the print edges. The best way of eliminating warping is to use a flat and leveled print bed whenever 3D printing.

A nicely leveled build platform improves material adhesion on the build plate. Add adhesives like a glue stick to the flat print bed, and you are good to 3D print without worrying about print curling.

What Are the Problems Caused by Lifting in 3D Printing?

3D print lifting causes a severe quality problem due to instant or rapid temperature changes in the build platform.

It changes the dimension of the print object so that the thing may not serve the intended purpose.

Furthermore, it negatively impacts the overall print quality as you deliver low-quality print.

PETG Corners Lifting Solution in 9 Easy Steps

- Level your print bed by adjusting the z-offset

- Spread a layer of PVA glue on the build plate to help print the object to stick

- Use strips of painter’s tape for ease of cleaning

- Increase surface area by adding a brim. It also improves print grip on the build plate

- Deploy mouse ears to your print corners stick

- Prevent room temperature fluctuations by closing your doors and windows

- If you notice print curling, turn off cooling fans for the first few layers

- Lower the print speed and nozzle temperature

- Use a heated print bed to even out the temperature

Conclusion

Warping or 3D corner print lifting occurs due to instant and rapid temperature changes around the 3D print bed. Also, material shrinkage causes warping.

To avoid a printed part warping, it will be best if you work on avoiding abrupt temperature changes in areas around the print bed and avoid material shrinkage.

Recommended Reading

Ender 3 Auto Bed Leveling. Should You Upgrade?

Ender 3 auto bed leveling is a feature that allows the printer to automatically level the bed, to ensure that it is always level with the print head.

How to Make a 3D Model From a Picture in 5 Easy Steps

How to make a 3D model from a picture in 5 easy steps! With a few practice runs, you will be able to quickly turn any 2D pictures into 3D objects. Let's see!

Can 3D Printing Replace Casting?

Can 3D printing replace casting? In the casting process, molten metal or plastic is poured into a mold with a cavity or hollow with the desired shape.