The worst experience you could ever go through is the nagging bug of PLA failing to stick to the PEI sheet.

But you don’t know that the bug is an error you can easily fix and have the best results of your printed object.

Quick Navigation

- PLA Not Sticking to PEI? How Do You Get PEI to Stick?

- 12 Easy Fixes if Your PLA Isn’t Sticking to PEI Sheet

- 1. Consider Levelling Your Print Bed

- What Happens When the Print Bed Is Not Leveled?

- 2. Ensure You Optimize Your First Layer Printing Speed

- 3. Optimize Your First Layer Flow Rate

- 4. Adjust Your Print Bed Temperature

- 5. Adjust Your Printing Temperature

- 6. Adjust the Z-Offset value

- 7. Make Use of a Raft or Brim

- 8. Ensure Your Bed Is Not Warped

- 9. Unclog or Install a New Nozzle

- 10. Ensure Your Print Bed Is Clean

- 11. Consider Using Print Bed Adhesives

- 12. Use Sandpaper to Make PEI Sheet Rougher

- Does Acetone Melt PEI Sheet?

- Conclusion

This article will take you through a comprehensive troubleshooting technique you can apply to fix the bug when printing PLA.

The primary solution to PLA not sticking to the PEI sheet is leveling the print bed and adjusting the printing temperature to the optimum.

Setting the right print temperature makes the filament softer and makes it adhere to the print bed better.

It is also crucial that you have a robust model foundation using a raft and ensure you do not have a damaged or clogged nozzle.

PLA Not Sticking to PEI? How Do You Get PEI to Stick?

The answer will come clear only if you understand why PLA has problems sticking to the print bed.

The starting point is to have an effective first layer in your 3D prints. That is because, at that stage, any error can immensely disrupt the outcome of your model prints.

So, ensure that the bed adhesion of your 3D printer is ideally in order and you will solve the problem of PLA not sticking.

The initial layer will not be in place if for any of the following reasons:

- The print bed is not level

- The print bed temperature is abnormally low

- Your 3D printing temperature is too low

- The Z-Offset value is wrongly set.

- You have a warped print bed.

- Your print nozzle is damaged or clogged

- There is poor or no use of print bed adhesives

- Your print speed of the initial layer is set too high

- The flow rate of the initial layer is set too low

- Your filament is wet above normal

12 Easy Fixes if Your PLA Isn’t Sticking to PEI Sheet

Your 3D printing will become more exciting if you familiarize yourself with the following approaches. These approaches are crucial since you will often need to use them for high-quality PLA prints.

1. Consider Levelling Your Print Bed

The first stop when your PLA has print bed sticking problems is to check the bed level. A perfectly level print bed will create a reasonable distance between the nozzle and the bed surface for the extrusion of the filament.

An optimal distance allows the nozzle to exert pressure on the build plate. Usually, 0.1mm is approximately the optimal distance. That is about the thickness of an A4 paper.

What Happens When the Print Bed Is Not Leveled?

An unleveled print bed will cause your extruded filament to unevenly adhere to the PEI sheets. That will lead to poor bed adhesion since the filament will not adhere to some print bed surfaces.

How to Level Your Print Bed Manually

- Lower or raise the print bed using leveling knobs.

- Auto-home the printer to have the nozzle set at its default.

- Ensure the bed is flat and not too far from the nozzle when you auto-home your printer.

- Have your bed heat at the default print temperature of around fifty degrees Celsius.

- Adjust starting from the left corner until the nozzle is at the desired distance from the print bed.

- Place a piece of paper under the nozzle and lower the bed until there is enough space for the paper to wiggle.

- First layer calibration is the most crucial. You may need to carry out multiple first-layer calibrations to achieve a perfect level of your print bed.

- After setting the distance equally from all corners, you can test your printer.

Automatic Bed Levelling

- Use your 3D printer bed leveling sensor set at the default working scenario.

- Access the service using the printer’s menu.

- Navigate to the bed leveling attribute on the control screen

- Press the bed leveling button, and the printer will automatically adjust based on default leveling measurements.

2. Ensure You Optimize Your First Layer Printing Speed

You should not set your initial layer print speed too high. A lower print speed recommended at 20mm/s is the best suited to help the first layers stick correctly to the print bed.

The initial layer speed is independent of other settings in your 3D printer. It remains the same throughout the print process, so getting it right initially will fix most bed adhesion problems.

3. Optimize Your First Layer Flow Rate

Your first layers’ flow rate is critical since you use it to determine how much filament to extrude. Increased flow rate facilitates the extrusion of more material. You should set it at 100% to push the PLA at a greater force.

The increased flow rate will push more filaments into the build plate. More material is what you need to improve adhesion.

Note that you use an increased flow rate when the print bed is not leveled. You should reduce the flow rate accordingly if the print bed is too close and increase it if it is too far.

The flow rate setting is effective only when you haven’t properly leveled your print bed.

4. Adjust Your Print Bed Temperature

Increasing your bed temperature will make your PLA adhere better to the bed. PLA requires a recommended bed temp of between forty and sixty degrees Celsius.

Low bed temperature will cause the same problem as low printing temperature.

5. Adjust Your Printing Temperature

Your filament will stick better to the print bed if it is softer. You soften it by increasing the printing temperature. The initial layer temperature is also crucial since it will affect the entire printing process.

Consequently, low printing temperature will reduce good adhesion. Calibrate the temperature, increase it by five to ten degrees Celsius, and calibrate it until bed adhesion improves.

Make sure your cooling fan is working correctly.

6. Adjust the Z-Offset value

Your 3D printer adjusts the nozzle height, a process known as Z-offset. Z-offset is mainly helpful when seeking an accurate bed leveling. A properly leveled print bed usually has the print nozzle in a perfect location.

If you want to raise the nozzle, increase the Z-offset value, and if you’re going to lower it, decrease it to a negative value.

7. Make Use of a Raft or Brim

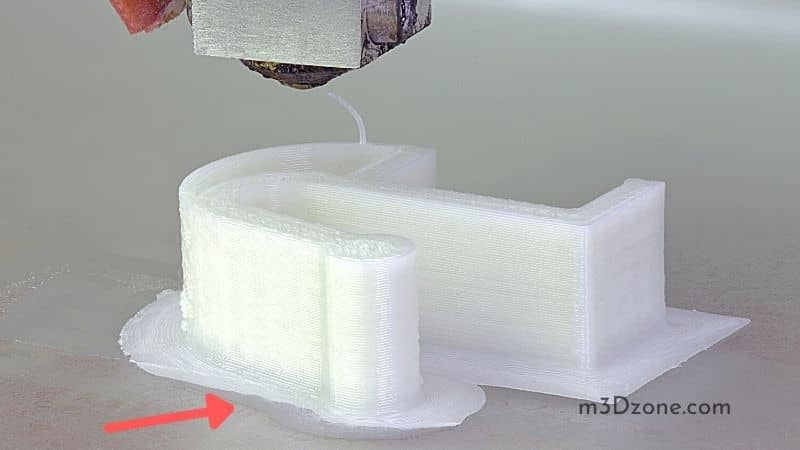

Using raft or brim helps increase PLA bed adhesion to the build plate. The raft /brim helps in building stronger contact support.

It is extra print support that is added under the model to stabilize the PLA bed adhesion.

8. Ensure Your Bed Is Not Warped

If your 3D print bed is warped, it will cause your PLA to have difficulty sticking to the heated bed. You may want to use a ruler to test the flatness of your build plate.

The build plate may sometimes bend after heating, causing uneven filament distribution. If you find out that the build surface is warped, the best solution is to replace it.

9. Unclog or Install a New Nozzle

A damaged or clogged nozzle is a common issue that causes problems with PLA adhesion. If the nozzle is damaged, it will prevent the smooth flow of filament that will affect its sticking to the PEI bed.

If your nozzle is clogged, you may use a cleaning filament or use the cold pull method to clean it.

10. Ensure Your Print Bed Is Clean

A dirty print bed will cause PLA 3D adhesion failures and lower the quality of your prints. The source of dirt could be when you frequently touch the print bed with oily hands.

Always make sure your bed is clean before starting the next print by following the procedure below:

- Use a clean, soft cloth or paper towel saturated with at least 70% acetone or isopropyl alcohol.

- Pour soapy water on the soft cloth and gently wipe the print surface area. It is recommended that you use hot water and dish soap to remove any grease effectively.

- Allow the bed to dry freely until all the liquid has evaporated. You may get better results by rubbing alcohol on the surface after drying.

- It is preferable to clean the bed after slightly warming it up to around forty degrees Celsius. A slightly warmed-up bed cleaned with hot water will give you better results.

11. Consider Using Print Bed Adhesives

Print bed adhesives help protect some print bed parts and stabilize the printing process. The process becomes very stable by facilitating a prompt sticking of the first layers.

Good bed adhesives include painter’s blue tape, glue stick, or hairspray. You should avoid applying excess adhesives that may compromise your print process.

12. Use Sandpaper to Make PEI Sheet Rougher

If all your fixing techniques fail, you may consider roughening the PEI surface with sandpaper. But, you should be careful to apply the correct roughness, or you will damage the PEI surface. A textured sheet will give better PLA adhesion results.

Make sure you roughen the entire surface evenly to avoid poor PLA adhesion, which will compromise the results of your prints. Also, ensure you thoroughly clean the surface to remove any residues.

Does Acetone Melt PEI Sheet?

Acetone does not melt the PEI sheet but overusing it can cause damage. That is because your skill in using acetone will determine how it will affect the PEI sheet.

Acetone is recommended in cleaning PEI sheets, but you should use it cautiously since it can damage them. The alternative is to use isopropyl alcohol.

Overusing acetone can brittle and crack the surface of the PEI sheet, and that will force you to replace it.

You should also avoid using acetone if you are going to print with PETG since it may negatively affect the quality of your prints.

Conclusion

Fixing PLA adhesion issues is a simple process if you have the appropriate materials.

Among all the bugs that lead to PLA not sticking to PEI, the main one is an uneven print bed. Before trying any other troubleshooting technique, you should first ensure that the print bed is level.

If you keep getting the same results, you may consider using different materials such as a glass or aluminum bed for your print surface.

Recommended Reading

3D Printing Shells. Useful Guide for Optimal Parameters!

When it comes to 3D printing, there are a lot of terms to learn. One is shell thickness. What exactly are 3D printing shells? How to set optimal parameters?

Is It Legal to 3D Print Legos?

is it legal to 3D print legos? 3D printing lego is illegal. Nonetheless, there are some conditions. However, the interlocking toy bricks are not copyrighted...

How to Start 3D Printing

There's more to beginning a 3D printing venture than getting the necessary materials. So, how to start 3D printing? Follow this useful guide and find out!