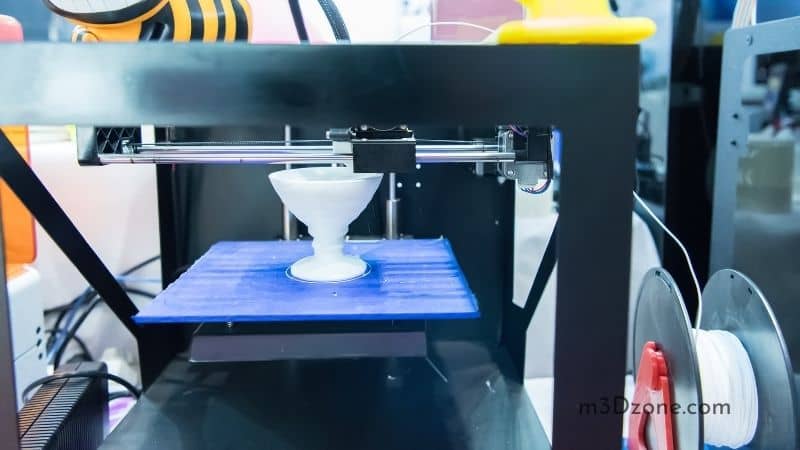

3D printing allows designers to build unique components and complex shapes that would be either expensive or impossible to produce using standard manufacturing processes. Many food-related applications can profit from these advantages.

As an Amazon Associate, I earn from qualifying purchases. If you make a purchase after clicking on a link I may earn a small commission at no extra cost to you.

However, to use 3D printed components in food-contact items, you’ll need to be aware of food-safety rules and practices.

Quick Navigation

That awareness will help you avoid the accumulation of toxic chemicals and dangerous bacteria in them. Continue reading this article to understand how to make 3D print objects food-grade safe.

What Is a Food Safe Coating for 3D Prints?

You can use 3D printing in a broad variety of food-safe materials. Again the choice of materials continues to expand as new ones become printable.

A food-safe coating is critical for manufacturing these 3D models ensuring that the food they handle remains safe.

The manufacturing of these coatings involves the application of a liquid or powder to a product’s surface to impart other qualities.

Certain material types are frequently employed in the fabrication of three-dimensional things. Among them are polymers, such as the most used PLA.

It’s essential to consider several while deciding on your printer’s material. For starters, you should use non-toxic materials for your food containers. So PET or PETG is ideal for this task. If your 3D printed products aren’t functioning, you can use the cheap plastic nylon.

How Do You Make 3D Prints Food Safe? [Food Safety]

Food safe 3D printing may appear challenging at first. However, with the correct know-how, it’s a reasonably straightforward process.

The following is a list of the key considerations to make when ensuring the food safety of your printed objects:

- Use a certified food-safe filament

- Use a steel nozzle on an all-metal hot end

- Cleaning the hot end

- Upgrade to a Capricorn PTFE tube extruder or a direct drive extruder

- Make use of a food-safe coating on the surface (Epoxy)

- Add 100 percent infill to reduce gaps by decreasing the layer heights

Let’s now discuss each of these issues briefly.

Use a Certified Food Safe Filament

For food safety, you can use an approved food safe filament with a Material Safety Data Sheet (MSDS) stating whether the filament is FDA approved.

No two filaments are alike. While many regard PETG and PLA as more food-safe (excluding PLA army green) than ABS or Nylon, they are still not suitable for use with food unless they are certified food safe.

Overture Clear PETG Filament (check at Amazon), for example, is a suitable choice since it has no color additives that might contaminate the filament. Although not FDA-approved, it is regarded as food safe.

Manufacturers commonly add pigments or chemical additives to filaments to increase their strength, durability, or flexibility.

PLA+ is an excellent example of this. To print food-safe 3D objects, use natural PLA without chemical or color additions.

Amazon’s eSun Natural PLA 1 KG Filament is a good starting point. That said, the market boasts of a range of other food-safe filaments. Again besides Amazon, there’s Filaments.ca, among other markets that sell a variety of them.

Further, Taulman Nylon 680 is a premium Nylon filament for FDM 3D printing that’s FDA certified. The product has had many positive reviews. It’s the best solution for mechanical parts that must withstand severe handling.

You also may use Nylon 680 for the 3D printing of mugs and cups. Nylon tolerates high temperatures making it an ideal material for this purpose.

Use a Steel Nozzle on an All-metal Hot End

The majority of budget-friendly 3D printers, like the Creality Ender 3 (check at Amazon), come with a brass extruder nozzle and do not include an all-metal hot end.

Brass nozzles may contain lead, which is deadly when consumed. To ensure the food safety of your 3D prints, I strongly recommend switching to a stainless steel nozzle and using an all-metal hot end.

The MicroSwiss All-Metal Hot-end Kit is a good pick for various 3D printers, including the Ender 3, the CR-10 (check at Amazon), etc.

Cleaning the Hot End

Maintaining a clean hot end should be standard practice for all 3D prints, not just those meant for food.

It is advisable to polish the hot end with a contact brush for approximately 3-4 minutes until it is clean and clear of any remaining filament or visible debris.

The OriGlam 3 Piece Mini Wire Brush set (check at Amazon) includes steel, nylon, and brass brushes. We recommend cleaning the hot end using the brass brush. Assemble the nozzle to your standard 3D printing temperature to soften the filament.

Some individuals even propose heating everything with a heat gun instead of materials close to or touching the hot end. Amazon’s Seekone Hot Air Heat Gun should work fine.

Upgrade to a Capricorn PTFE Tube Extruder or a Direct Drive Extruder

Most 3D printing specialists assert that printing without PTFE tubes is better. That’s because Teflon can disintegrate while printing at extremely high temperatures of between 240°C and 260°C.

You may inspect the PTFE tube in your 3D printer to see whether it has warped or melted in any way.

We’d recommend replacing your standard PTFE tubing with Amazon’s Capricorn PTFE Tubing, which includes updated printer fittings and a tube cutter.

The tubes have substantially better heat resistance and hence do not deteriorate as quickly as standard PTFE tubes.

You should see far fewer difficulties due to this upgrade, which translates to less maintenance in the long term.

Alternatively, you may opt to utilize a Direct Drive extrusion technology that does not require a PTFE tube to ensure the food safety of your 3D printers.

Make Use of a Food-safe Coating on the Surface (Epoxy)

One of the best methods to make parts food safe is to treat them with a food-safe-material coating like epoxy resin. Amazon’s Alumilite Amazing Clear Cast is a top-rated product with a 4.7/5.0 overall rating and many positive reviews.

The product has been used successfully to generate food-safe 3D printing. It’s a two-part transparent coating & casting resin that you combine in a 1:1 ratio.

The standard procedure is to sand the sculpture first to eliminate any threads or debris, then mix equal parts resin and cast. Apply your print with resin and dry it for 3-4 days. Before using the resin, make sure it has fully cured.

Add 100 Percent Infill to Reduce Gaps by Decreasing the Layer Heights

Use slicer settings to help create your food-safe 3D printed products. The primary objective here is to minimize the occurrence of any gaps or cracks that might harbor bacteria.

To assist with this, begin by using a layer height of 0.4mm instead of the typical 0.2mm.

Additionally, you can close such gaps using more significant amounts of infill where it makes sense. Having top and bottom thicknesses, including enough wall, should result in more food-safe versions with no gaps or holes.

Additionally, increasing the Flow Rate to increase the extruded material will result in overlapping layers, causing an even, more waterproof, and sturdy 3D print with no gaps.

How Do You Seal PLA Food Safe?

The best choice to minimize the possibility of particle movement and bacteria growth is by dip coating the 3D print. You may use a polyurethane resin or food-grade epoxy to cover the print’s surface.

These include ArtResin, Masterbond’s EP42HT-2FG, or an FDA-approved PTFE (often referred to as Teflon®) to seal its surface.

However, the coating does not ensure food safety for extended use. That’s because not all coatings are dishwasher safe and may deteriorate over time. This way, they end up exposing the underlying, possibly unsafe surface.

What Epoxy Is Food Safe?

You may render PLA food safe by covering it with an FDA-approved epoxy resin, like Polyurethane (a typical material in the manufacture of plastic bottles and other classic food containers), which is readily available at any local craft store.

It is advisable to print PLA with a stainless steel nozzle (check at Amazon) and utilize food-grade PLA, such as Natural PLA.

The best approach to make PLA food safe is to cover it with a food-grade epoxy resin. PLA has several drawbacks, though. The most notable of these is that they are less robust and not very heat resistant.

While you may locate one in a shop near you, some excellent alternatives are available online.

The ideal food-safe coating for 3D prints is a food-grade epoxy resin that you can cover your model’s layer lines. Another idea is by applying food-grade silicone to the model making.

Is There a Food Grade Resin?

You’ve certainly seen incredible countertops, dining tables, and kitchenware with finishes that look as if they’ve been splashed with a bit of ocean of color.

A synthetic resin mainly employed as an adhesive component is the secret behind this trick. Cured resins such as ZDSticky and Art Resin provide an ideal food-safe epoxy.

The resins are FDA-approved and don’t contain any volatile organic compounds. As a result, they are an excellent alternative for treating any hardwood surfaces or kitchen counters.

This implies that when the cured resin is utilized, it will not leach harmful chemicals into the food with which it comes into contact.

Conclusion

Users may now easily create functional cooking equipment at home using 3D printing.

The most significant concern relating to 3D printed objects is food safety since even the finest prints have microscopic cracks and crevices where bacteria may gather and flourish.

If you want to design 3D print objects that will come into touch with food – look no further than the complete list of what you need to consider to ensure food safety during the printing process.

Recommended Reading

What Is a Resin 3D Printer?

So, what is a 3D resin printer? A resin 3D printer is a machine that uses light to convert models to prints. By directing UV light onto resins ...

PLA Not Sticking to PEI? Easy Fixes and Useful Guide!

PLA not sticking to PEI? Wel, the starting point is to have an effective first layer in your 3D prints. A proper bed adhesion on your 3D printer is a must!

3D Printing Shells. Useful Guide for Optimal Parameters!

When it comes to 3D printing, there are a lot of terms to learn. One is shell thickness. What exactly are 3D printing shells? How to set optimal parameters?